Large vibration force large amplitude vibrating squeeze casting method and casting device thereof

A vibration device and squeeze casting technology, applied in the field of casting methods and equipment, can solve the problems of large energy consumption, large hydraulic system of equipment structure, large extrusion force, etc., and achieve the effect of high frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

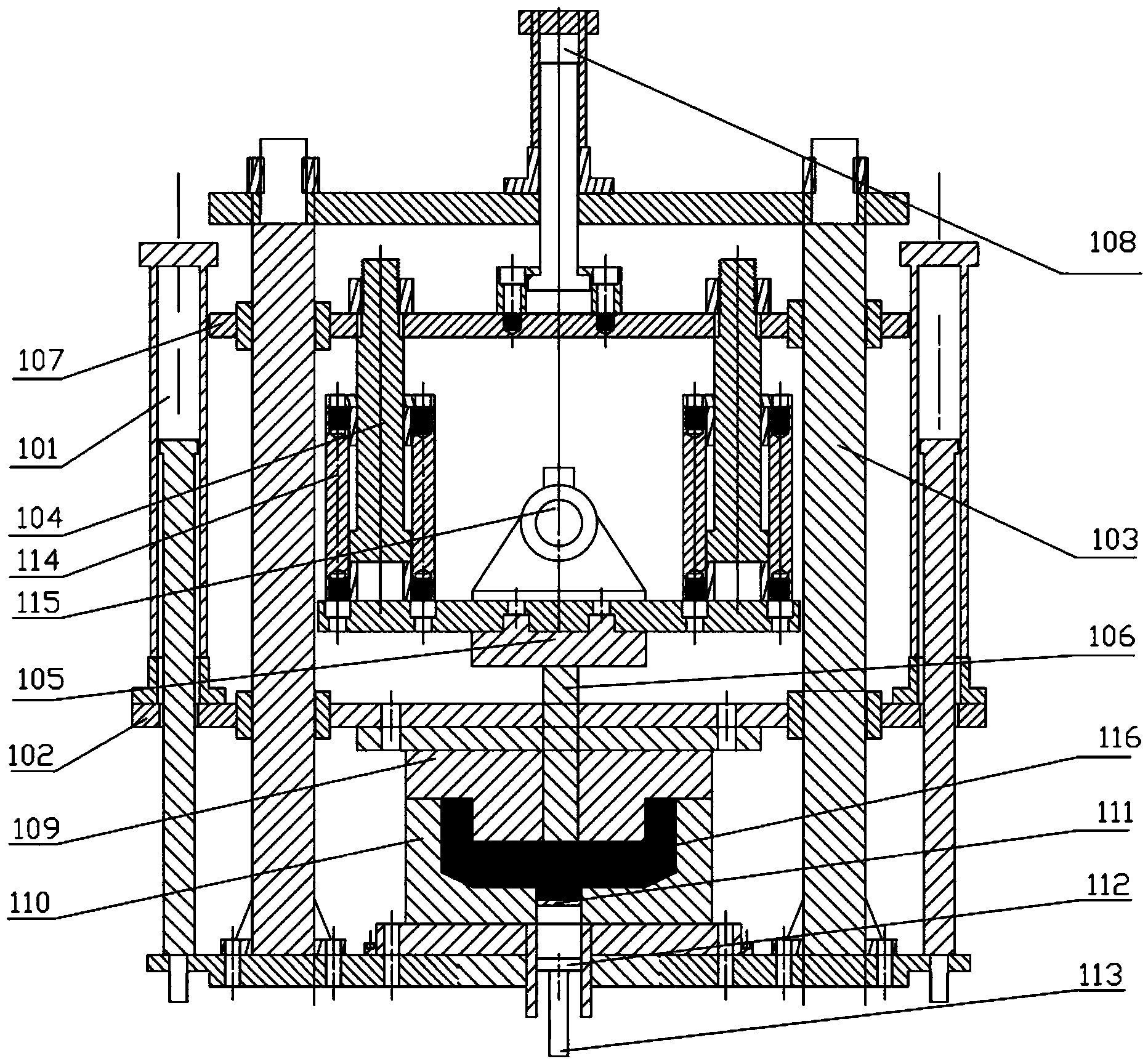

Embodiment 1

[0034] The vibration squeeze casting method with large vibration force and large amplitude described in this embodiment is as follows:

[0035] First, a vibrating rod is inserted into the casting mold, and the vibrating rod is applied with a vibration pressure of large vibration force and large amplitude by a vibration exciter (specifically, a large vibration force and large amplitude mechanical or electromagnetic vibration generator), and It can transmit the large vibration force and large amplitude vibration pressure applied to it to the formed metal material in the cavity of the casting mold, and provide a vibration pressure field for the formed metal material to directly act on the formed metal material itself; when When casting is required, the movable mold and the fixed mold in the casting mold are molded together to form a mold cavity, and then the required molded metal material is injected into the mold cavity, and finally by applying a large vibration to the vibrating ...

