Grip type screwdriver

A screwdriver and handle technology, applied in the field of grip screwdrivers, can solve the problems of high price, low efficiency, and difficult operation of screwing, and achieve the effect of free operation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with embodiment, the present invention is further described:

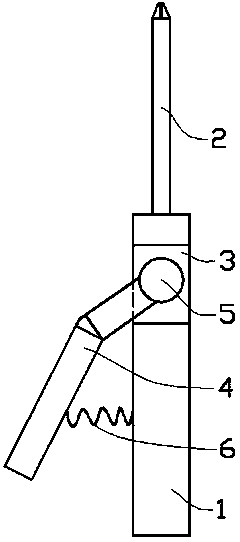

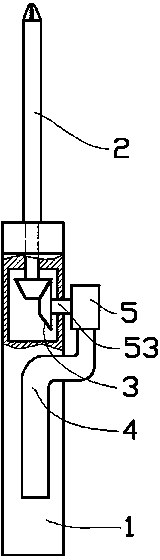

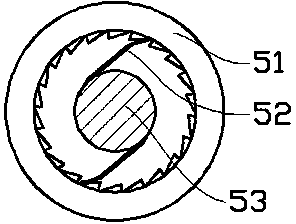

[0017] like figure 1 and figure 2 As shown in the middle embodiment, the screwdriver for this grip includes a handle 1 and an insertion rod 2; the insertion rod 2 is coaxially assembled with the handle 1, and the end of the insertion rod 2 can be used according to whether it is a flat-blade screw or a flat-blade screw. Phillips screw tightening to specific design and manufacture. The insertion rod 2 can be axially rotated relative to the handle 1 , and a transmission structure 3 is assembled inside the handle 1 , and the transmission structure 3 is connected with the insertion rod 2 in a transmission manner. The grip 1 is also equipped with a grip lever 4, and the grip lever 4 is connected to the transmission structure 3 through an anti-reversal structure 5, and the anti-reversal structure 5 can The torsion force is output horizontally, and the transmission structure 3 can output the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com