Plastic injection mold with rotating ejection demolding function for oblique thread workpieces

A technology of rotary ejection and injection mold, which is applied in the field of injection mold, can solve the problems such as the inability to realize the demoulding of plastic parts and the difficulty of demoulding, and achieve the effect of improving the use efficiency and service life, high demoulding efficiency and simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

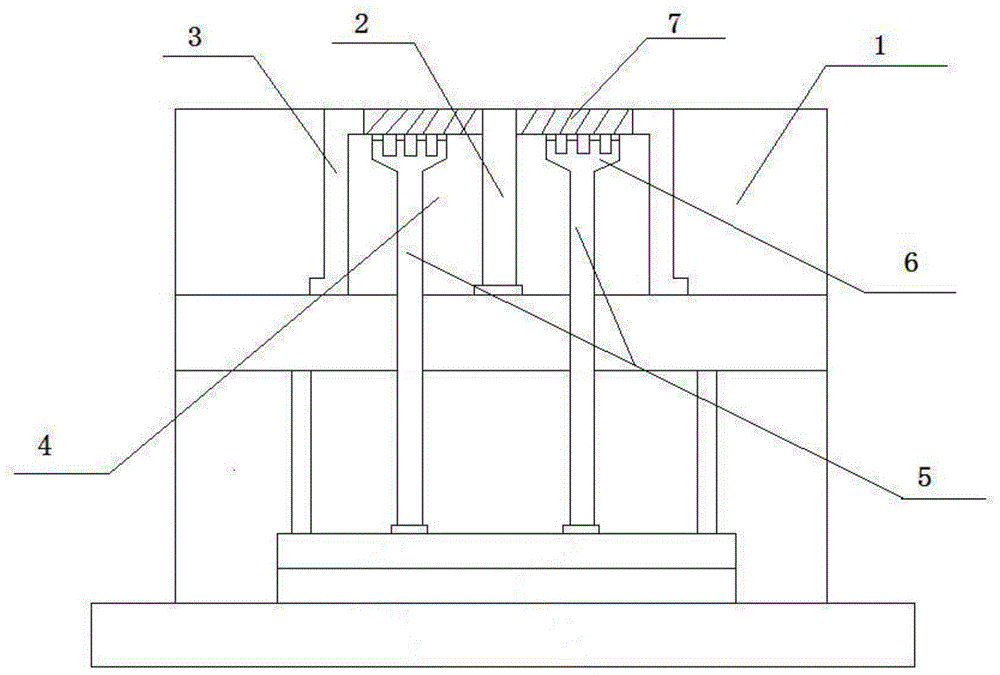

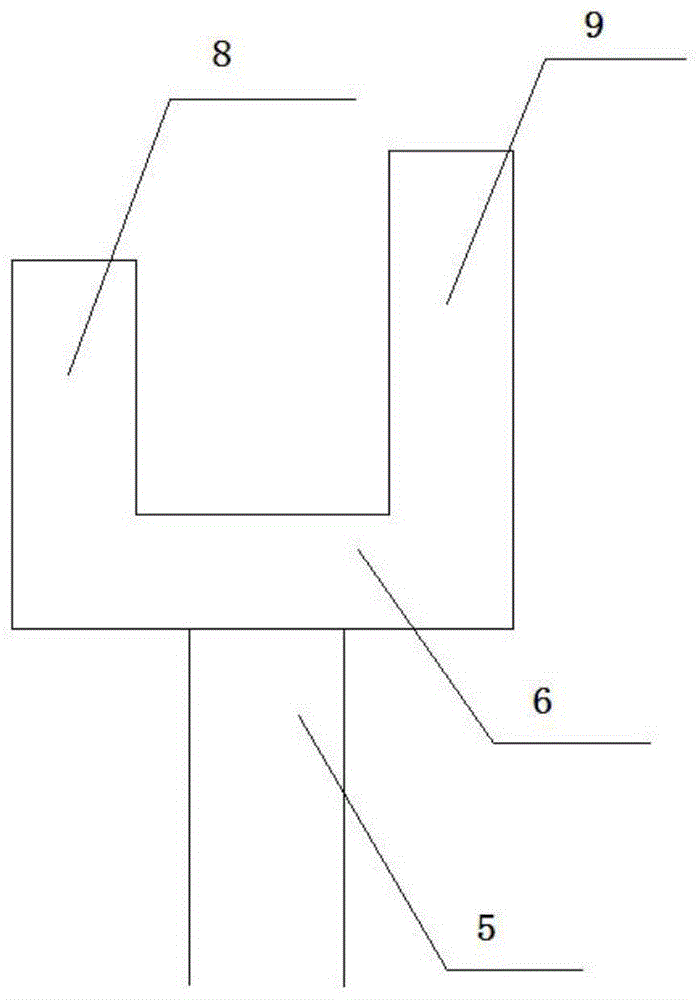

[0018] combine figure 1 , the injection mold with oblique threaded workpieces of the present invention is rotated and ejected from the mold, including a movable template 1 and a base, and the middle part of the movable template 1 away from the end of the base is provided with a cavity insert 4, and the cavity insert 4 is connected with The tooth-shaped cavity 3 is used for injection molding of the workpiece 7. The middle part of the tooth-shaped cavity 3 is provided with a core 2, and the core 2 passes through the cavity insert 4 at the same time; the base end of the movable template 1 is provided with a There is a push rod seat, the push rod seat is provided with 2 push rods 5, and the 2 push rods 5 are distributed on both sides of the core 2, the free end of the push rod 5 is provided with a push claw 6, and the push rod 5 is provided w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com