Manipulator capable of rotating quickly and accurately

A manipulator, precise technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of increasing work difficulty, winding friction on both sides, slowing down of rotation speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

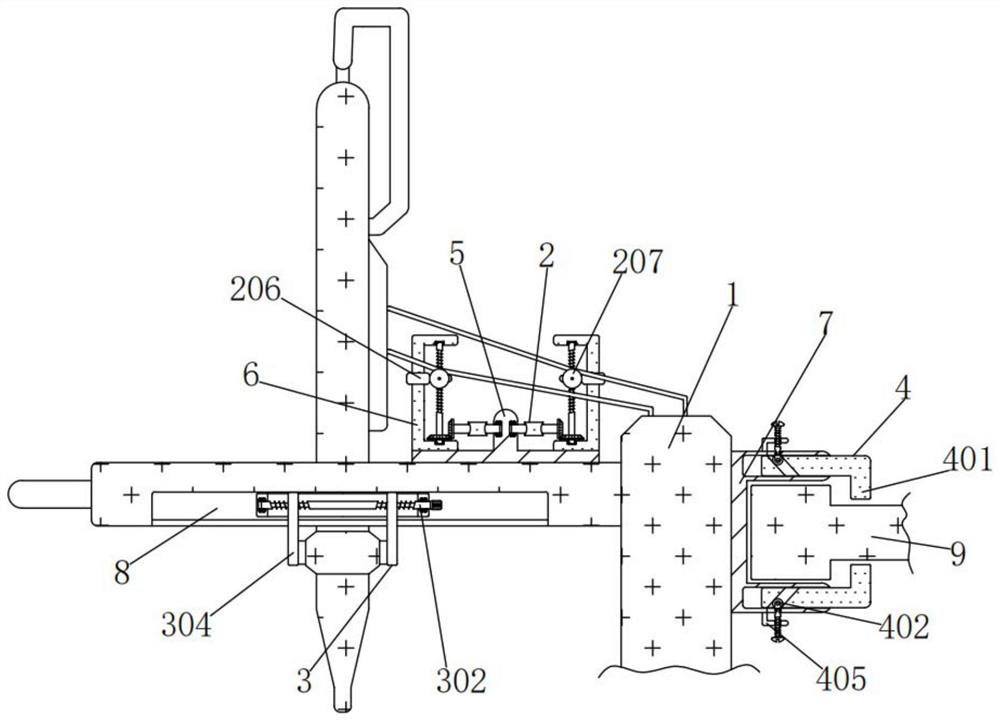

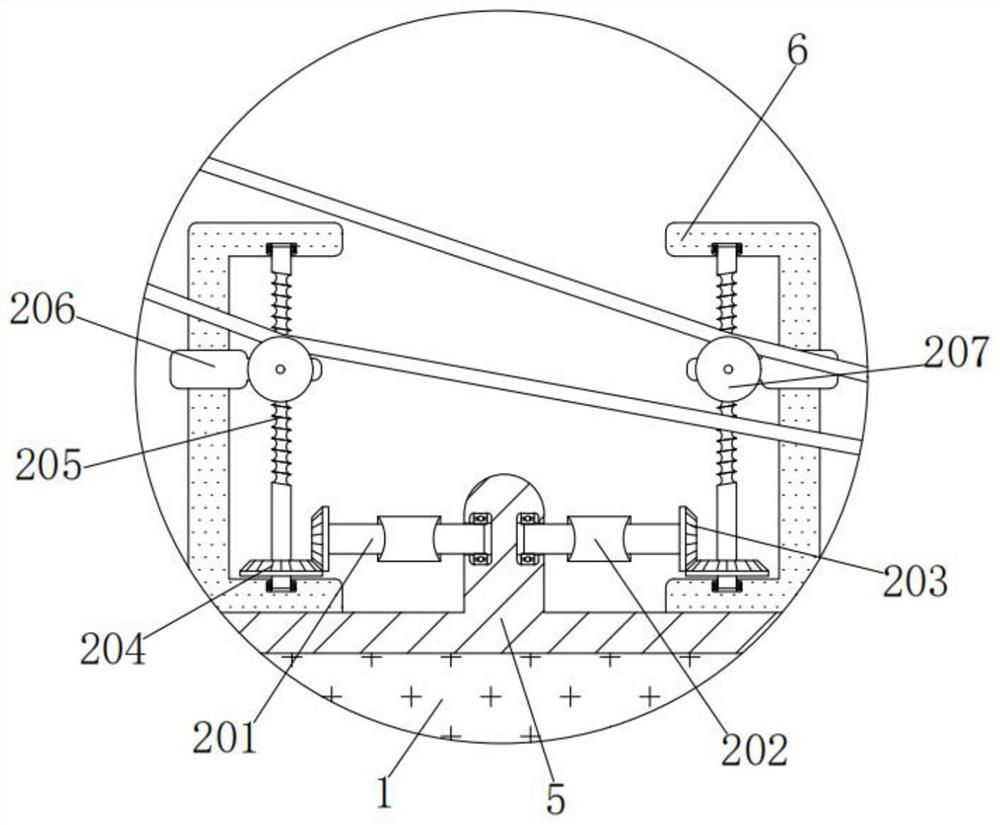

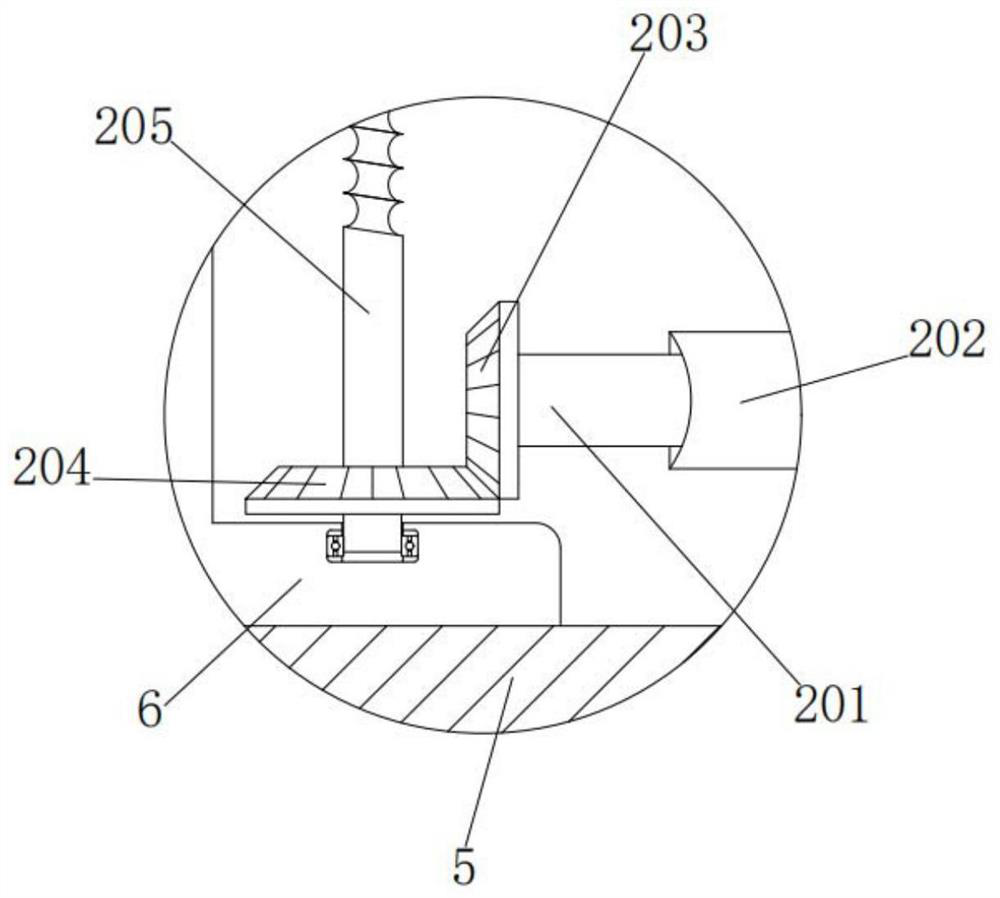

[0034] A manipulator capable of fast and precise rotation, comprising a manipulator 1, a convex plate 5 is fixedly connected to the right side of the top of the manipulator 1, square frames 6 are fixedly connected to the left and right ends of the top of the convex plate 5, and the left and right sides of the convex plate 5 are respectively Support mechanism 2 is installed, and support mechanism 2 comprises cross bar 201, rubber sleeve 202, first gear 203, second gear 204, threaded rod 205, cover plate 206 and sheave 207, and the inboard of two cross bars 201 is connected with convex respectively. The left and right sides of the plate 5 are rotated and connected, and the cross bar 201 is forced to rotate through the bearings on the left and right sides of the convex plate 5. The outer walls of the two cross bars 201 are fixedly connected to the inner walls of the rubber sleeves 202, and the rubber sleeves 202 are convenient for rotating the cross bar. 201, the outer sides of th...

Embodiment 2

[0037] As an option, see figure 1 with 4 , a manipulator that can rotate quickly and accurately, a fixing mechanism 3 is installed inside the chute 8, and the fixing mechanism 3 includes a long plate 301, a stud 302, a handle 303, a vertical plate 304 and a short plate 305, and the outer wall of the long plate 301 