An electric pull rod

A lever and power technology, applied in the direction of contact operating parts, etc., can solve the problems of easy loss, cumbersome assembly operation steps, increase the workload of management personnel, etc., and achieve the effect of easy storage and carrying, standardized management, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

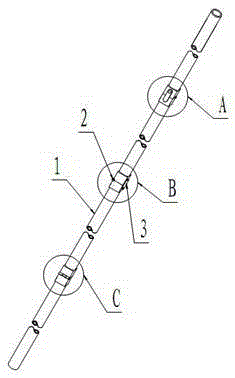

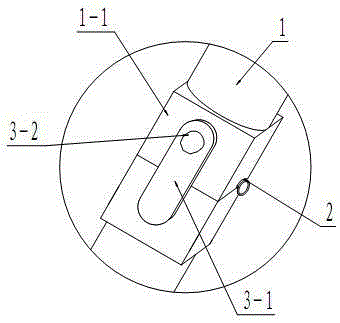

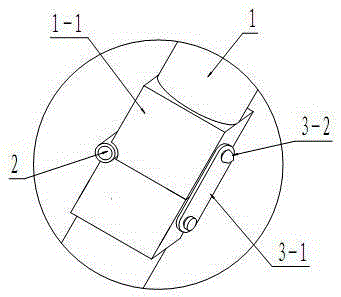

[0024] see Figure 1 ~ Figure 4 , the present invention includes a group of pull rod monomers 1, the number of said pull rod monomers is not less than three, the two ends of said pull rod monomers 1 are provided with square connecting seats 1-1, and two adjacent pull rod monomers 1 are arranged on the The hinge mechanism 2 on the square connecting seat 1-1 is connected, and the positioning locking mechanism 3 is arranged between two adjacent pull rod monomers 1-1, and the positioning locking mechanism 3 and the hinge mechanism 2 are respectively arranged on the square connecting seat 1-1 on two opposite sides; the installation orientation of the hinge mechanism 2 and the positioning lock mechanism 3 on each pull rod single square connection seat 1-1 is different, and the adjacent two groups of hinge mechanisms 2 and positioning locks The stop mechanism 3 is arranged in a criss-cross pattern.

[0025] see figure 1 , Figure 4 , the hinge mechanism 2 of the present invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com