Vacuum preloading solidification drainage channel

A technology for drainage channels and drainage pipes, which is applied in basic structure engineering, soil protection, construction, etc., can solve problems such as negative pressure value drop, drainage plate bending deformation, etc., to avoid waste, ensure project progress, and speed up drainage rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

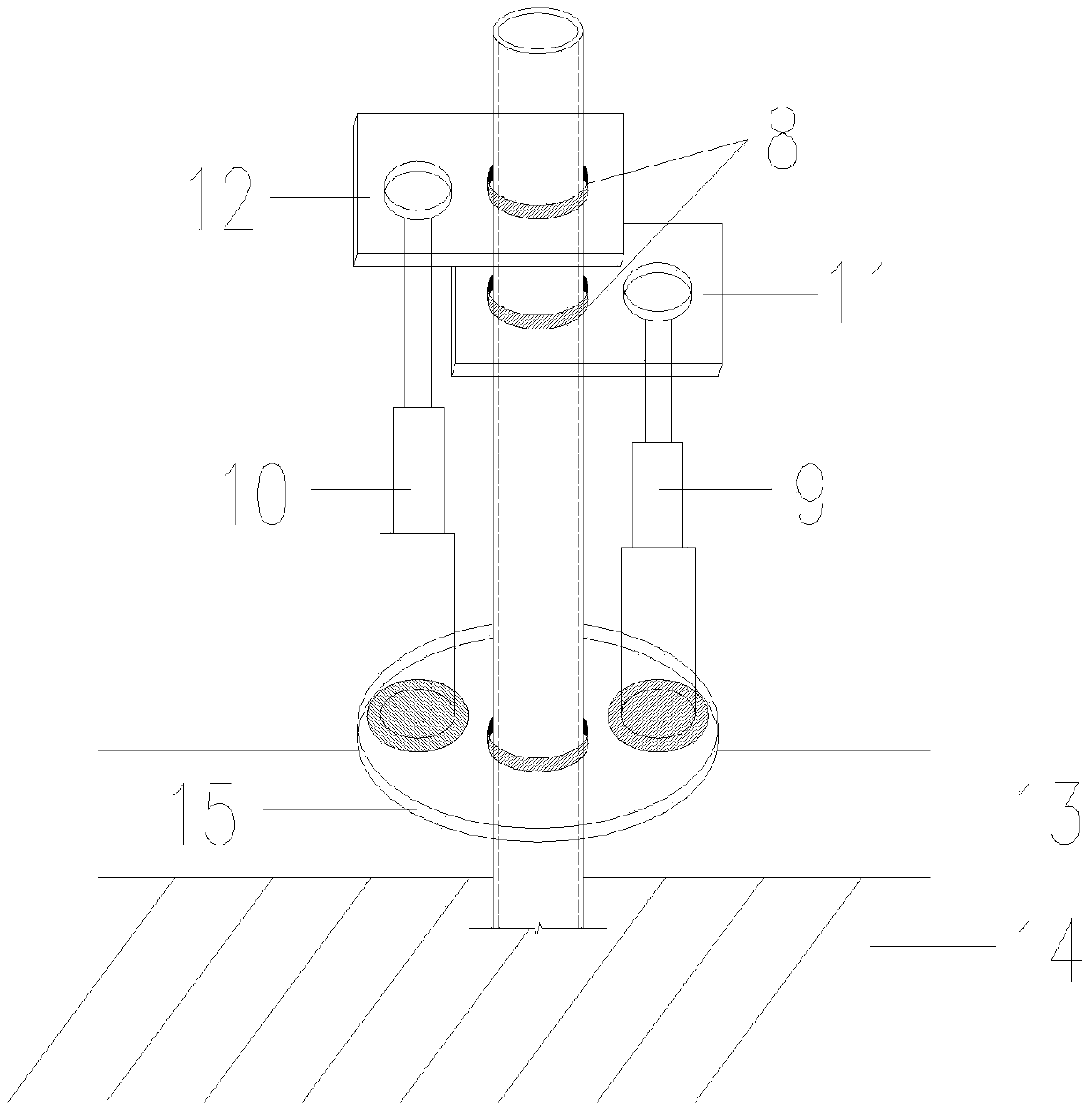

[0012] The present invention will be described below in conjunction with the accompanying drawings and embodiments.

