Tool for disassembling, assembling and placing disk plate of Winchester hard disk, and using method of tool

A technology of hard disk platters and platters, which is applied in the direction of manufacturing tools, hand-held tools, etc., can solve problems such as platter damage, achieve orderly placement, and improve the success rate of replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

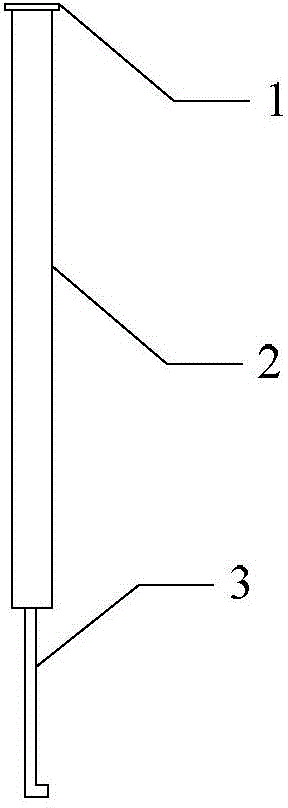

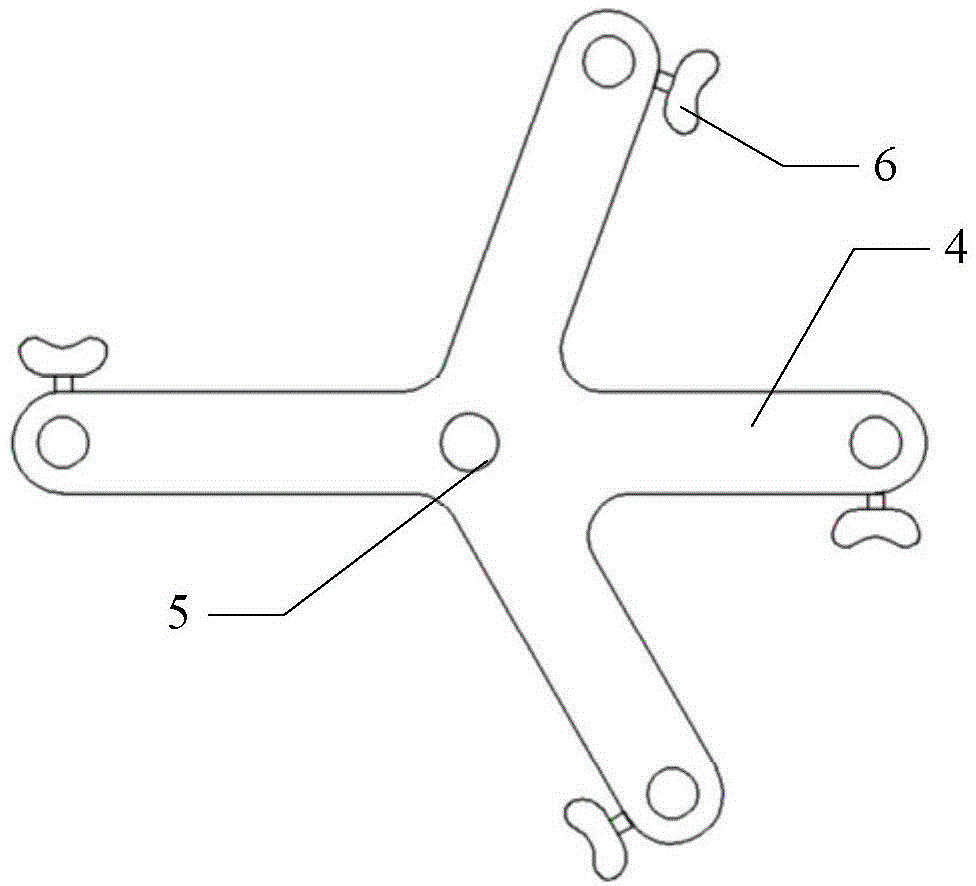

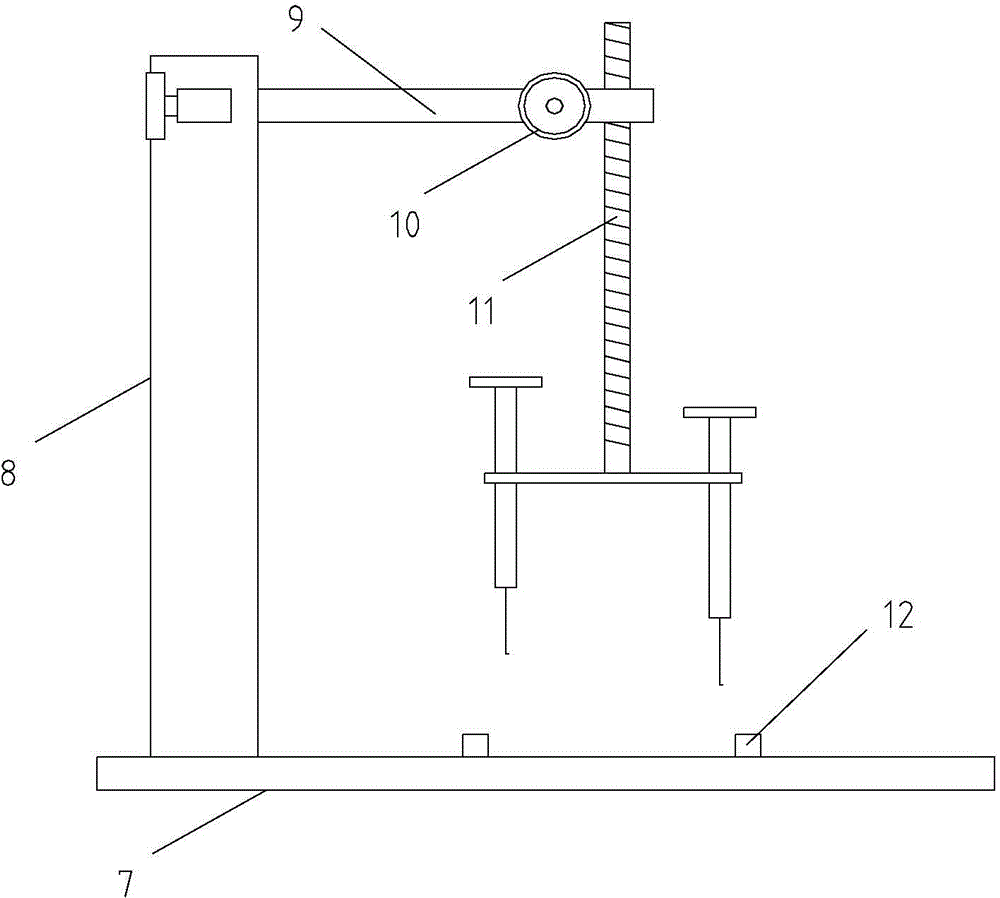

[0028] Specific implementation mode 1. Combination Figure 1-Figure 4 Describe this specific embodiment, a kind of tool described in this specific embodiment that is used for Winchester hard disk disc dismounting, installation and placement comprises M disc hanging rods, disc hanger and placing workbench, M is an integer greater than 3,

[0029] The disc hanging rod includes a circular top plate 1, a cylindrical rod 2 and a hook back rod 3, the circular top plate 1 is fixed on the upper surface of the cylindrical rod 2, and the diameter of the circular top plate 1 is larger than that of the cylinder top surface. diameter, and the circular top plate 1 is coaxial with the cylinder, the return hook rod 3 is an L-shaped structure, and the top of the return hook rod 3 is fixedly connected to the lower surface of the cylinder,

[0030] The disc hanger includes four hanger arms 4, hanger handles 5 and knob jackscrews 6, the four hanger arms 4 are cuboid structures and are located on...

specific Embodiment approach 2

[0032] Specific embodiment two, combine figure 2 This specific embodiment is described. The difference between this specific embodiment and the tool for removing, installing and placing Winchester hard disk discs described in the first specific embodiment is that each two adjacent cranes The included angles between the frame cantilever arms 4 are 60°, 120°, 110° and 70° successively.

specific Embodiment approach 3

[0033] Specific embodiment three, combine image 3 with Figure 4 This specific embodiment is described. The difference between this specific embodiment and the tool for removing, installing and placing Winchester hard disk discs described in the first specific embodiment is that the two support arms 9 The included angle is 90°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com