A kind of high temperature resistant thermosetting shape memory polyimide and preparation method thereof

A polyimide, warming technology, applied in the field of smart material shape memory polymers, can solve the problems of SMP thermal stability and low thermodynamic performance at high temperature, and achieve excellent heat resistance, fast recovery rate, and small modulus change Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

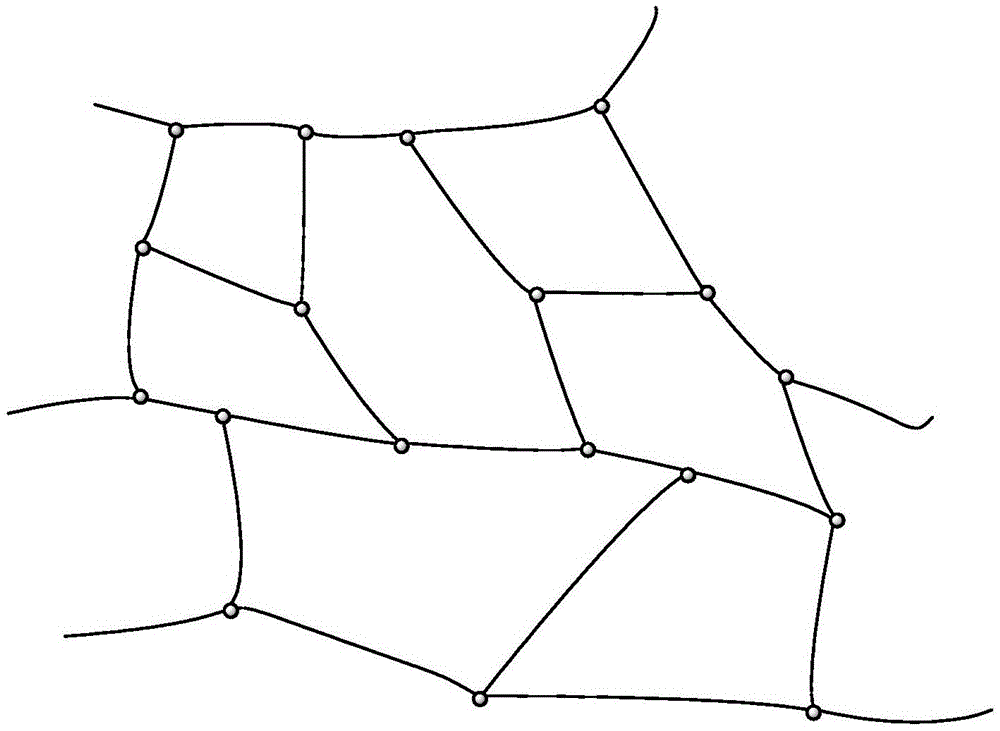

Image

Examples

specific Embodiment approach 1

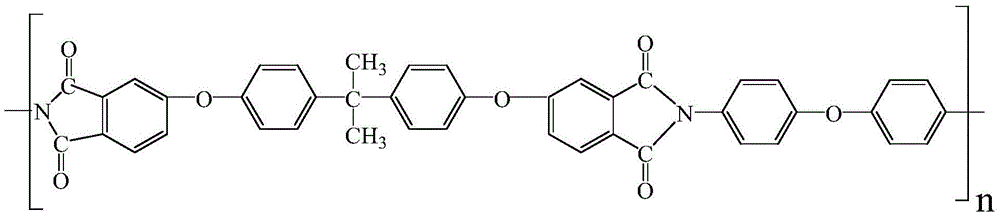

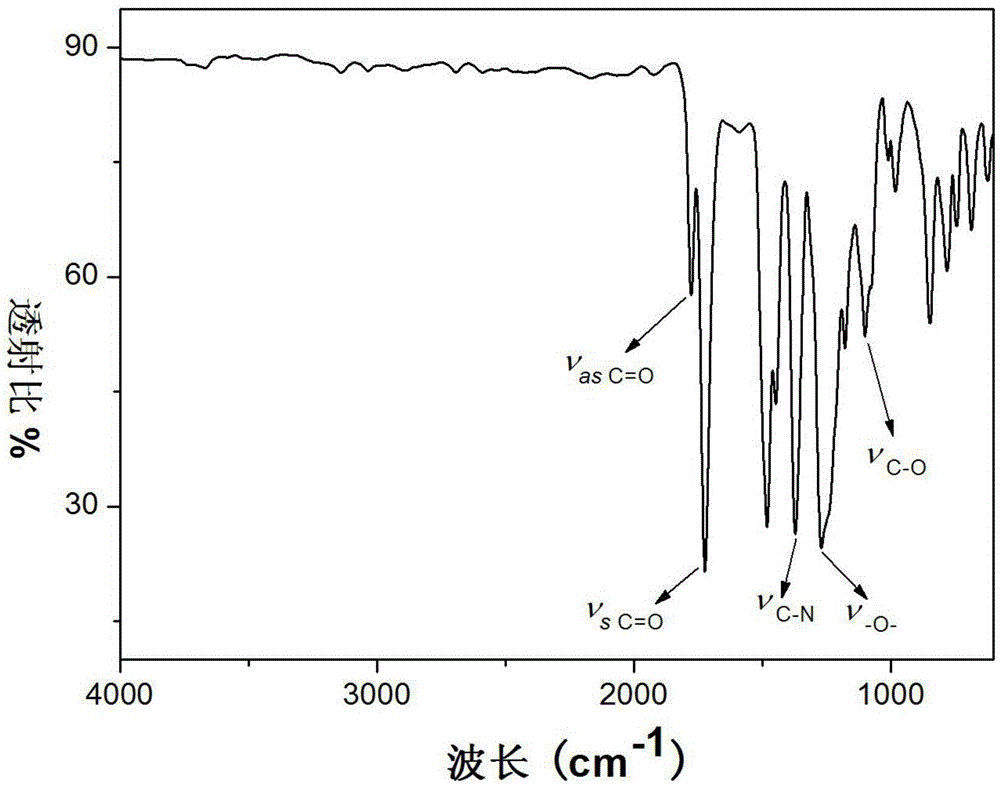

[0038] Specific embodiment one: a kind of high temperature resistant thermosetting shape memory polyimide of this embodiment, its structural formula is:

[0039]

[0040] Wherein, the n is 62-155, and the molecular weight of the polyimide between two triamino cross-linking agent molecules of the high-temperature-resistant thermosetting shape-memory polyimide is 42.3-105.9 kg / mol.

specific Embodiment approach 2

[0041] Specific embodiment two: this embodiment is the same as specific embodiment one: the n is 80-120, the high temperature resistant thermosetting shape memory polyimide is between two triamino crosslinking agent molecules The molecular weight of polyimide is 50-100kg / mol. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0042] Specific embodiment three: a kind of preparation method of high temperature resistant thermosetting shape memory polyimide of the present embodiment, it is carried out according to the following steps:

[0043] 1. Weigh 4,4'-diaminodiphenyl ether diamine monomer into a three-necked flask containing N,N-dimethylacetamide solvent, stir for 30 minutes under the protection of dry nitrogen and room temperature, until completely dissolved , to obtain a solution; wherein, the volume molar ratio of N,N-dimethylacetamide solvent to 4,4'-diaminodiphenyl ether diamine monomer is 1mL: (0.2~0.3)mmoL;

[0044] 2. Weigh the bisphenol A diether dianhydride monomer, and add the bisphenol A diether dianhydride monomer into the solution obtained in step 1 in 4 to 6 times to make 4,4'-diaminodiphenyl The amount of ether diamine monomer substance is 86.5-95.5% of the amount of bisphenol A diether dianhydride monomer substance, and then at room temperature, stir at a stirring speed of 250r / m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com