Construction machine

A technology for construction machinery and loaders, which is applied to cranes, mechanically driven excavators/dredgers, earth movers/shovels, etc., can solve problems such as accelerated hose damage and hydraulic system failures, to avoid impact, The effect of reducing the number of failures and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

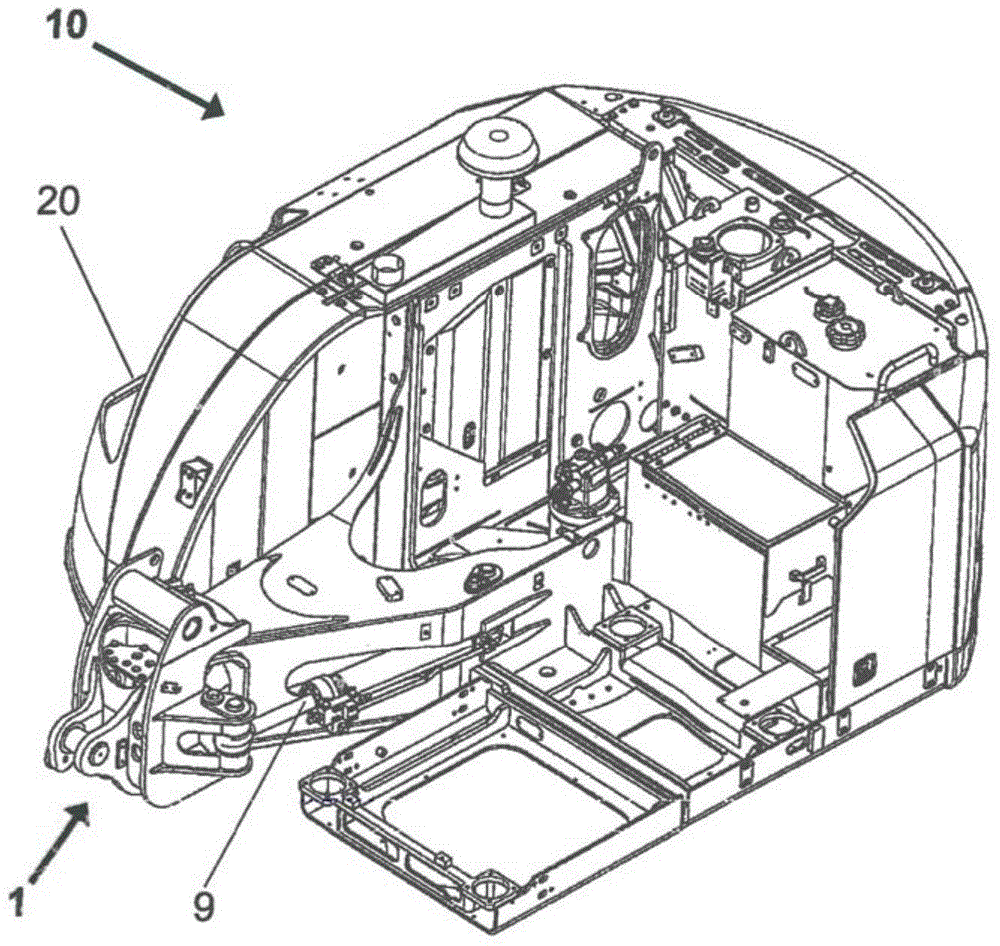

[0032] figure 1The structure shown in represents the superstructure 10 of the construction machine according to the invention. For example, the construction machine may be a mobile excavator or a conveyor designed like a mobile excavator, comprising a chassis (not shown) supporting the travel gears and a superstructure 10 pivotally connected to the chassis.

[0033] For this purpose, for construction machines of this class, the chassis carries a traction gear, which can be designed, for example, as a simple wheeled traction gear or as a tracked traction gear. Here, the type of travel gear used is not relevant for the invention.

