Film lifting transfer device

A transfer device and film technology, which is applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems that the two jaws cannot be lifted to the same height position, and the balance of the two jaws can not be guaranteed, so as to improve the scope of application , The effect of stable lifting and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

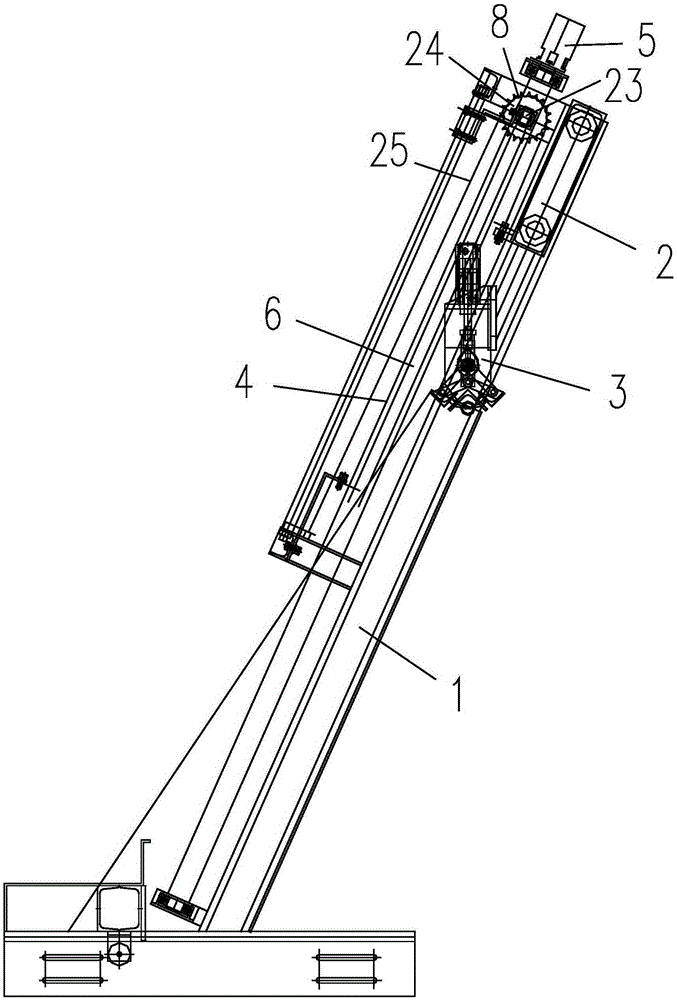

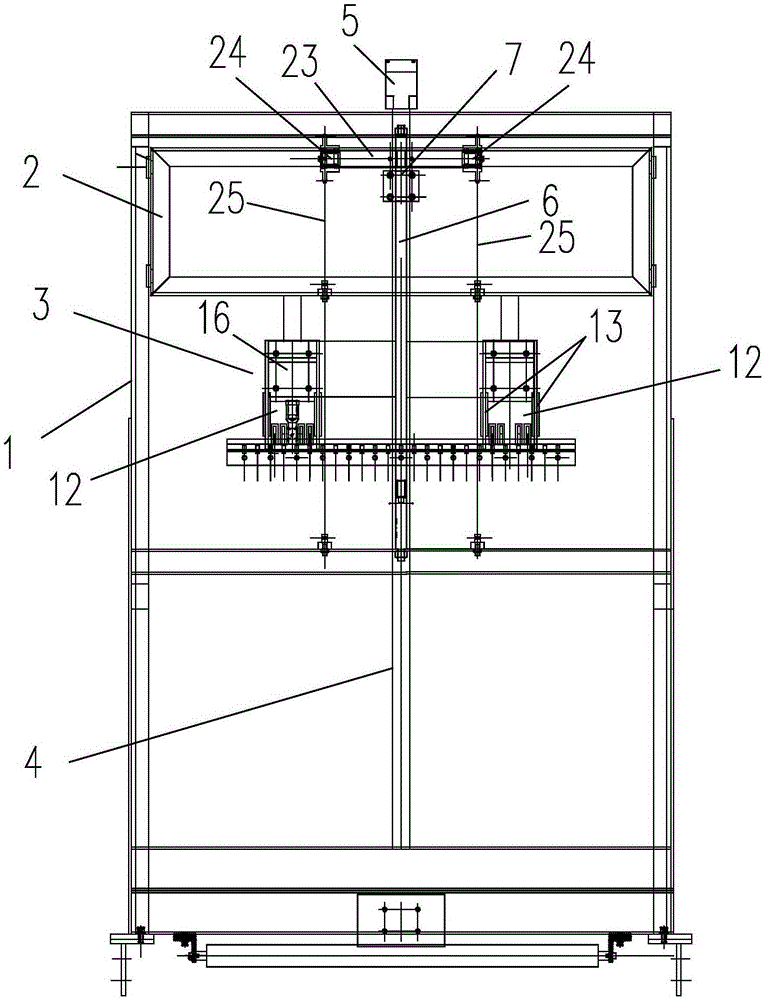

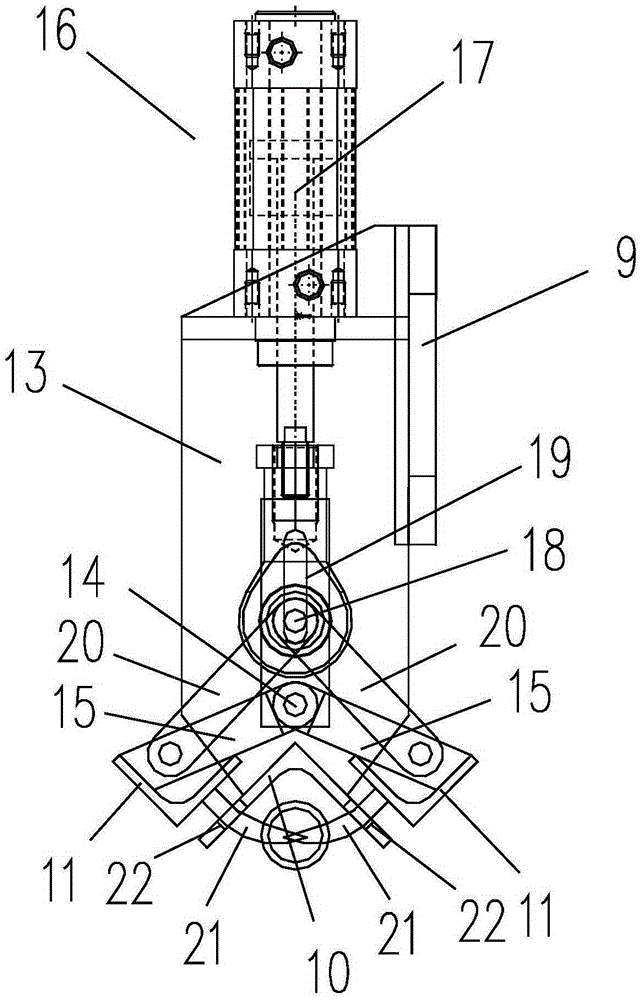

[0013] The film lifting transfer device of the present invention, such as Figures 1 to 3 As shown, it includes the lifting frame 1 tilted forward. The lifting frame 1 is equipped with a sliding table 2 that can be lifted. The two sides of the lifting frame 1 can be provided with linear guide rails or linear guide grooves. The two sides of the sliding table 2 are slidingly installed on the linear guide rail Or on the linear guide groove, because the linear guide rail or the linear guide groove is tilted forward with the lifting frame 1, so that during the lifting process of the sliding table 2, there will be a certain movement in the front and rear direction, and the film will be moved from the bottom to the rear. front top.

[0014] The grabbing device 3 is installed on the sliding table 2, and the lifting screw 4 and the servo motor 5 are also installed on the lifting frame 1. The screw 6 of the lifting screw 4 is parallel to the lifting direction of the sliding table 2, tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com