An electric heating mosquito repellent

A mosquito repellent, electric heating technology, applied in fumigators, animal repellents, devices for catching or killing insects, etc., can solve the problem that mosquito repellent sheets cannot be easily taken out, inconvenient to replace, and mosquito repellent sheets can only be artificially Take out and other problems, to achieve better heating effect, easy to replace, easy to take out the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

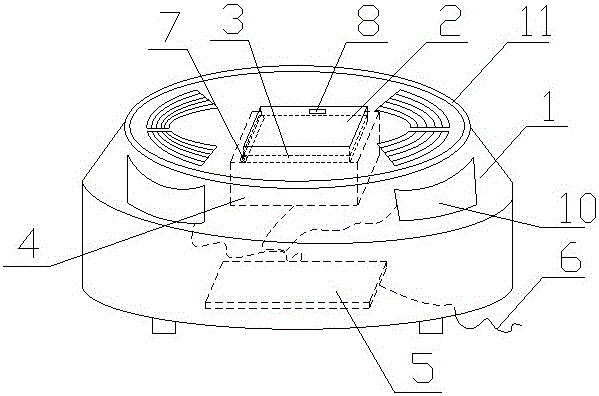

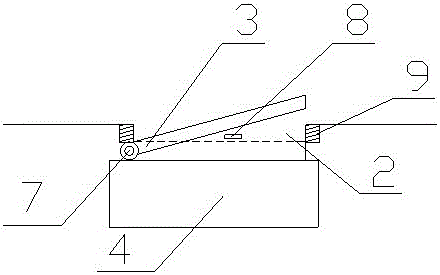

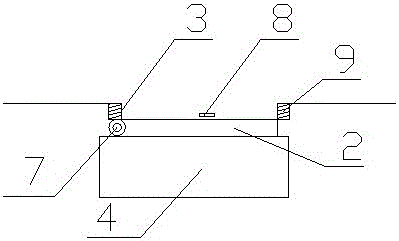

[0017] Such as figure 1 As shown, the present invention designs an electric heating mosquito repellent, which includes a housing 1, a placement groove 2 on the surface of the housing 1 for placing mosquito repellent sheets, and a circuit board 5 connected in sequence by wires 6 in the housing 1 , the heating element 4 and the heat transfer sheet 3, the circuit board 5 is used to control the heating element 4 to generate a certain temperature, so that the heat transfer sheet 3 can conduct heat. It also includes a limiting block 8 and an elastic hinge 7, the limiting block 8 is arranged on the inner wall of the placement groove 2; one end of the elastic hinge 7 is fixedly connected with the heat transfer sheet 3, and the heat transfer sheet 3 is arranged on the placement slot The bottom of the groove 2, and use the surface of the heat transfer sheet 3 as the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com