Finishing agent for improving water vapor permeability of fabric

A technology of finishing agent and water vapor, which is applied in the fields of fiber treatment, textiles and papermaking, etc., can solve the problems of complex water vapor permeability on modified fabrics, unfavorable fabric environment, and influence, so as to reduce the penetration modification process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

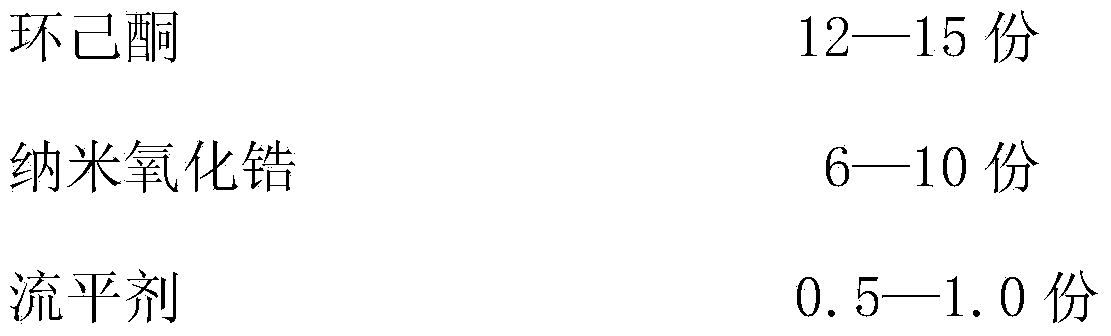

[0012] In the finishing agent for fabrics in the present embodiment, each component is calculated in parts by weight:

[0013]

[0014] According to the parts by weight of each component, the silane coupling agent, cyclohexanone, nanometer zirconia and leveling agent are dissolved in deionized water and stirred evenly to obtain the finishing agent.

Embodiment 2

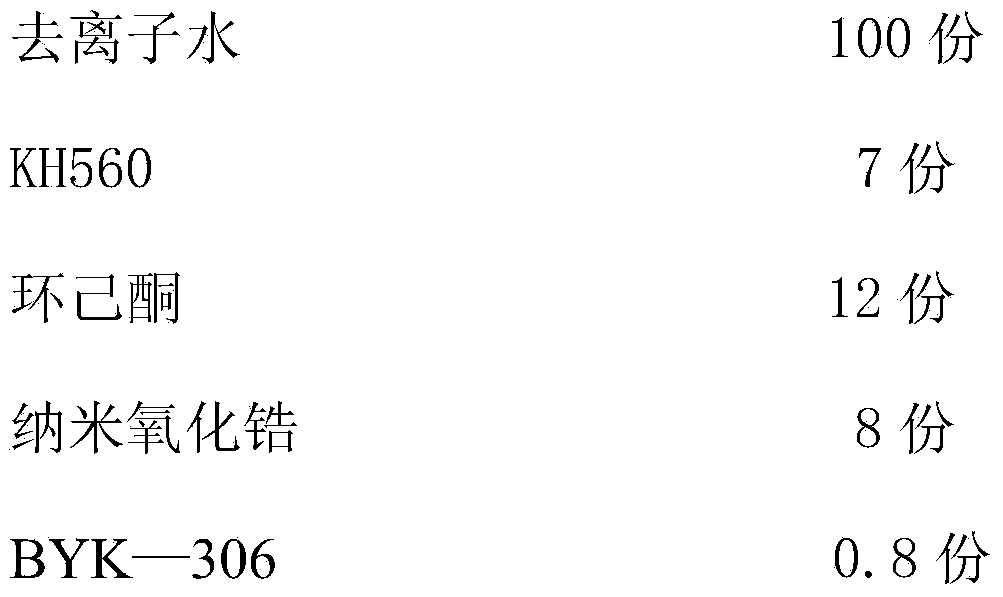

[0016] In the finishing agent for fabrics in the present embodiment, each component is calculated in parts by weight:

[0017]

[0018] According to the parts by weight of each component, the silane coupling agent, cyclohexanone, nanometer zirconia and leveling agent are dissolved in deionized water and stirred evenly to obtain the finishing agent.

[0019] Cotton fabrics are respectively modified and finished in the finishing agents of Example 1 and Example 2 (two dipping and two rolling, the ratio of material to liquid is 1:20g / ml, and the excess rolling rate is 80%, and finally the fabric is taken out and heated at 80°C. drying), the test results are shown in Table 1:

[0020] Table 1: In Examples 1 and 2, the water vapor permeability on the finished fabric

[0021]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com