A method of installing steel truss girders

An installation method and steel truss girder technology, applied in the field of steel truss girder installation, can solve the problems of not being able to meet the construction period of the Shanghai-Tongtong Railway, increasing the risk of the construction process, and the large span of the main span, so as to shorten the installation period and reduce operations Content, risk reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

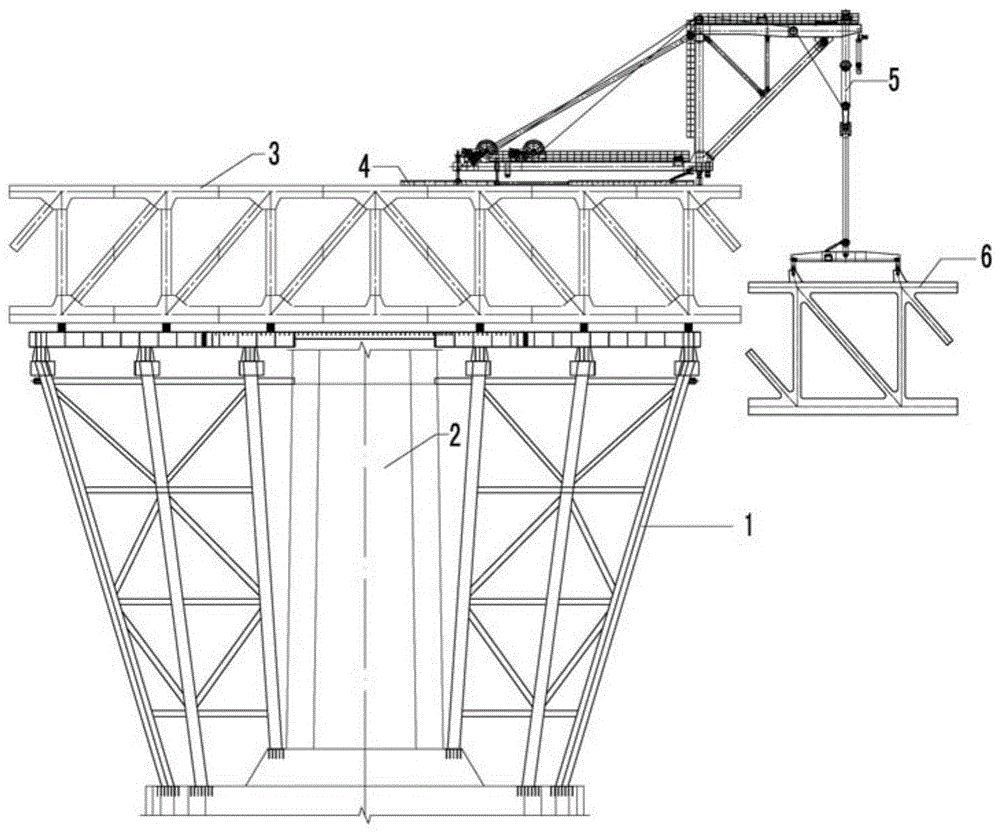

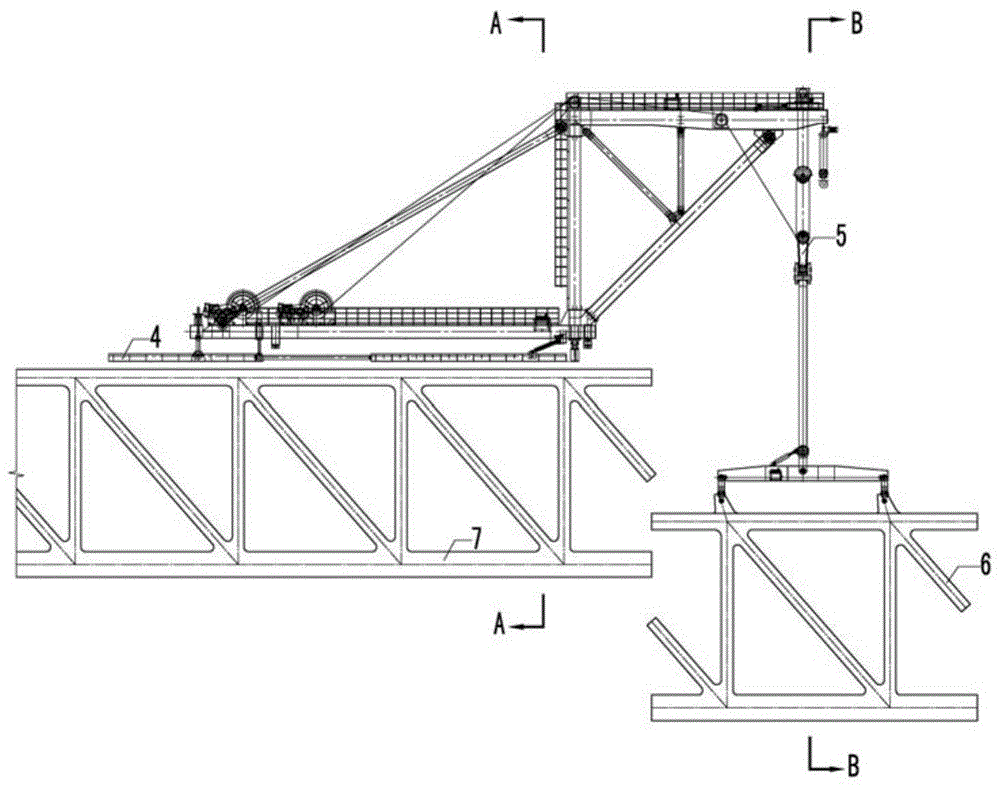

[0023] refer to figure 1 , 2 , 5, 6, the concrete installation steps of the present invention are as follows:

[0024] 1) Use the floating crane to install the brackets 1 beside the pier on both sides of the main tower pier 2, and then use the floating crane to install the internode steel beam 3 on the top of the pier;