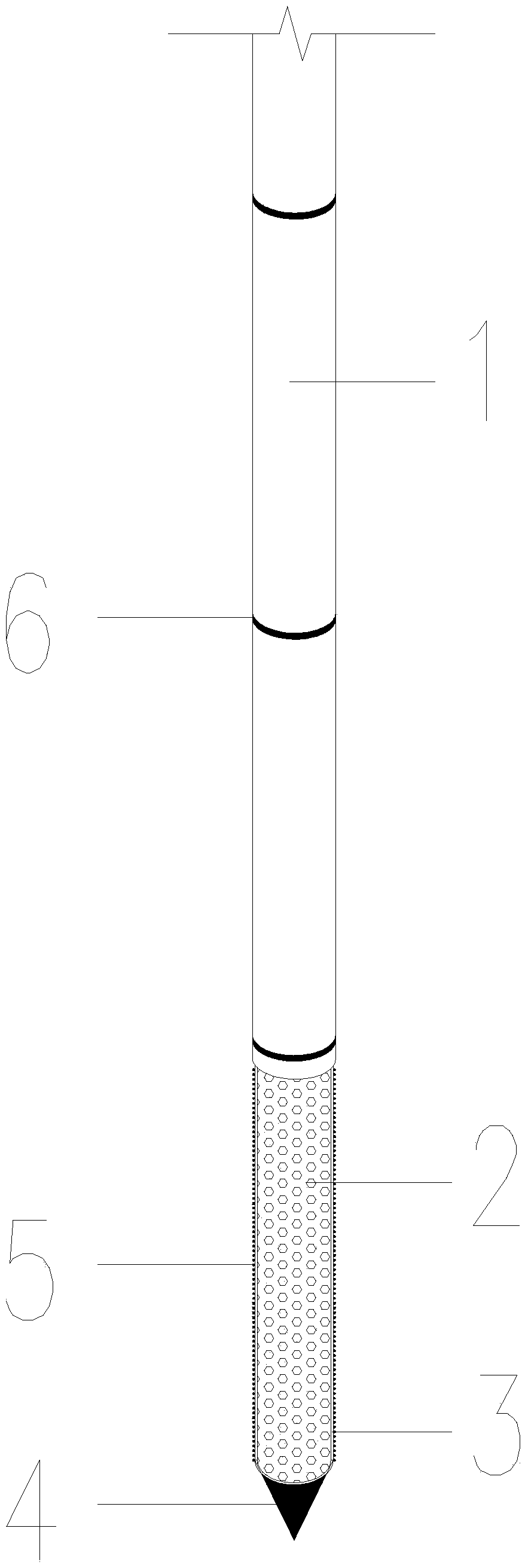

[0013] The present invention improves the existing vacuum preloading drainage technology, and adopts an iron high-rigidity round pipe as a drainage channel, but it only transmits negative pressure and does not discharge sludge. The water in the silt enters the entire longitudinal drainage channel from the lowermost drainage circular pipe, and is discharged from the soil surface through the drainage channel. During construction, the bottom layer of silt is drained and consolidated first (each layer of silt is 2 meters long). After the consolidation is completed, the drainage channel is pulled up to drain and consolidate the upper layer of silt until all layers of silt are drained and consolidated. until.

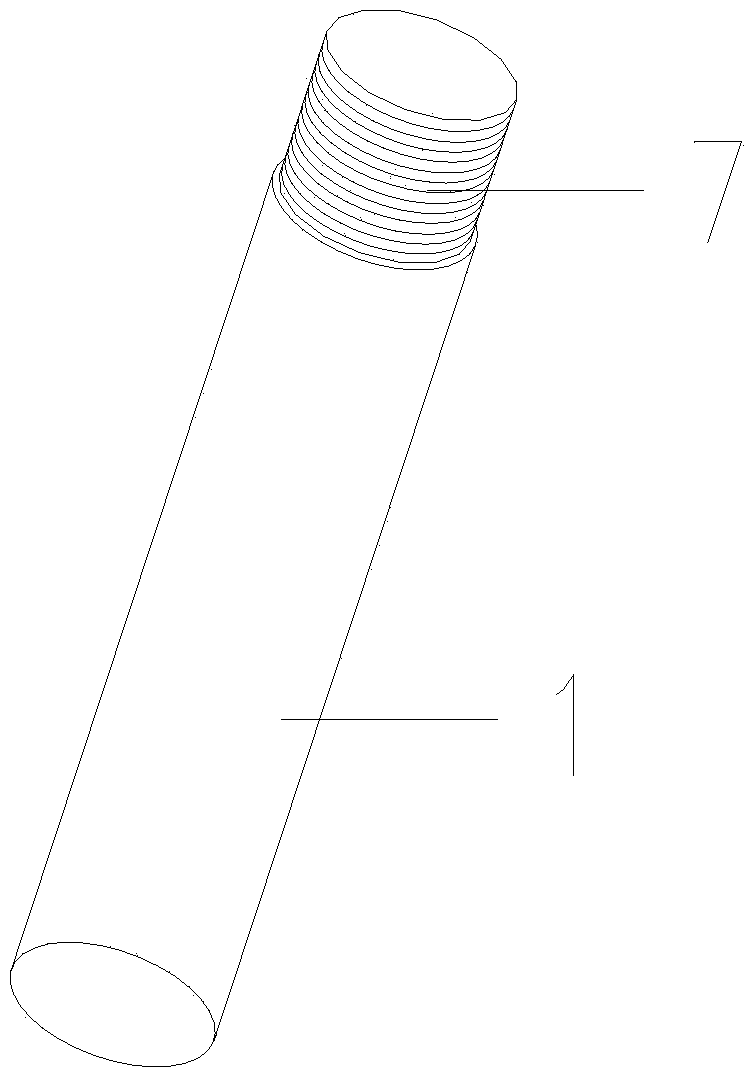

[0014] see figure 1 , figure 2 . The vacuum preloaded and consolidated vertical drainage channel used in the present invention is composed of multiple dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com