U-shaped offshore engineering installation vessel and jacket topside module installation method

A technology of marine engineering and installation method, which is applied in the direction of hull parts, hulls, ship construction, etc., can solve the problems of poor wind and wave resistance, restrictions, and large amplitude of violent movement, etc., to achieve strong wind and wave resistance, improve sea resistance, Good ship shape stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

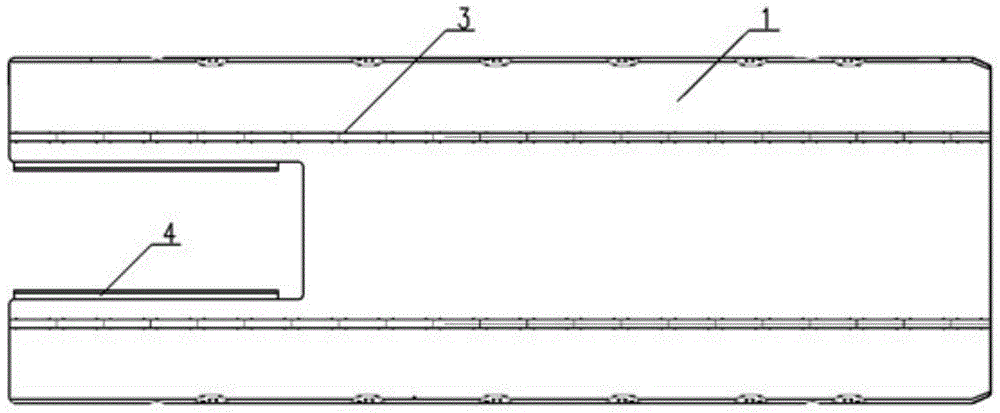

[0017] figure 1 Shown is the "U" type marine engineering installation ship of the present invention. The "U" type installation ship hull 1 includes a U-shaped groove part 2 at the stern and a midship part 3 at the bow. On the deck of the hull 1, a through installation ship 1 is installed. The slide rail 4 of the stern "U" groove 2 inboard fender device 5 is installed.

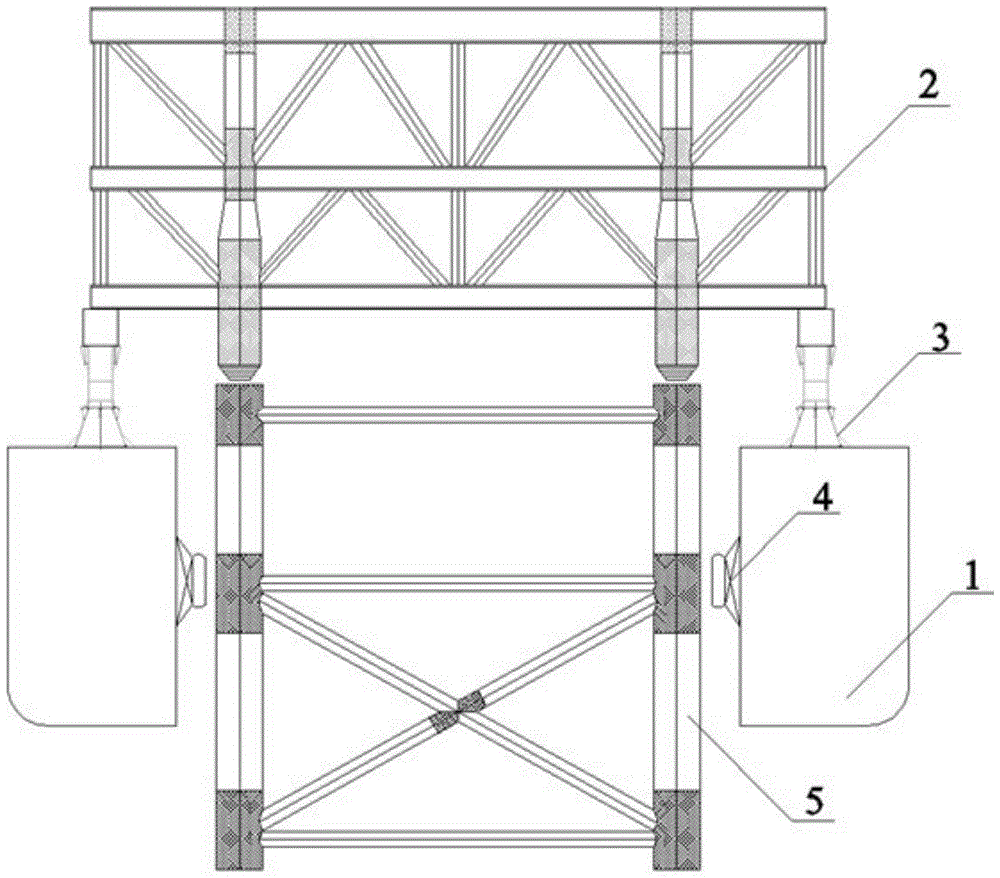

[0018] The "U"-shaped offshore engineering installation vessel provides a new form of external floating towing installation for the installation of the upper part of large platforms. see figure 2 Its installation process is as follows:

[0019] 1. The upper module 6 of the platform is transferred from the bow of the "U" type installation ship 1 to the installation ship along the slide rail 4 through the traction device at the dock. During the transfer process, the floating state of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com