Method and device for obtaining cold rolling temper rolling pressure

A technology of rolling pressure and temper rolling, which is applied in the field of acquisition of cold rolling temper rolling pressure, can solve problems such as inability to accurately evaluate mathematical models, and achieve the effect of stable iterative calculation and clear principles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

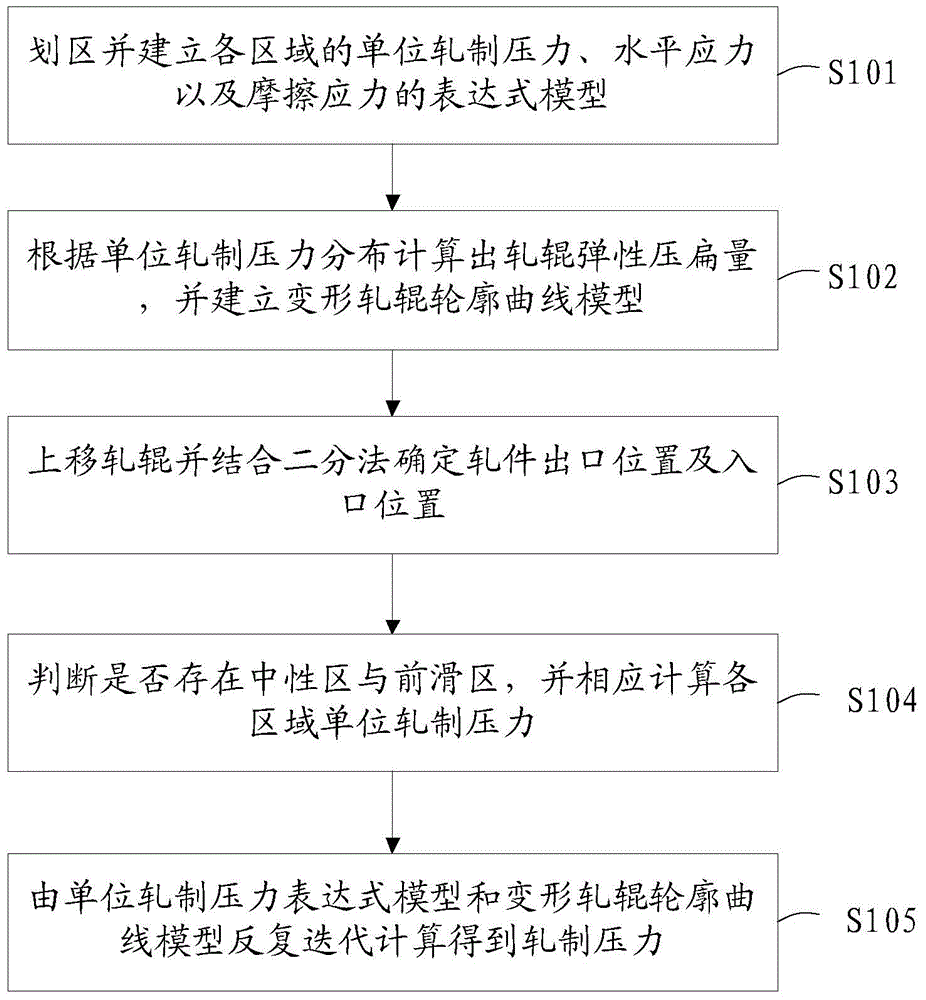

[0031] figure 1 The flowchart of the method for obtaining the tempering rolling pressure of cold rolling provided by the embodiment of the present invention is shown, and only the parts related to the embodiment of the present invention are shown for convenience of description.

[0032] Such as figure 1 As shown, the method for obtaining the cold-rolled temper rolling pressure provided in this embodiment includes the following steps:

[0033] Step S101, divide the roll gap deformation area into five areas, which are the entrance elastic deformation area, the rear slip area, the neutral area, the front slip area and the exit elastic recovery area, and establish the unit rolling pressure, horizontal stress and Expression model for frictional stress.

