Film coil thickness accumulation control system

A control system and film technology, applied in the direction of winding strips, thin material processing, transportation and packaging, etc., can solve the problems of film roll bulging, strong customer complaints, and the edge locker can not meet the predetermined flexible operation requirements. The effect of improved thickness accumulation and simple control of roll displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

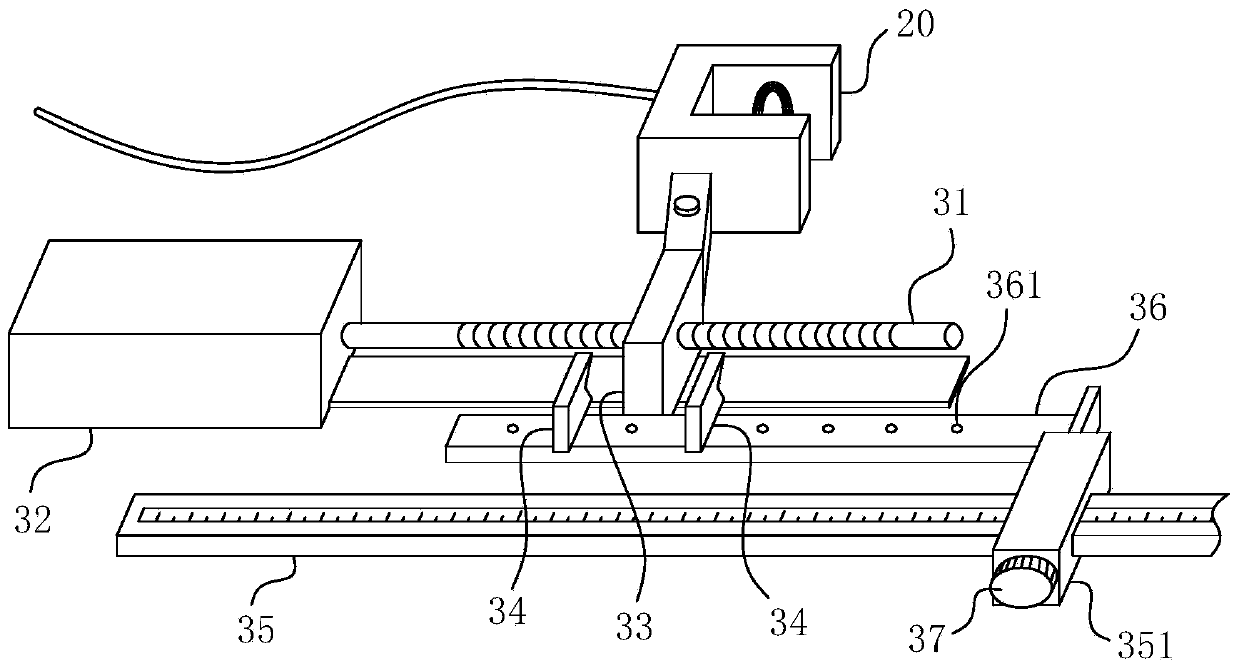

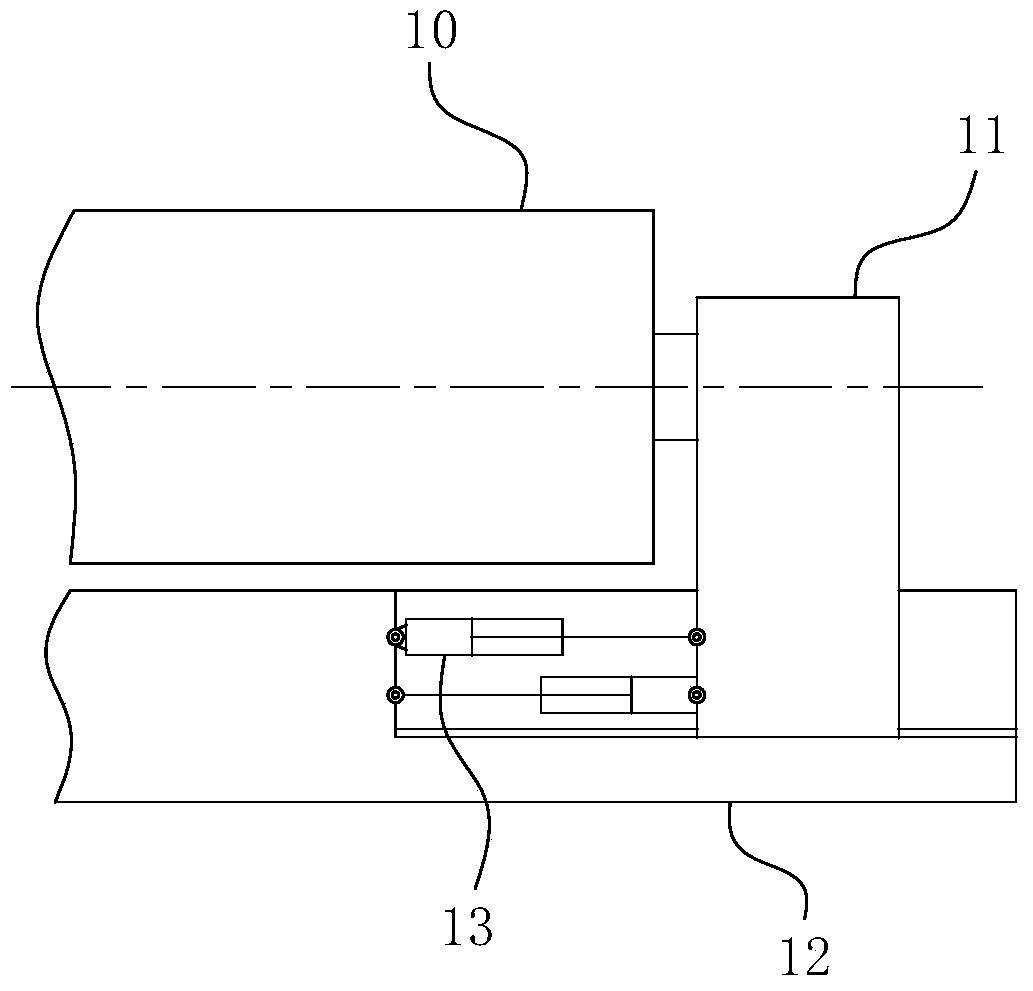

[0026] For ease of understanding, combine here Figure 1-2 The specific structure and working mode of the present invention are described as follows:

[0027] The specific structure of the present invention is as Figure 1-2 As shown, it includes the existing edger 20 and related control components, and uses the film surface slippage sensed by the edger 20 as a signal to control the roller 10 to produce a reciprocating effect along its axial direction, and finally Realize the corrective effect for the film movement slip. On the basis of the above structure, the present invention adds a drive mechanism capable of reciprocating linear motion, such as figure 1 The screw-rod slider mechanism shown, etc., uses the screw rod 31 as the driving rod of the slider 33, and the slider 33 is fixed to the edge locker 20 and formed a threaded fit with the screw rod 31; at the same time, the stroke of the slider 33 The travel switch 34 is arranged on both sides to limit the reciprocating movem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com