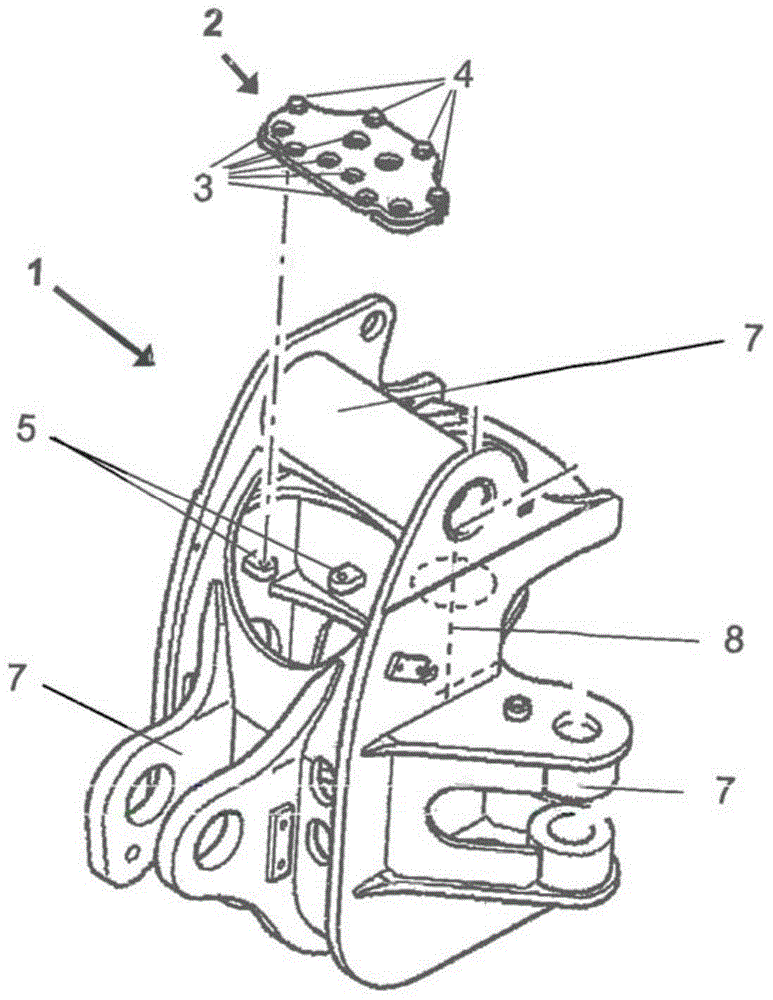

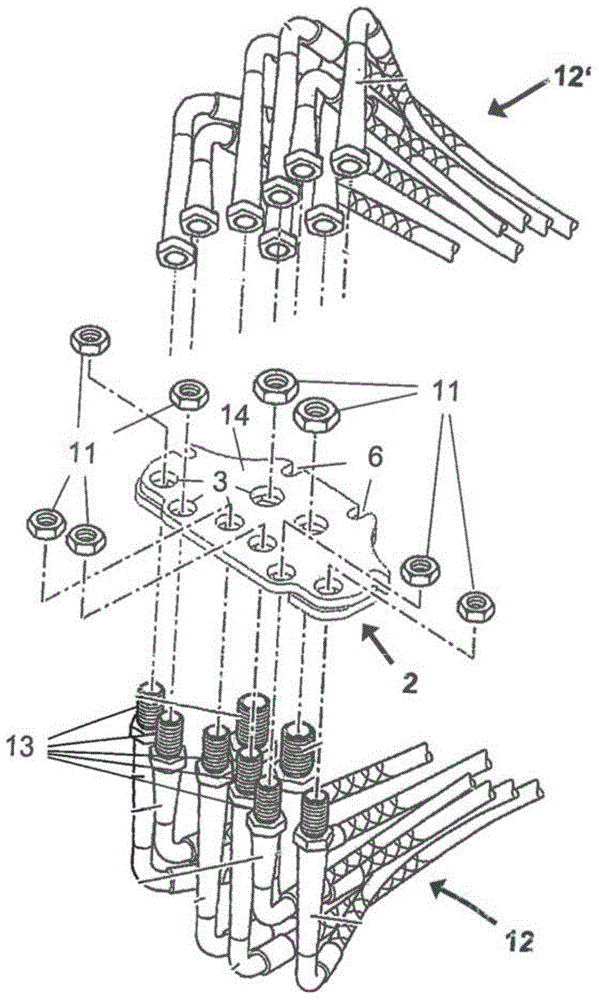

[0034] The superstructure 10 mainly comprises a rotating platform, on the upper side and the side walls of which are arranged on the right side in the direction of travel, all modules of the superstructure 10 are arranged on standard interfaces. In the front region of the superstructure 10 there is a pivot bearing 1 , in this case for receiving a pi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap