Heat accumulation water tank with new structure

A heat storage tank, a new structure technology, applied in the direction of heating devices, solar thermal devices, solar thermal power generation, etc., can solve the problem of weakening the degree of thermal stratification inside the water tank, so as to improve heat storage efficiency, improve system efficiency, and improve thermal efficiency. The effect of degree of stratification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

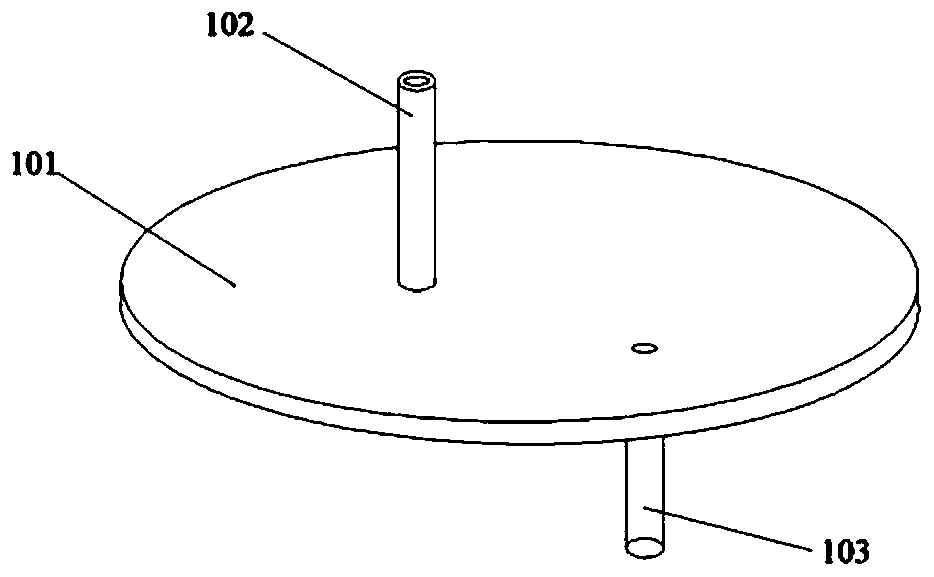

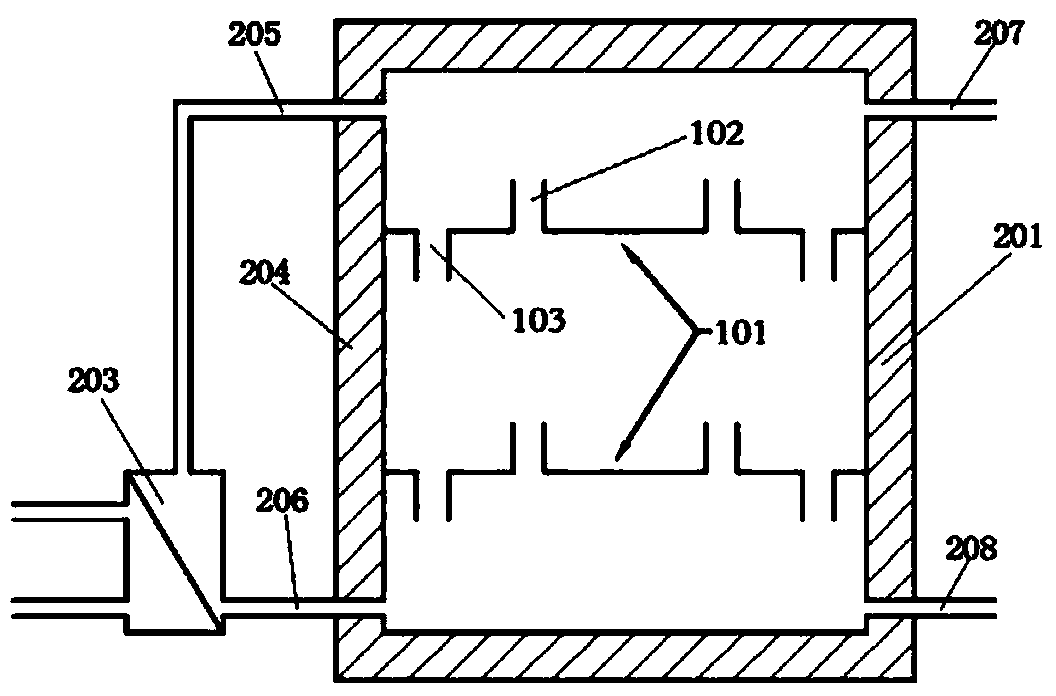

[0027] Such as figure 2 As shown, this embodiment is a heat storage tank using an external heat exchanger, wherein the inside of the heat storage tank is equipped with such figure 1 The partition plate and hot and cold fluid passage structure shown. The heat storage tank consists of a box body 201, an internal partition 101, an external heat exchanger 203, an insulation layer 204, and necessary water pipes and valves. The partition 101 is provided with a hot fluid channel 102 and a cold fluid channel 103. The box body 201 has a diameter of 0.6 meters and a height of 0.7 meters, and is made of stainless steel. Two layers of partitions 101 are arranged in the water tank, with heights of 0.23 meters and 0.46 meters respectively. Partition boards use rigid foam plastic boards with good thermal insulation properties. Two groups of fluid passages are arranged on each partition, and the number of hot and cold fluid passages is equal. The channel has a height of 5 cm and a diamet...

Embodiment 2

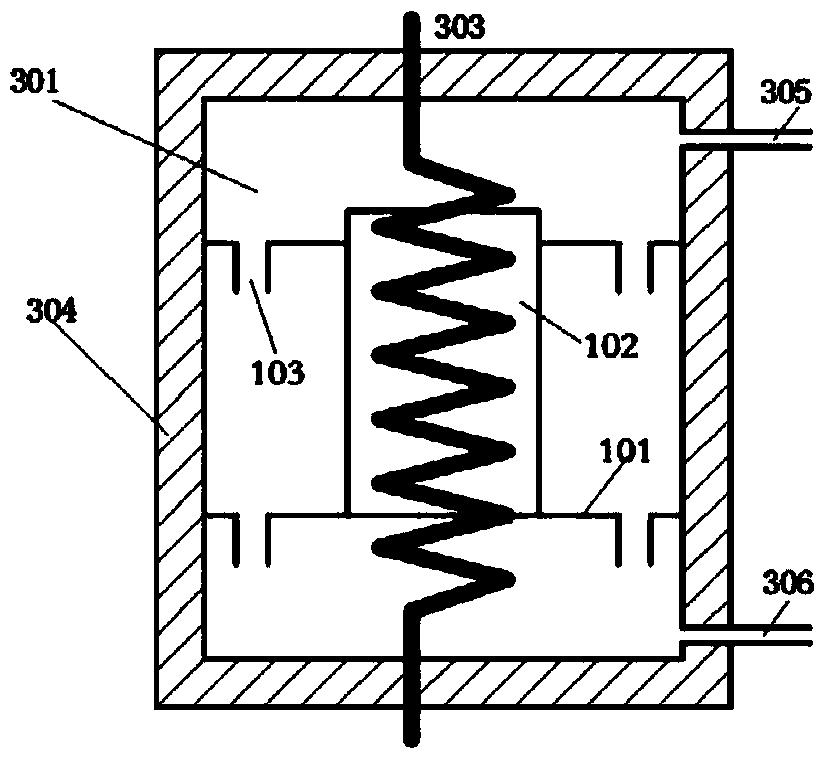

