Foundation for wind turbine

一种风能设备、基座的技术,应用在风能发电、机械设备、安装/支撑风力发动机的配置等方向,能够解决基座材料松动、基座材料不充分硬化、运动间隙等问题,达到均匀分布的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

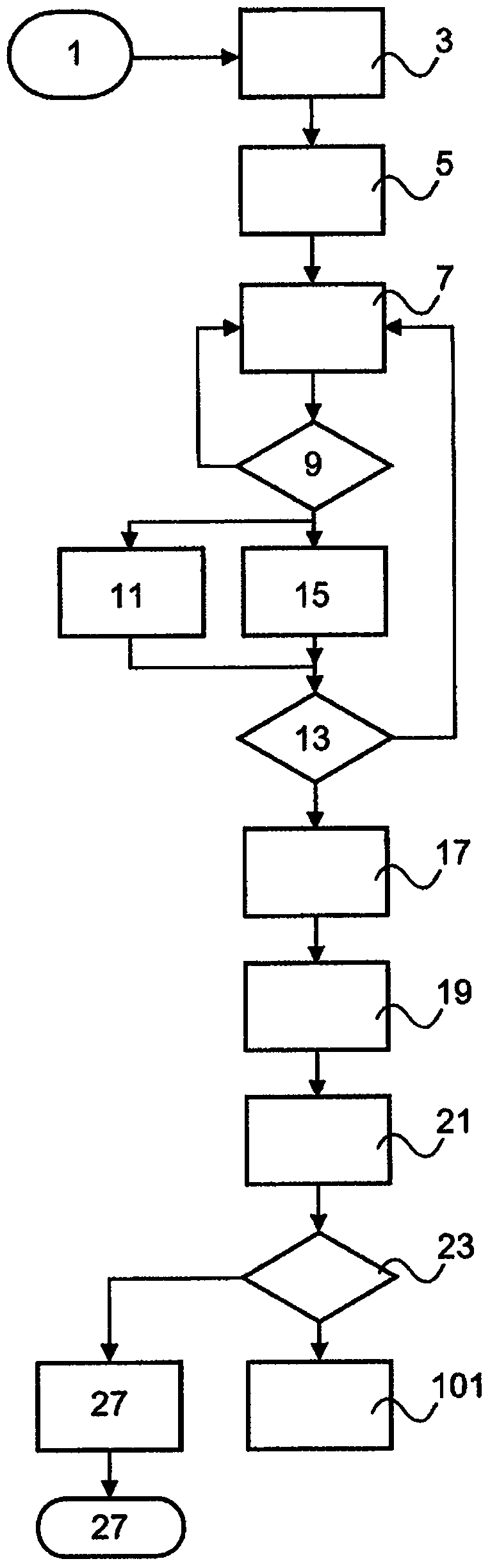

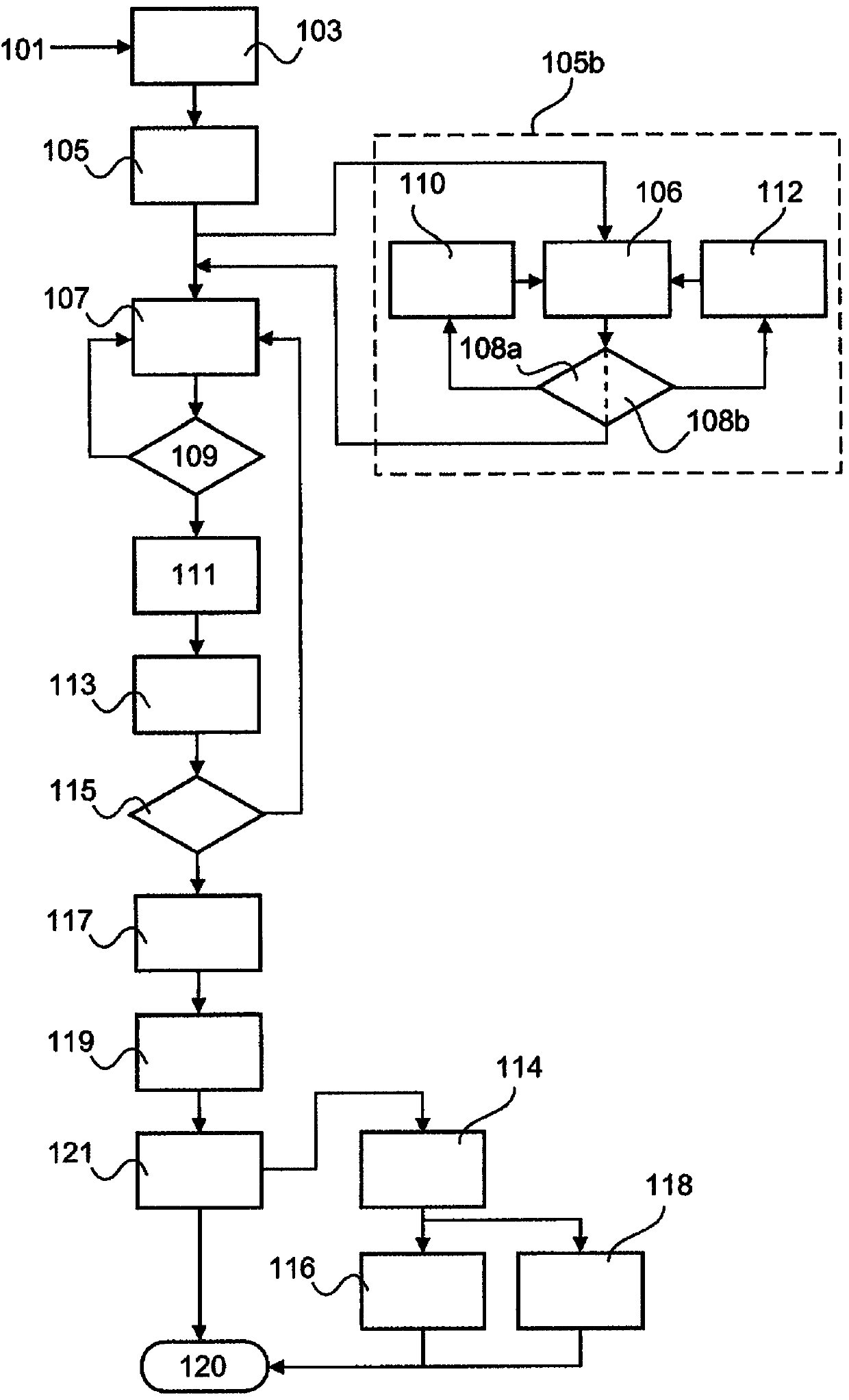

[0041] The method starts in step 1. Thereafter, the wind energy installation is first deactivated as step 3. In step 5, one or more length change sensors are optionally mounted on the tower wall or on the foundation of the wind energy installation and connected to the other parts in each case. Additionally, one or more length change sensors are calibrated in step 5. In step 7, the wind speed is determined. Optionally (not shown), the determination of the wind speed is carried out in the still active wind energy installation, and when a wind speed greater than or equal to 7.5 m / s, preferably greater than or equal to 10 m / s is measured in step 9, then Only deactivate the wind energy plant according to step 3. If a speed of less than 7.5 m / s or preferably less than 10 m / s is determined, in step 7 the determination of the wind speed is continued.

[0042] If there is a sufficiently high wind speed and the wind energy installation is disabled, then in step 11 the wind energy in...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap