Fermentation device for rapid decomposition of livestock and poultry manure and its application method

A fermentation device, livestock and poultry manure technology, applied in fertilization devices, applications, organic fertilizers, etc., can solve problems such as non-point source pollution, and achieve the effects of accelerating fermentation speed and quality, convenient cleaning, and promoting biological enzyme activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Description of the construction of the device

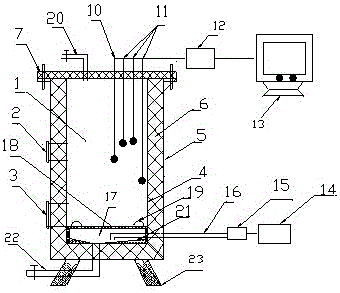

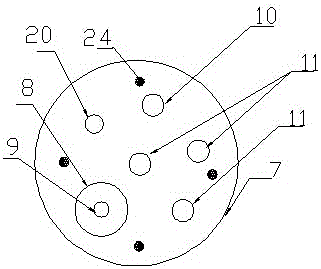

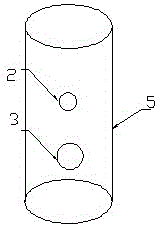

[0050] to combine Figure 1-3 , a fermentation device for rapid decomposing of livestock and poultry manure. The shape is a hollow cylinder, including five major systems: fermentation system, monitoring system, ventilation system, leachate system and heat preservation system. The fermentation system includes a fermentation chamber 1, a sampling port 2, a discharge port 3, an inner cylinder 4, an outer cylinder 5, an insulation layer 6, a flange sealing insulation cover 7, a feed inlet 8, a perspective hole 9, a bracket 23 and a fixing nut 24 , also includes various holes opened for other systems; the monitoring system includes a humidity gas sensor 10, a temperature pressure sensor 11, a data converter 12 and a display microcomputer 13; the ventilation system includes a blower 14, a thermostat, a time controller, a pressure control Device and flowmeter 15, air distribution pipe 16, air distribution chamber 17, air distrib...

Embodiment 2

[0056] How to use the fermentation device

[0057] 1. Raw material pretreatment

[0058] According to the principle of dry and wet, mix livestock and poultry manure, bacteria and other auxiliary materials evenly, so that the carbon-nitrogen ratio of the fermentation material reaches 25-30:1, and the moisture reaches 55-60%. The livestock and poultry manure mentioned above refers to the manure produced by livestock and poultry such as cattle, pigs, chickens, sheep, horses, and ducks; Streptomyces microflavus, Trichoderma longbrachiatum and Bacillus mucilaginosus. Other auxiliary materials refer to mushroom slag, lignite, etc.; the weight-number ratio of livestock and poultry manure: other auxiliary materials: bacterial strains is 80:19.9:0.1.

[0059] 2. Preparation before loading

[0060] Before loading, it is necessary to make some preparations for the fermentation device. First, insert the flange insulation plug equipped with a sealing ring into the sampling port and the d...

Embodiment 3

[0070] Application effect of fermentation device

[0071] The following is the application test of the fermentation device used for rapid decomposing of livestock and poultry manure in improving the degree of decomposing, available nutrients and bacteria count, and shortening the fermentation time.

[0072] The raw material is chicken manure + cow dung at a weight ratio of 1:1, and the auxiliary material is mushroom dregs and lignite at a weight ratio of 1:1, wherein the weight ratio of livestock and poultry manure: auxiliary material: bacterial strain is 80:19.9:0.1, and the water content is 55 % to 60%, the volume is 170L, the room temperature is 25°C, and there are 4 treatments. Treatment 1: aerobic fermentation with temperature and pressure control in the device of the invention; treatment 2: aerobic fermentation with temperature control in the device of the invention; treatment 3: natural (without temperature control) pressure) aerobic fermentation; treatment 4: natural ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com