Partitioned step-by-step debugging method for electrical systems of fan-shaped sections of slab continuous-casting machine

A technology of slab continuous casting machine and electrical system, which is applied in the field of segmental and step-by-step debugging of the electrical system of the slab continuous casting machine segment, which can solve hidden dangers of operation safety, deterioration of the online operation environment of the segment body, and normal operation of the PLC system And hidden dangers of personal safety, etc., to ensure the quality of commissioning, facilitate the organization and implementation, and shorten the commissioning period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is further illustrated below by specific examples.

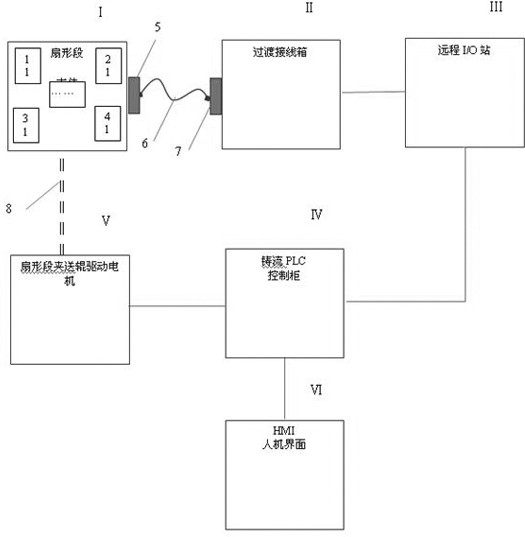

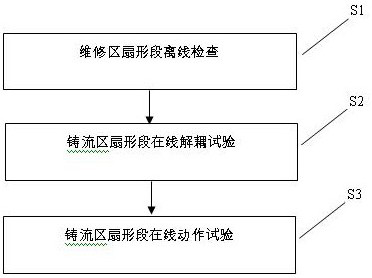

[0034] Such as figure 1 As shown, a segmental and step-by-step debugging method for the electrical system of a slab continuous casting machine segment, the slab continuous casting machine includes a ladle turret, a tundish car, a crystallizer, a segmental segment, and a conveying roller table; the segmental segment includes an arc Forming section, straightening section, horizontal section, upper and lower pinch roller drive motors of sector section, remote I / O station, casting flow PLC system for controlling casting; figure 1 As shown, 1, 2, 3, 4... in the figure are the branch junction boxes installed on the sector body and connected to the sector control components, and 5 are the general junction boxes connected to the transition junction box installed on the sector and Aviation socket, 6 is the flexible cable harness with aviation plugs at both ends connected between the sector body and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com