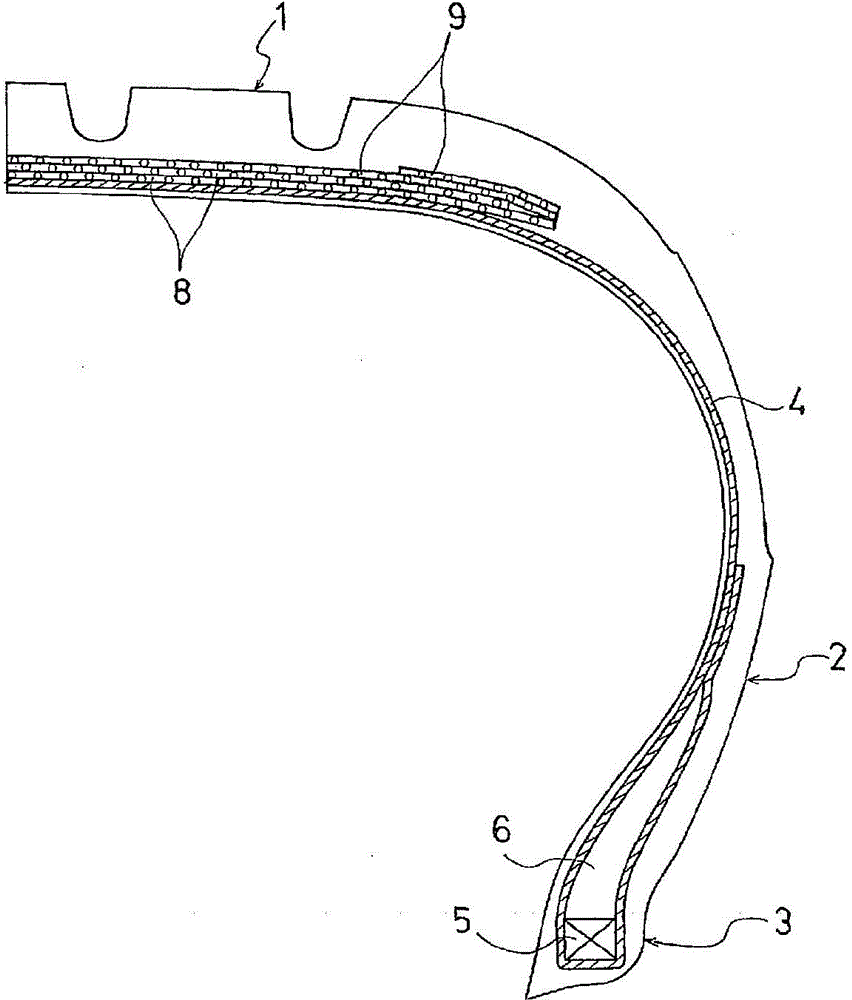

Pneumatic Radial Tire

A technology for radial tires and bead parts, applied to pneumatic tires, reinforcement layers of pneumatic tires, tire parts, etc., can solve problems such as single-strand steel wire breakage and tire durability degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

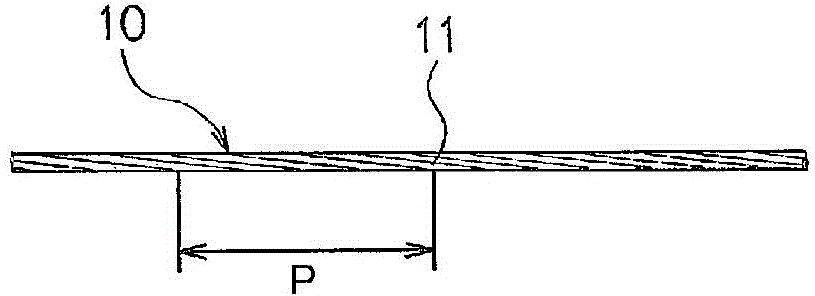

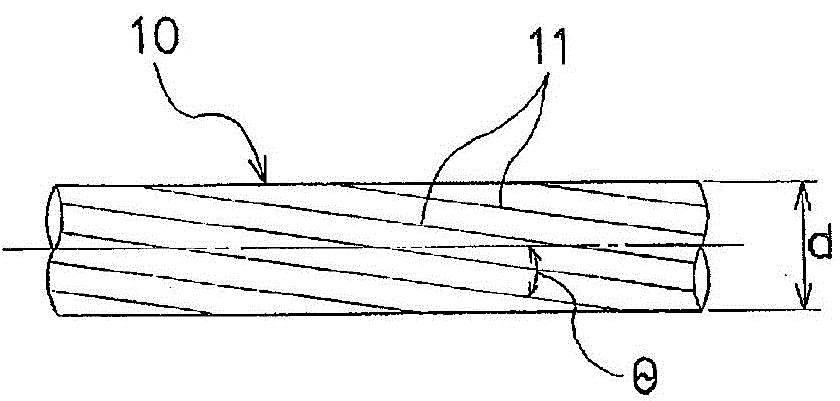

[0059] Tires of Conventional Example 1, Comparative Examples 1-7, and Examples 1-24 were produced, all of which were pneumatic radial tires, the tire size was 195 / 65R15, and a plurality of reinforcing curtains were provided on the outer peripheral side of the carcass layer of the tread portion. The belt layer is formed by burying the threads in the rubber, and the belt protection layer composed of nylon 66 fiber cords is provided on the outer peripheral side of the belt layer, and the structure of the reinforcing cords of the belt layer , wire surface torsion angle θ, bare wire diameter d, surface residual stress σ, implant density, wire gap, total cross-sectional area of wire per 50mm width, tensile stiffness per 50mm width, out-of-plane bending stiffness per 50mm width, and The twisted structure of the belt protection layer was set as shown in Tables 1 to 5. For the twisted structures of the belt protection layers in Tables 1 to 5, "dtex" is represented by "T".

[0060] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| residual stress | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com