A kind of rapid solidification preparation method of ultra-high-strength plastic tininbmo shape memory alloy

A memory alloy and ultra-high-strength technology, applied in the field of functional materials, can solve the problems that the strength, plasticity and memory effect are difficult to balance, and the comprehensive performance has not been significantly improved, so as to improve solid solubility, good compactness, and reduce eutectic The effect of organizational formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] In a specific embodiment, the rapid solidification preparation method of the ultra-high-strength plastic TiNiNbMo shape memory alloy of the present invention, the specific process steps are as follows:

[0028] (1) Cut out sufficient quality TiNiNbMo shape memory alloy according to the size of the copper mold, and treat the surface of the alloy, then use acetone and alcohol to perform ultrasonic cleaning, dry and remove water for later use;

[0029] (2) Put the pretreated alloy material into a vacuum electric arc furnace, and heat it under the protection of argon until it melts completely;

[0030] (3) Keep the molten alloy in a quartz tube for 1 to 3 hours to ensure that the composition of the alloy is uniform and minimize segregation;

[0031] (4) The molten alloy is sucked into the water-cooled copper mold to cool under the pressure difference between the vacuum tube and the molten pool, and the mold is opened and taken out.

[0032] Wherein, the composition of the ...

Embodiment 1

[0035] In this embodiment, the ingot size is designed to be Φ8×60mm, and 45g of TiNiNbMo shape memory alloy is cut out, and its composition ratio is Ti: 46.1at%, Ni: 43.4at%, Nb: 9at%, and the balance is Mo.

[0036] The surface of the sample is descaled, cleaned with acetone and alcohol, and dried; the dried alloy material is placed in a vacuum electric arc furnace, heated to a molten state under the protection of argon, and repeated 5 to 6 times ; Keep the molten metal at 1450°C for 1 hour to fully homogenize the alloy; properly increase the temperature to 1500°C to improve the fluidity of the molten metal, and the molten alloy is sucked into the water-cooled copper mold quickly under the pressure difference between the vacuum tube and the molten pool Cooling (this embodiment cooling rate is 10 3 K / s), open the mold and take it out.

