Single-station punching mechanical arm structure

A manipulator and single-station technology, applied in the field of stamping equipment, can solve problems such as easy work-related injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

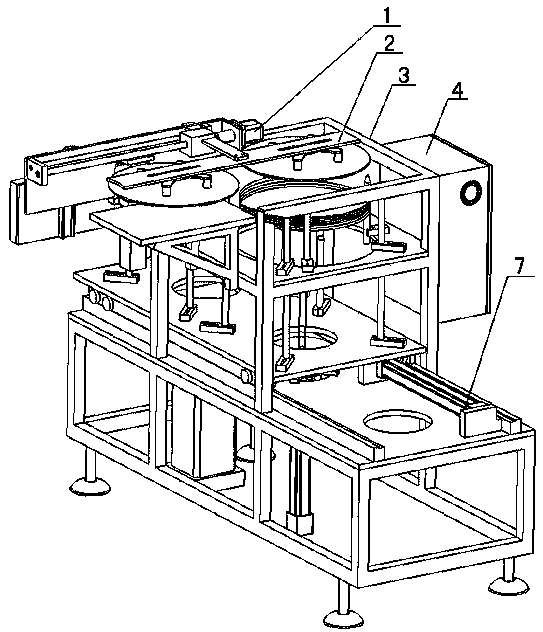

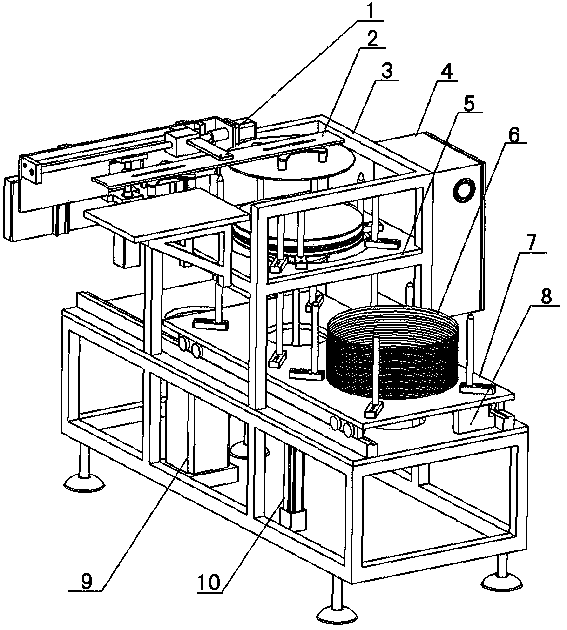

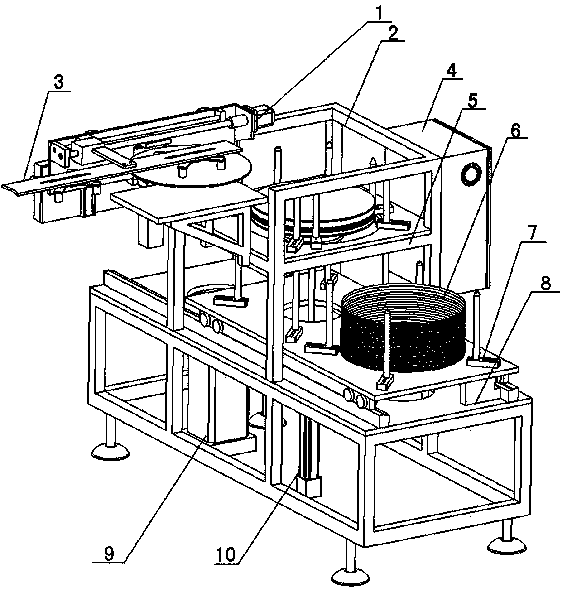

[0023] like Figure 1-8 As shown, the single-station stamping manipulator structure described in the embodiment of the present invention includes a frame power device 1, a feeding frame 2, and a main frame body 3, and the main frame body 3 is composed of an upper frame body and a lower frame body , where the top of the upper frame body is equipped with a feeding frame 2 and connected to the frame power unit 1 at one side of the feeding frame 2, and the middle part of the upper frame body is provided with a material positioning frame 5, and the surface of the lower frame body below the material positioning frame 5 is horizontal Lay a stocking frame 7 and fixedly install a horizontal cylinder 8 in the space between the bottom surface of the stocking frame 7 and the upper surface of the lower frame body, wherein the upper material cylinder 10 is installed in the main frame body 3 below the stocking frame 7, so An oil reservoir 9 is installed inside the lower frame body; meanwhile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com