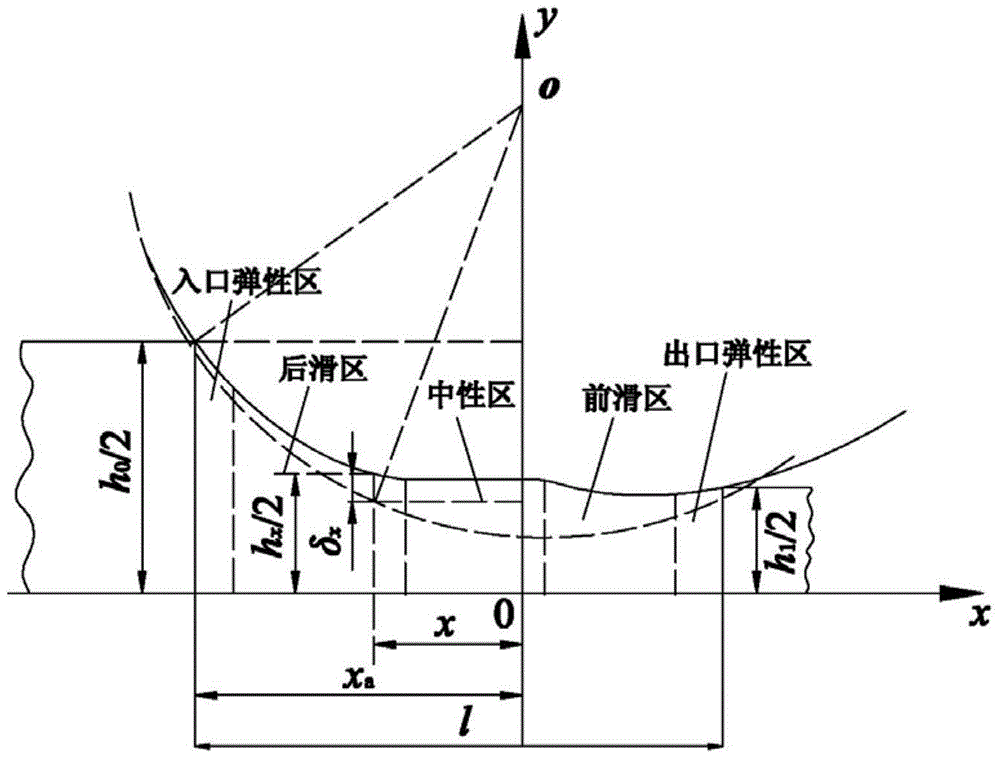

[0034] Such as figure 2 As shown, from the entrance position to the exit position, the roll gap space is divided into five areas in turn: the entrance elastic deformation area, the rear slip area, the neutral area, the front sl...

Embodiment 2

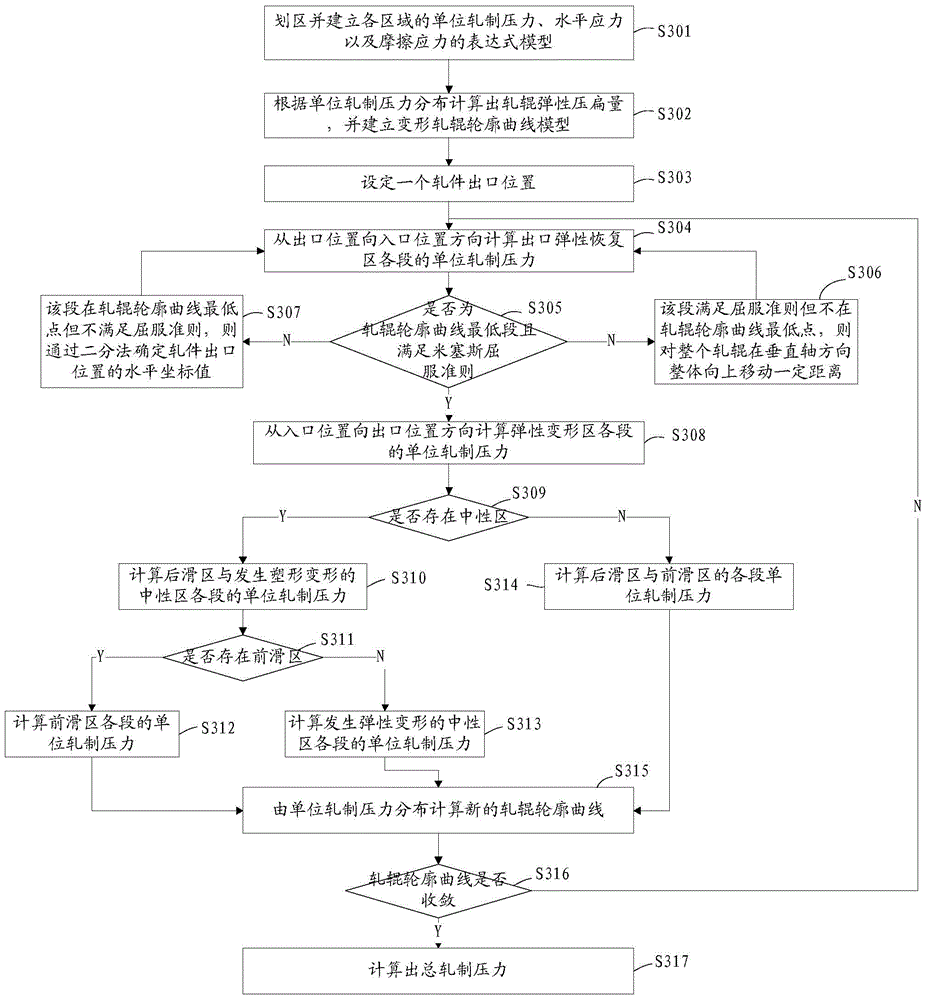

[0089] image 3 The flowchart of the method for obtaining the tempering rolling pressure of cold rolling provided by the embodiment of the present invention is shown, and only the parts related to the embodiment of the present invention are shown for convenience of description.

[0090] Such as image 3 As shown, the method for obtaining the cold-rolled temper rolling pressure provided in this embodiment includes the following steps:

[0091] Step S301, divide the roll gap deformation area into five areas, which are the entrance elastic deformation area, the rear slip area, the neutral area, the front slip area and the exit elastic recovery area, and establish the unit rolling pressure, horizontal stress and The expression model of friction stress;

[0092] Step S302, calculating the elastic flattening amount of the roll according to the distribution of the unit rolling pressure, and establishing a profile curve model of the deformed roll.

[0093] The above two steps are t...

Embodiment 3

[0197] Figure 8 The structure of the device for acquiring the tempering rolling pressure of cold rolling provided by the embodiment of the present invention is shown, and only the parts related to the embodiment of the present invention are shown for convenience of description.

[0198] Such as Figure 8 As shown, the acquisition device of the cold-rolled temper rolling pressure provided in this embodiment includes:

[0199] The zone modeling unit 81 is used to divide the roll gap deformation zone into 5 zones, which are the entrance elastic deformation zone, the rear slip zone, the neutral zone, the forward slide zone and the exit elastic recovery zone, and establish the unit rolling area of each zone. Expression models of restraining pressure, horizontal stress and frictional stress;

[0200] The contour curve modeling unit 82 is used to calculate the elastic flattening amount of the roll according to the unit rolling pressure distribution, and establish the contour cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com