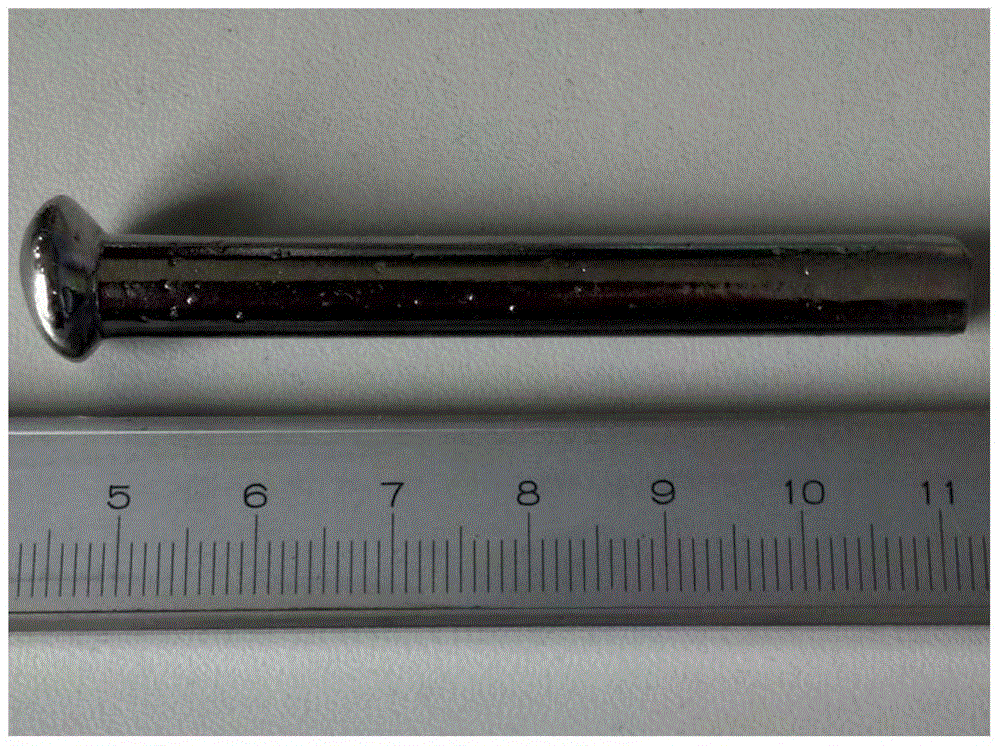

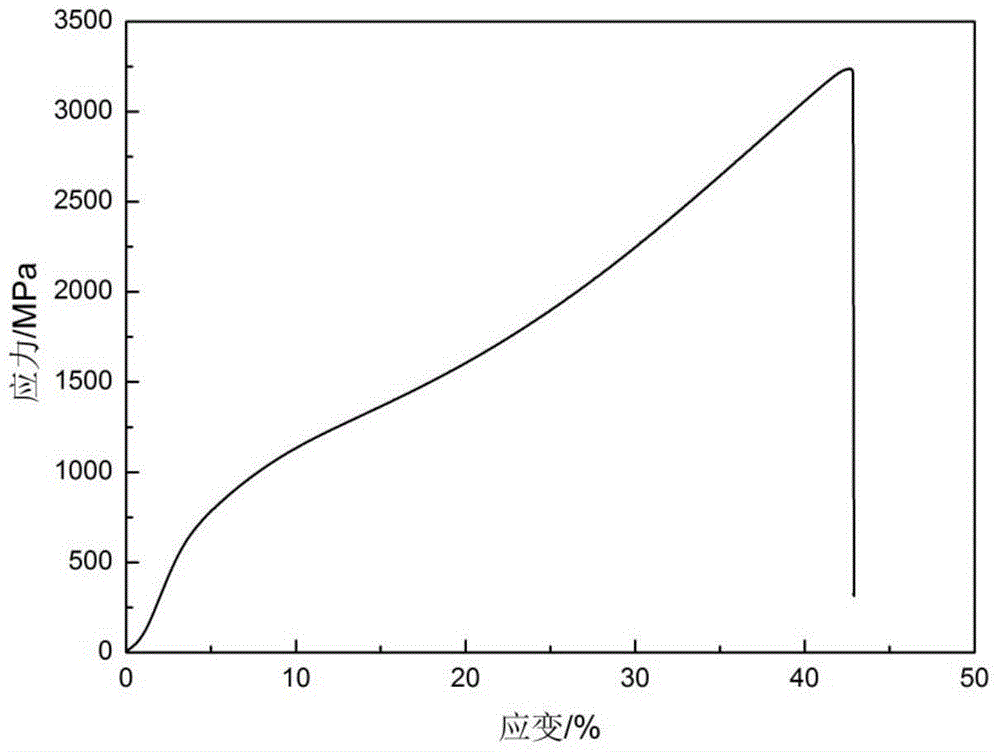

[0037] Such as figure 1 As shown, Ti made from copper mold vacuum suction casting method 46.1 Ni 43.4 Nb 9 Mo 1.5 It can be seen from th...

Embodiment 2

[0043] In this embodiment, the ingot size is designed to be Φ8×60mm, and 45g of TiNiNbMo shape memory alloy is cut out, and its composition ratio is Ti: 47at%, Ni: 45.5at%, Nb: 6at%, and the balance is Mo.

[0044] The surface of the sample is descaled, cleaned with acetone and alcohol, and dried; the dried alloy material is placed in a vacuum electric arc furnace, heated to a molten state under the protection of argon, and repeated 5 to 6 times ; Keep the molten metal at 1400°C for 2 hours to fully homogenize the alloy; properly increase the temperature to 1450°C to improve the fluidity of the molten metal, and the molten alloy is sucked into the water-cooled copper mold quickly under the pressure difference between the vacuum tube and the molten pool Cooling (this embodiment cooling speed is 10 3 K / s), open the mold and take it out.

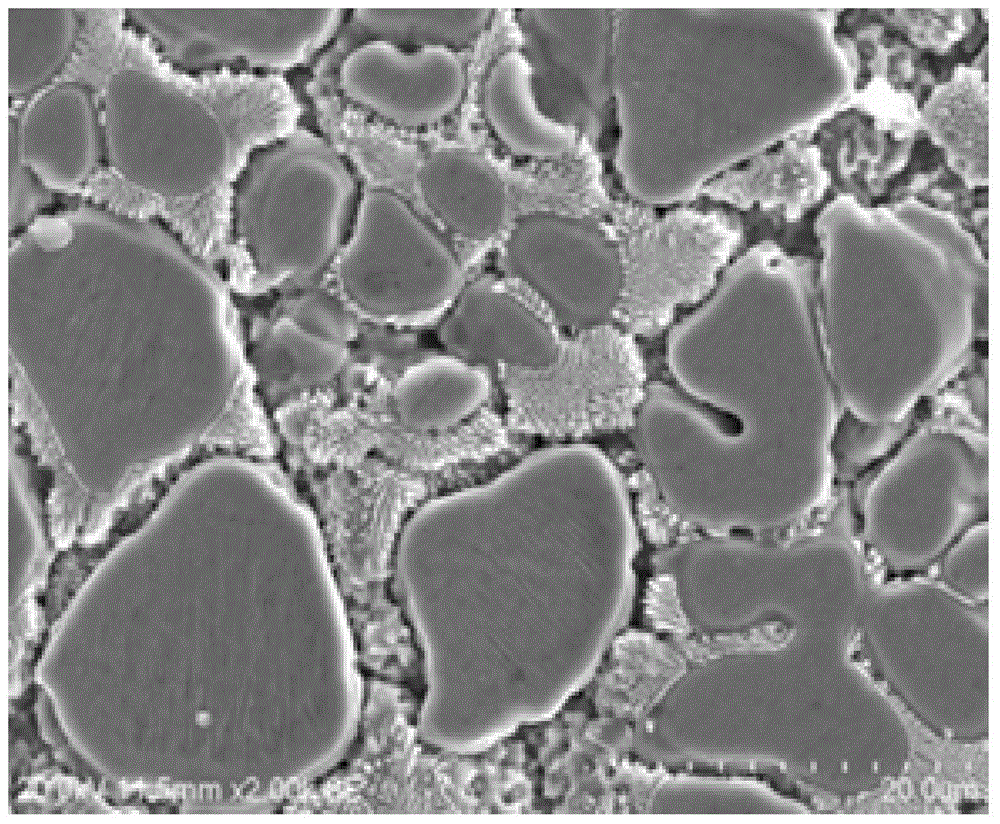

[0045] Such as Figure 5 As shown, from Ti 47 Ni 45.5 Nb 6 Mo 1.5 It can be seen from the microstructure photos of the alloy that, compa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive yield strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com