An anti-loose anti-skid channel and its installation and connection device

A connecting device and channel technology, applied in the direction of overhead lines, buildings, building structures, etc., can solve the problems of lack of reliable locking, difficult installation and positioning, limited stability and reliability, etc., and achieve stable and reliable installation and connection. Stable, reliable and economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

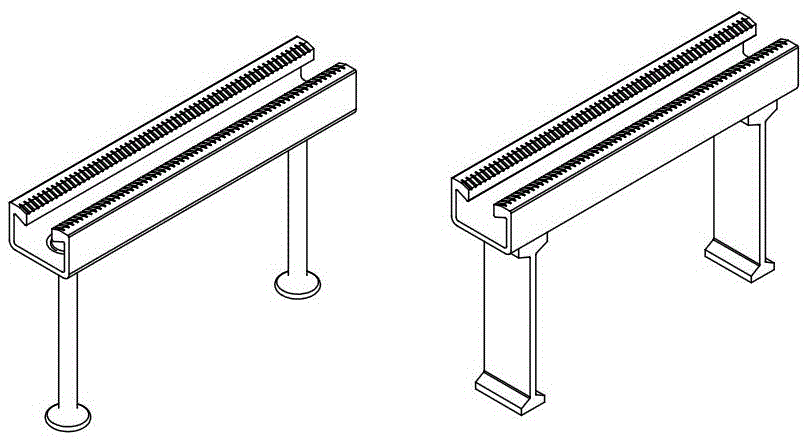

[0025] Such as Figure 4 , the channel is pre-welded on the steel structure or embedded in the concrete pouring surface, and the channel opening and installation face outward;

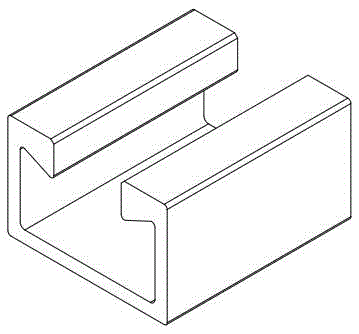

[0026] The bottom of the concrete pre-embedded channel can have such Figure 1-2 Forged anchor bolts or welded anchor feet or integral cast anchor feet to enhance the combination with concrete;

[0027] Put the head 2 of the bolt (2) into the T-shaped slot of the channel (1), move it to the required position, and rotate the bolt (2) 90 degrees around its own axis;

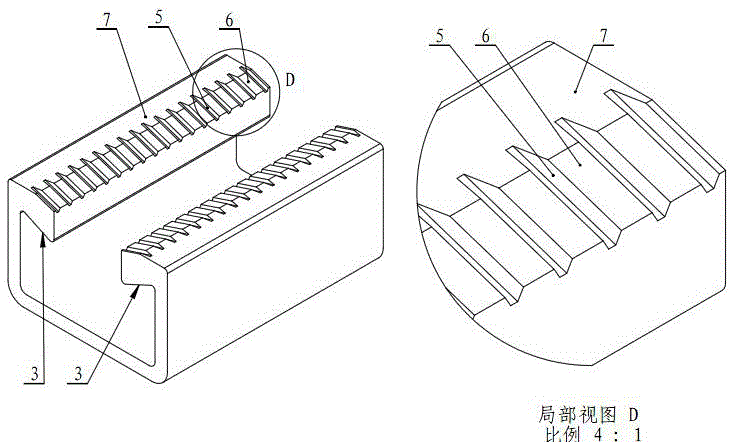

[0028] Insert the pad (3) into the shaft of the bolt (2), hook 1 and the tooth surface 4 to the side of the channel, the tooth surface 4 is opposite to the tooth surface 5 of the channel (1), and the clamp hook 1 is located in the channel (1) Inside the opening;

[0029] Press the pad (3) to the bottom so that the clamp hook 1 hooks the bottom of the head 2 of the bolt 2, and use the elastic force of the pad (3) to make the head 2 of the...

Embodiment 2

[0032] Such as Figure 4 , the channel is pre-welded on the steel structure or embedded in the concrete pouring surface, and the channel opening and installation face outward;

[0033] The bottom of the concrete pre-embedded channel can have such Figure 1-2 Forged anchor bolts or welded anchor feet or integral cast anchor feet to enhance the combination with concrete;

[0034] Cover the rod with the pad (3), the head 2 of the bolt (2) with the mounting workpiece (4) and the fastening nut, and the clip hook 1 of the pad (3) (tooth surface 4-way groove On the side of the channel, the tooth surface 4 is opposite to the tooth surface 5 of the channel (1), and the clip hook 1 is located in the opening of the channel (1)) together into the T-shaped slot of the channel (1), and moved to the required position , rotate the bolt (2) 90 degrees around its own axis;

[0035] Screw in the fastening nut, press the pad (3) to the bottom, make the clamp hook 1 hook the bottom of the head ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com