Soft pack battery size testing method and system

A soft-pack battery and testing method technology, which is applied to measuring devices, instruments, and optical devices, etc., can solve the problems that the measurement results are easily affected by human factors, the probability of misoperation is high, and the efficiency is low, so as to eliminate the interference of human factors, Effects of cost reduction and productivity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

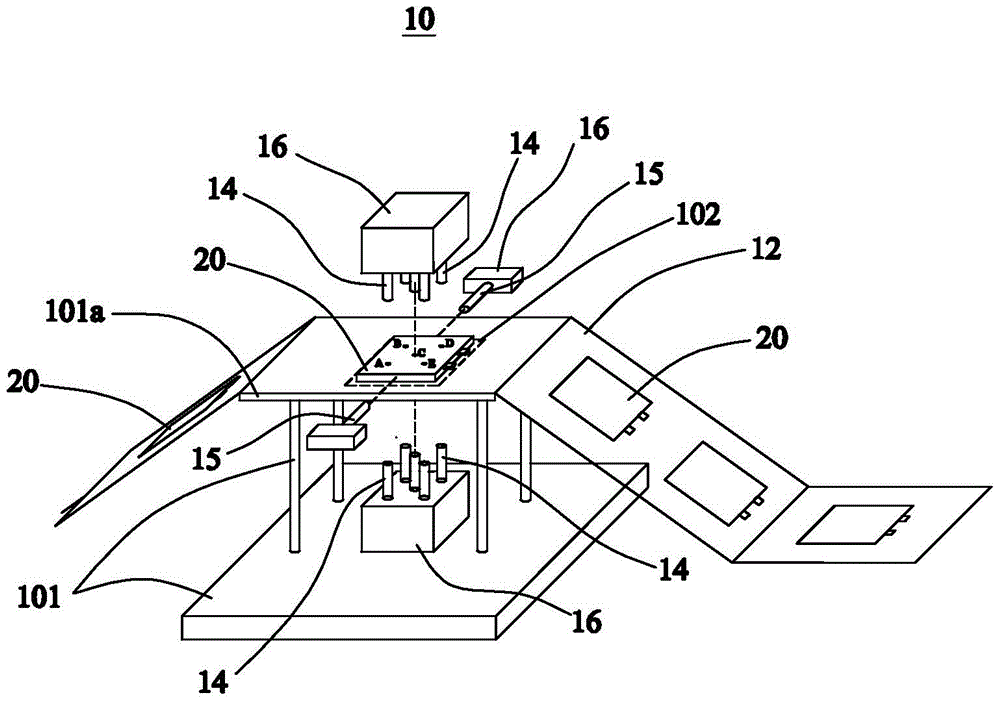

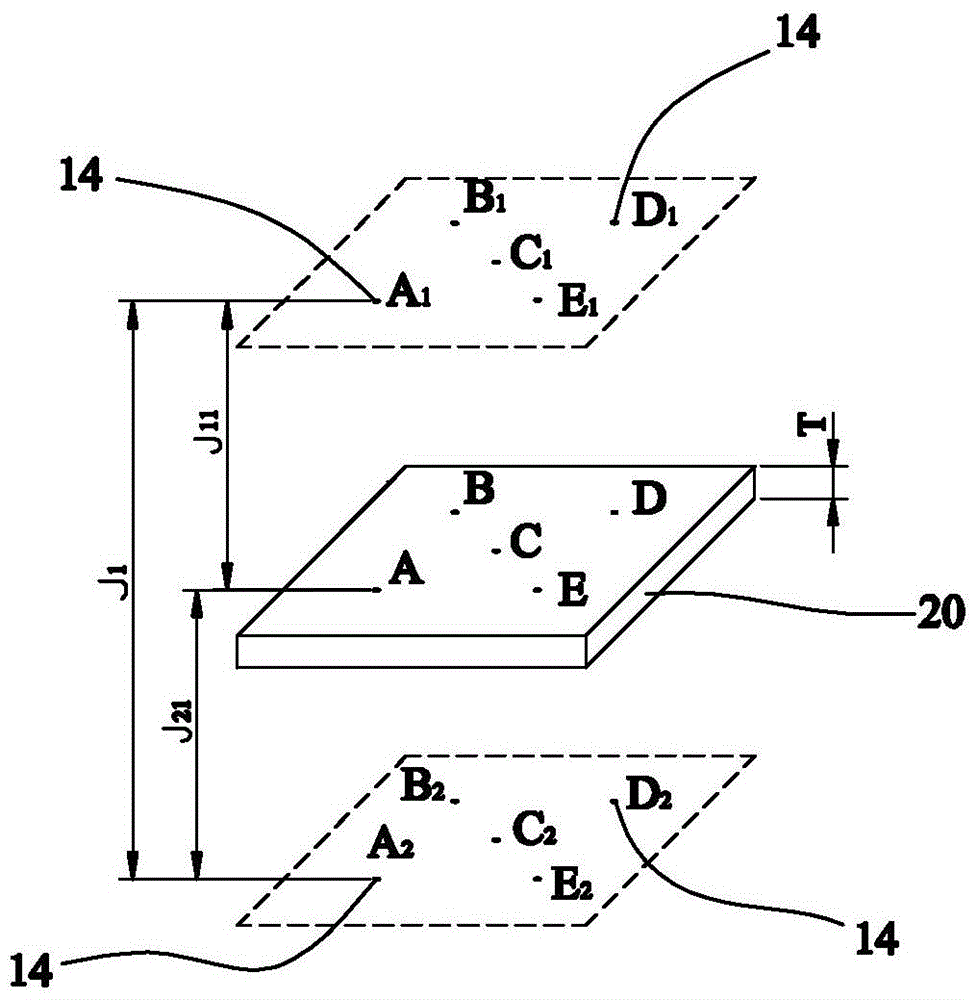

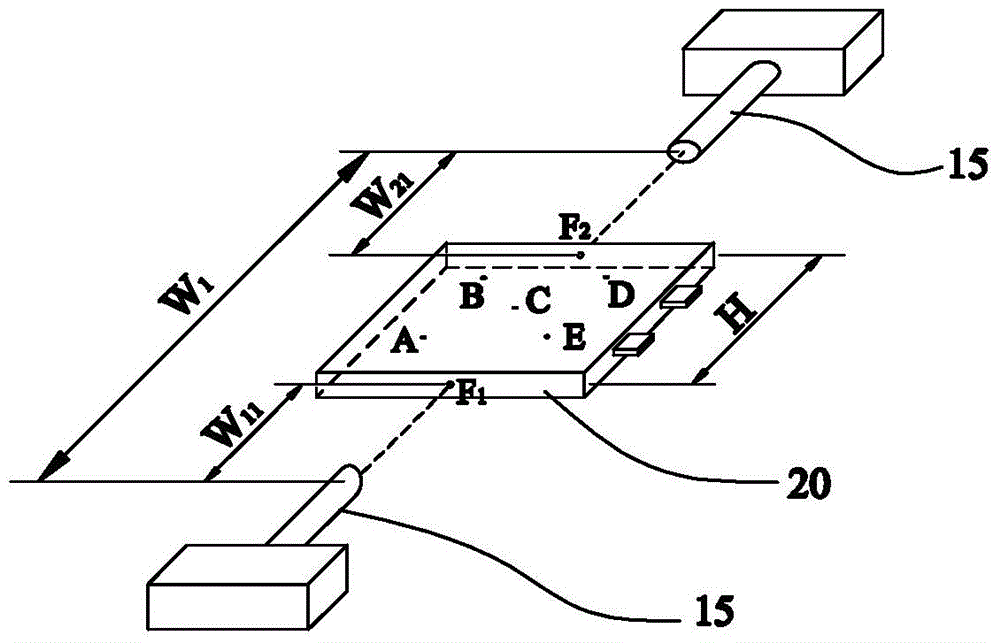

[0023] see Figure 1-Figure 4 , shows a pouch battery size testing system 10 and its components according to an embodiment of the present invention, for testing the length, width and thickness dimensions of the pouch battery 20 . Such as figure 1 As shown, the test system 10 includes a transmission element 12 for transporting the battery to be tested for testing, a plurality of pairs of longitudinal distance measuring laser heads 14, a plurality of pairs of transverse distance measuring laser heads 15 and a timing element, and a plurality of pairs of longitudinal distance measuring laser heads 14 They are respectively arranged in pairs on the upper and lower sides of the transmission element 12, and multiple pairs of lateral ranging laser heads 15 are respectively arranged in pairs on the left and right sides of the transmission element 12 (ie, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com