Embodiment 2

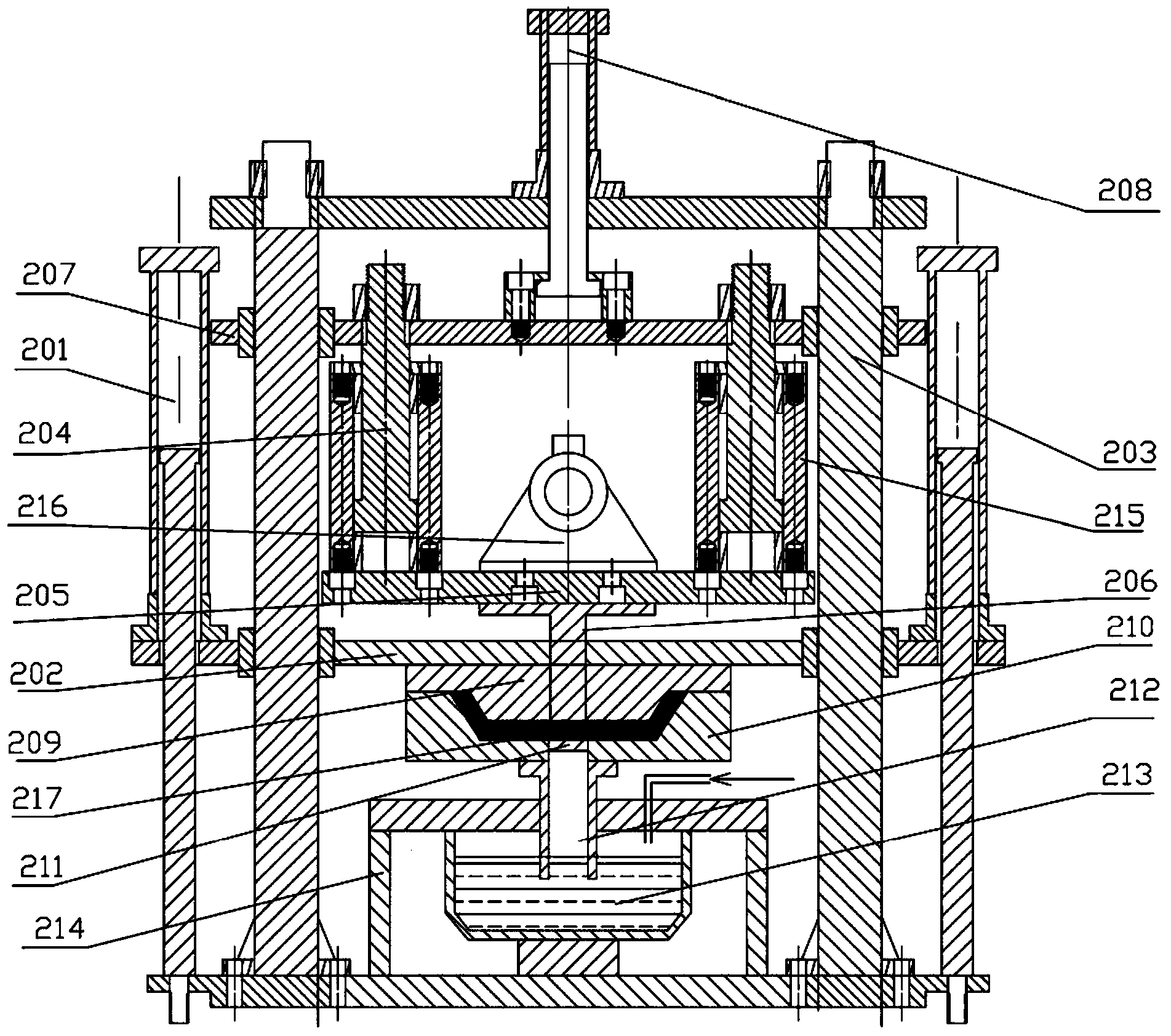

[0040]Such as figure 2 As shown, the difference from Embodiment 1 is that the mold opening and closing device of this embodiment includes a mold opening and closing hydraulic cylinder 201 for controlling mold opening and closing, a movable mold seat plate 202, and a guide column 203. The large vibration force is large The amplitude vibration device part includes movable guide rod 204, promotes pressing plate 205, vibrating rod 206, vibration push plate 207, push plate hydraulic cylinder 208, vibration motor 216, and described casting mold device part includes movable mold 209, fixed mold 210, Runner cut-off plate 211, liquid riser 212, container 213 for holding the metal material to be formed, and holding furnace 214, wherein the movable mold seat plate 202 is movably fitted on the guide column 203, and is controlled by the mold opening and closing hydraulic cylinder 201 Control the up and down movement; the movable mold 209 and the fixed mold 210 face up and down, the movabl...