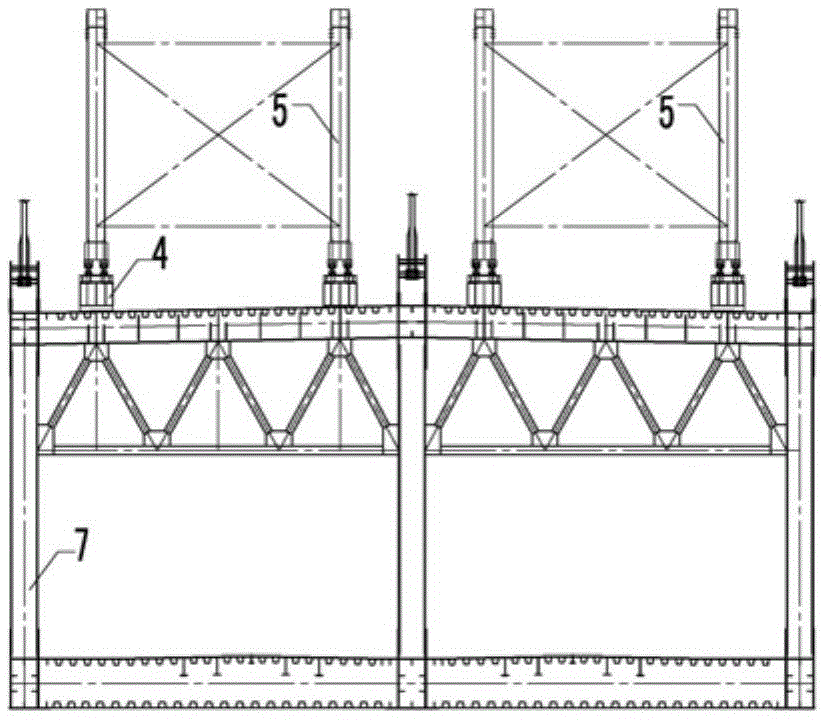

[0025] 2) On the internode steel beam 3 at the top of the pier, lay the crane walkway 4 and install the girder crane 5;

[0026] 3) Transport the truss assembly segment 6 to be packed to the bridge position by barge;

[0027] 4) Lift the combined section 6 of the truss to be packed transported to the bridge by means of the girder crane 5, align and splice with the steel girder 3 at the top of the pier, and complete the installation of the combined section 6 of the truss to be packed.

[0028] After the box truss combination section 6 is aligned and spliced, it becomes the installed box truss combination section 7, and the girder crane 5 is arranged on the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com