Clutch/brake unit for an accumulation conveyor

A braking unit, storage and transportation machine technology, applied in conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of complex and expensive single-piece manufacturing, and achieve the effect of reducing the number and reliable joint.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

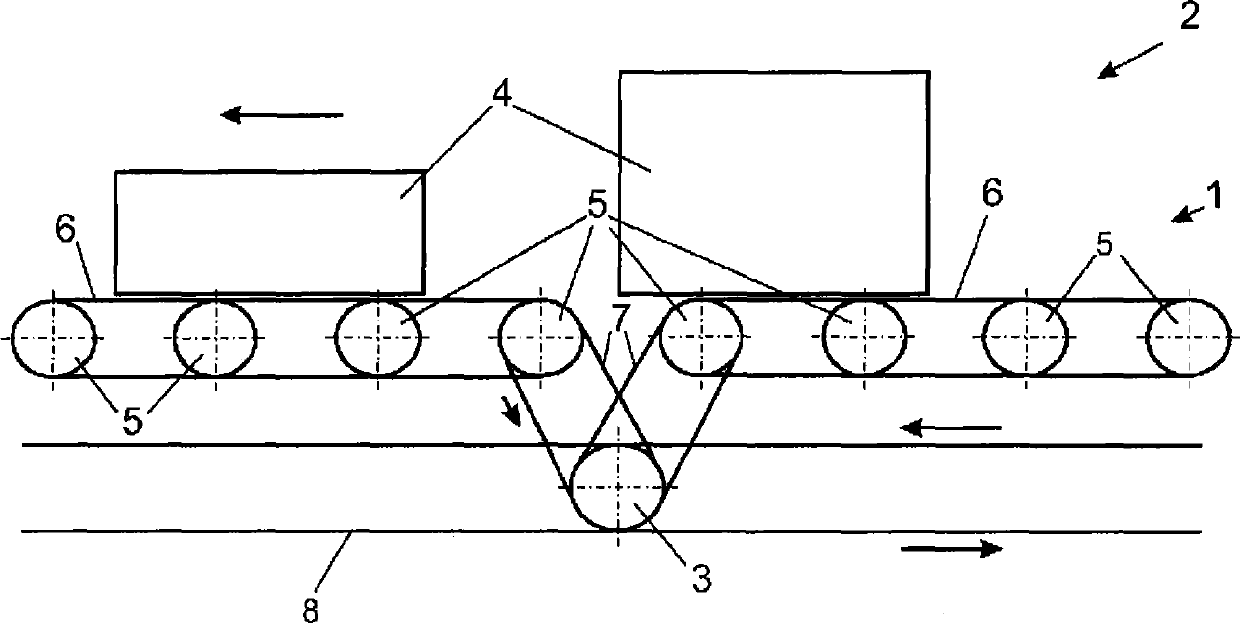

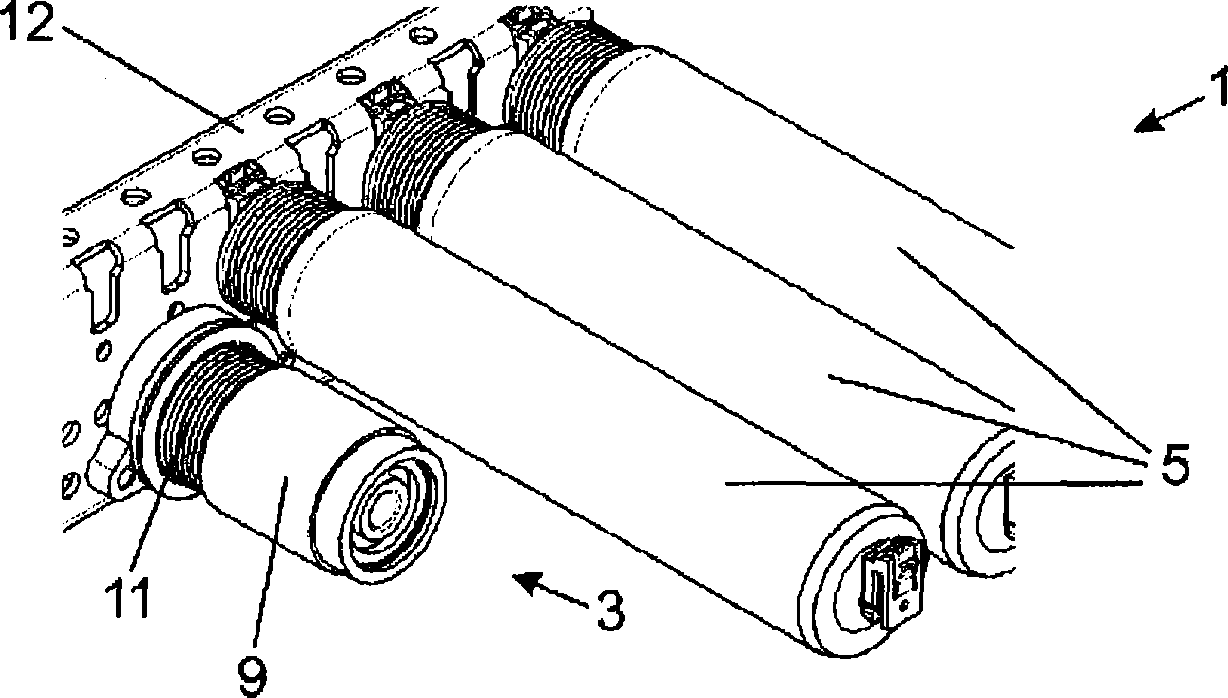

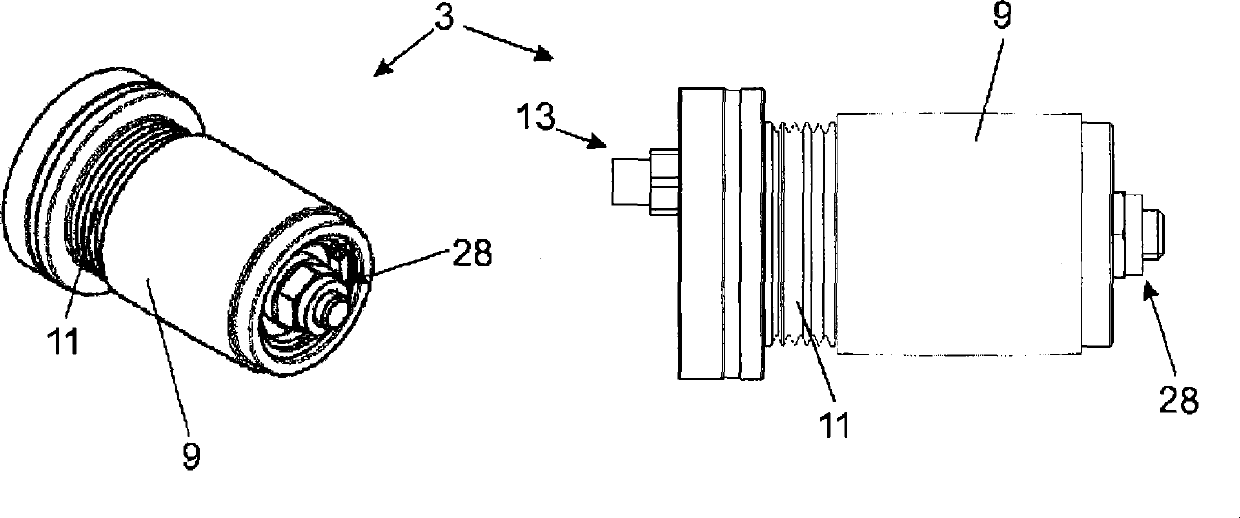

[0015] figure 1 A section of the roller table 1 of the conveyor 2 with the engaging and braking unit 3 is shown schematically. Use the storage and transportation machine 2 to transport the goods 4 (for example, from the warehouse to the entrusted place), so that the goods 4 are gathered from two conveyor belts to one. In order to prevent the items 4 from colliding, the items are accelerated and braked accordingly in certain sections of the roller conveyor 1 . roller table 1 in figure 1 The section shown in has eight rollers 5 which are connected to one another by means of continuous traction means 6 . The higher-level control unit prescribes control information: when the rollers 5 of the roller table 1 are to be braked or accelerated.

[0016] In order to drive the rollers 5 accordingly, the conveyor 2 has a coupling-brake unit 3 which is connected to the rollers 5 via two continuous traction means 7 formed by V-belts. The coupling-braking unit 3 is continuously driven by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com