Embodiment 3

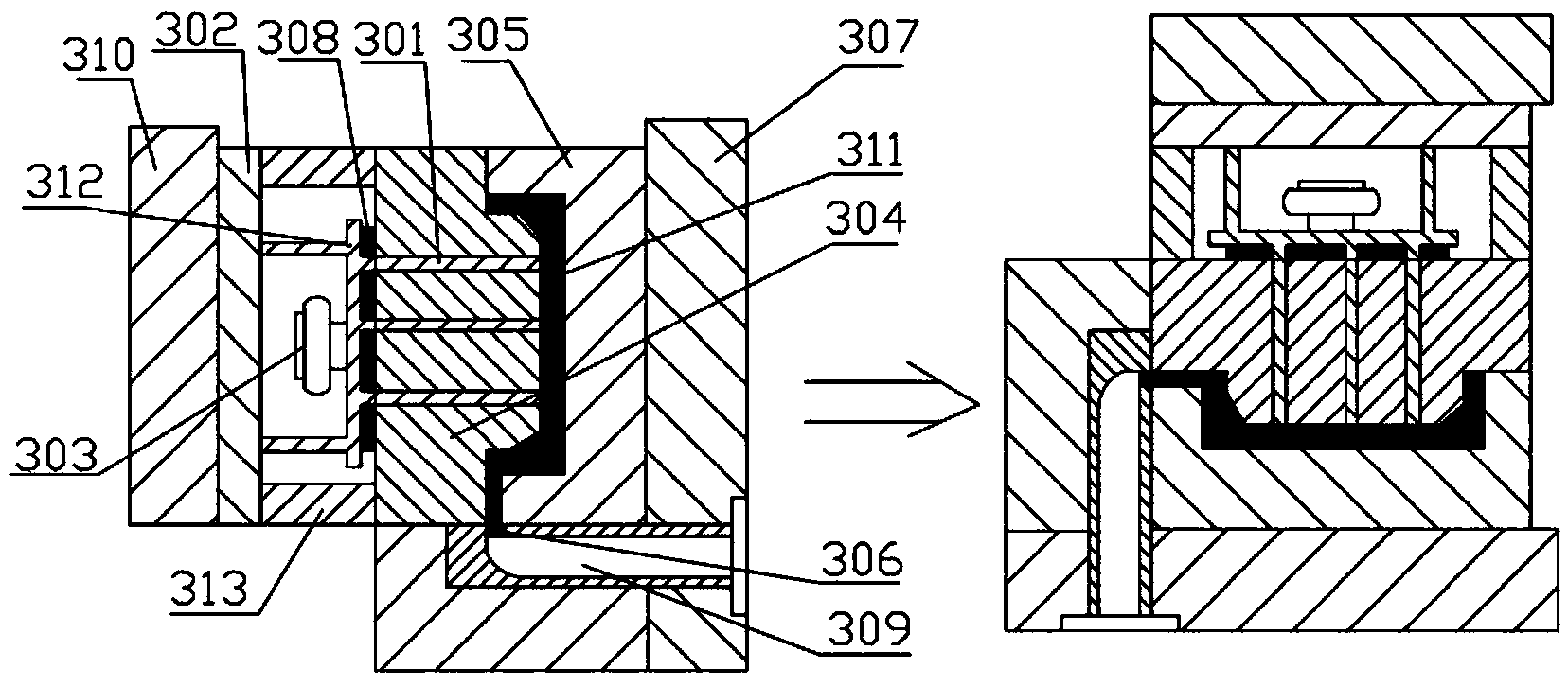

[0043] Such as image 3 As shown, the difference from Embodiment 1 is that the mold opening and closing device part of this embodiment includes a mold opening and closing hydraulic cylinder for controlling mold opening and closing, and a movable mold seat plate 310. The vibration device with large vibration force and large amplitude includes Vibrating bar 301, vibrating push plate 302, vibrating motor 303, pressing plate 312 are arranged, and the casting mold device part can be turned over 90° as a whole, so that the fixed mold seat plate 307 is in contact with the ground, and it includes a movable mold 304, a fixed mold 305, Runner cut-off plate 306, fixed mold base plate 307, elastic gasket 308, wherein, the movable mold base plate 310 is controlled to move left and right by the mold opening and closing hydraulic cylinder, and the movable mold 304 and the fixed mold 305 are opposite to each other and can be combined A mold cavity 311 is formed, and the movable mold 304 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com