Sliding and clamping with the inner wall of the chute 8, the long plate 301 is forced to slide left and right through the inner wall of the chute 8, and the left and right sides of the inner wall of the long plate 301 are respectively connected to the left and right sides of the double-ended stud 302, and the double-ended stud 302 is forced to rotate through the bearings on the left and right sides of the inner wall of the long plate 301. The right end of the double-ended stud 302 is fixedly connected to the left side of the handle 303. The handle 303 is convenient to rotate the double-ended stud 302, and the double-ended stud 302 The left and right sides of the out...

Embodiment 3

[0040] As an option, see figure 1 , 5And 6, the manipulator that can rotate quickly and accurately. The right side of the manipulator 1 is fixedly connected with a concave plate 7, and a connecting mechanism 4 is installed in the grooves on the upper and lower sides of the front of the concave plate 7. The connecting mechanism 4 includes a curved plate 401 and a roller 402. , vertical plate 403, bolt 404 and bracket 405, the outer wall of the curved plate 401 is slidingly engaged with the inner wall of the groove above the front of the concave plate 7, the curved plate 401 is forced to slide left and right through the groove above the front of the concave plate 7, and the curved plate 401 The groove on the left side of the front is slidingly engaged with the outer wall of the round wheel 402. The round wheel 402 slides up and down through the front left groove of the curved plate 401 under force. The front of the round wheel 402 is connected to the inner wall of the vertical p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com