[0030] Such as image 3 As shown, this embodiment is a heat storage tank with a built-in heat exchanger, wherein the partitions and hot and cold fluid channels inside the heat storage tank are arranged as follows figure 1 shown. The heat storage tank consists of a box body 301, an internal partition 101, a built-in heat exchanger 303, an insulation layer 304, and necessary water pipes and valves. The partition 101 is provided with a hot fluid channel 102 and a cold fluid channel 103. The box body 301 has a diameter of 0.6 meters and a height of 0.7 meters, and is made of stainless steel. Two layers of partitions 101 are arranged in the water tank, with heights of 0.23 meters and 0.46 meters respectively. Partition boards use rigid foam plastic boards with good thermal insulation properties. Two cold fluid passages 103 and one hot fluid passage 102 are installed on each partition 101 . The cold fluid channel 103 has a height of 5 cm and a diameter of 2 cm, arranged symmetri...

Embodiment 3

[0033] Such as Figure 4 As shown, this embodiment is a heat storage tank using an outer cladding heat exchanger, wherein the partitions and hot and cold fluid channels inside the heat storage tank are arranged as follows figure 1 shown. The hot water storage tank is composed of a box body 401, an internal partition 101, an outer cladding heat exchanger 403, an insulation layer 404, and necessary water pipes and valves. The partition 101 is provided with a hot fluid channel 102 and a cold fluid channel. 103. The box body 401 has a diameter of 0.6 meters and a height of 0.7 meters, and is made of stainless steel. Two layers of partitions 101 are arranged in the water tank, with heights of 0.23 meters and 0.46 meters respectively. Partition boards use rigid foam plastic boards with good thermal insulation properties. The upper baffle is provided with two sets of fluid passages with equal numbers of hot and cold fluid passages. The channel has a height of 5 cm and a diameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com