Patents

Literature

46results about How to "Reliable installation and connection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pipeline connecting pipe fitting

InactiveCN103775761AReduce assembly torqueImprove joint sealing performanceJoints with sealing surfacesThin walledEngineering

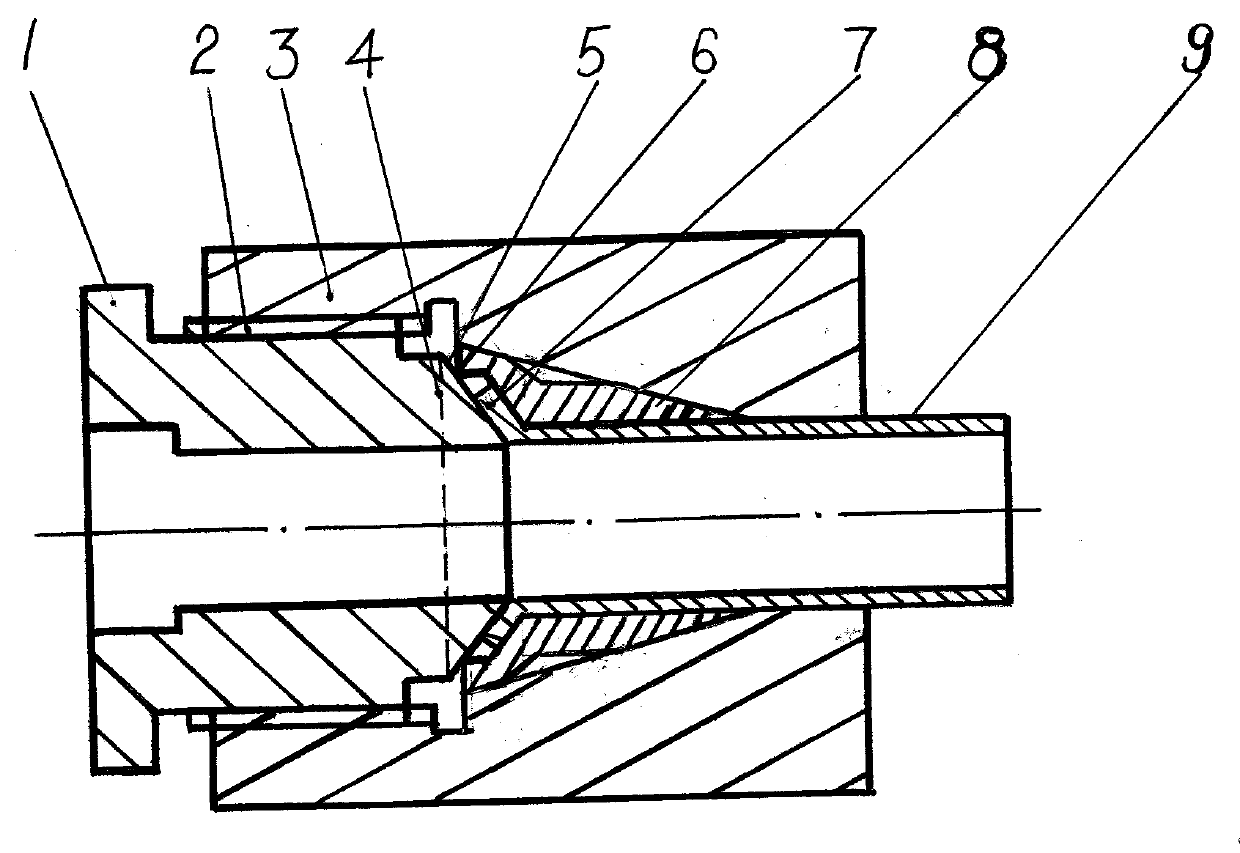

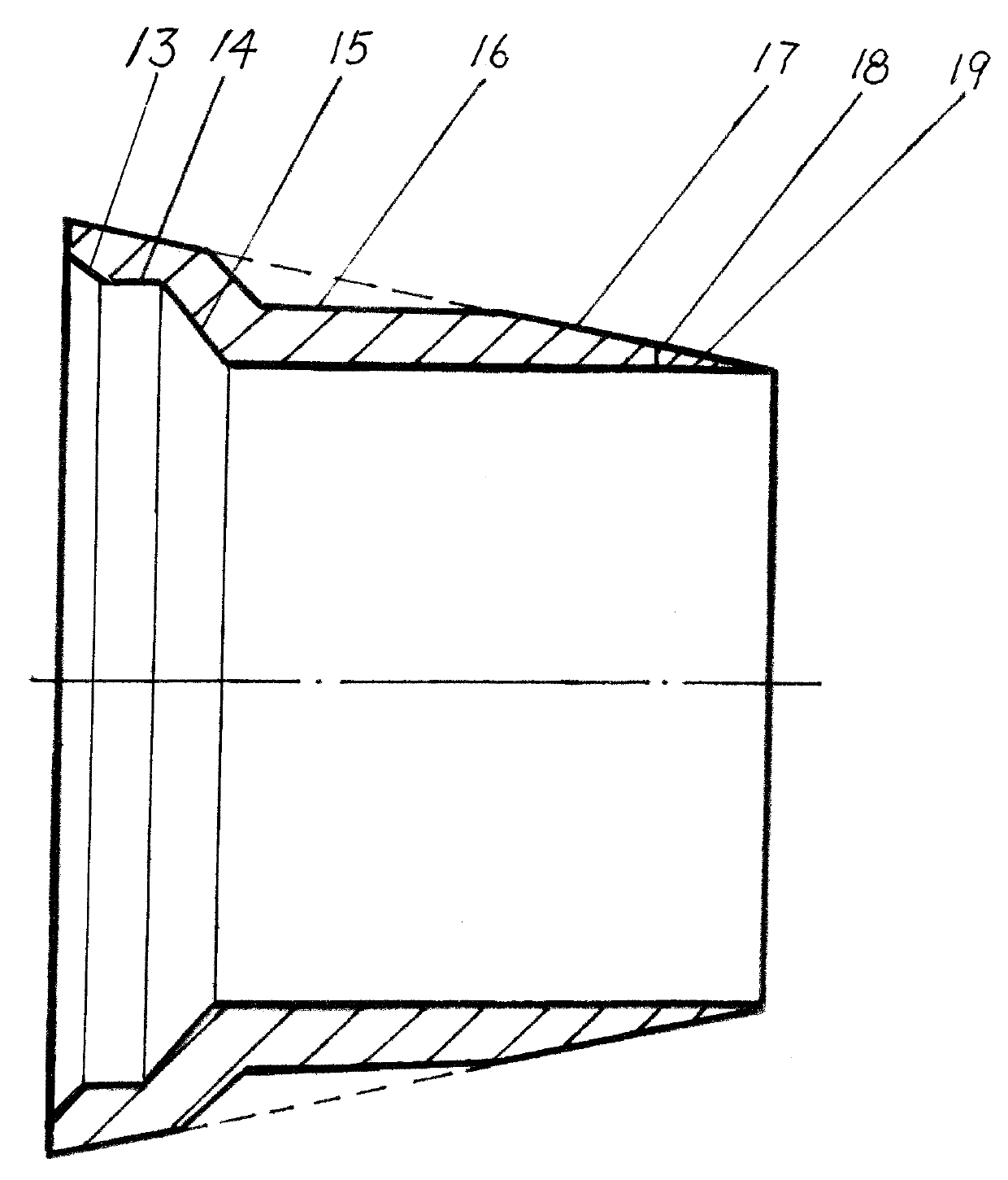

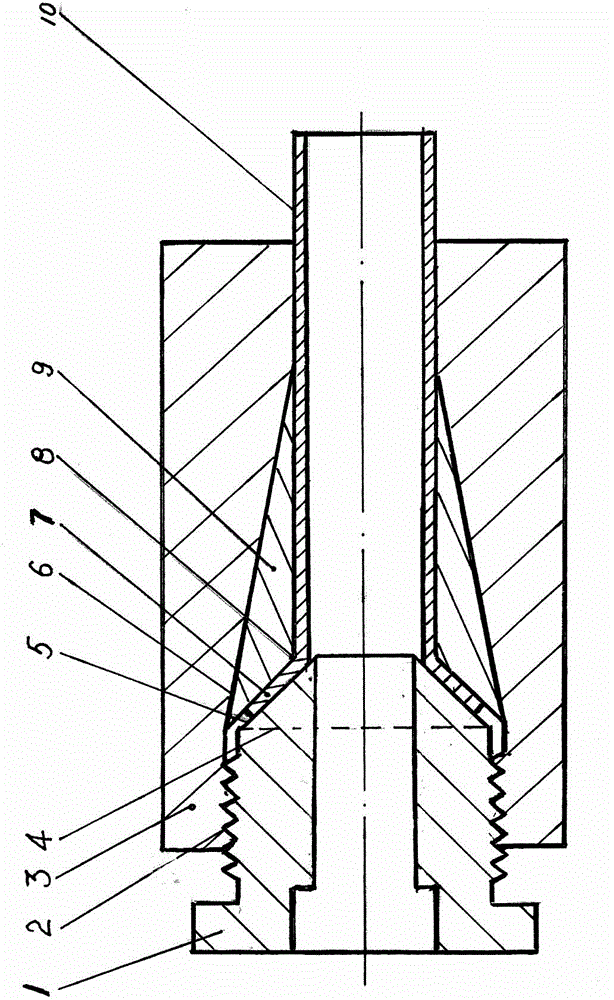

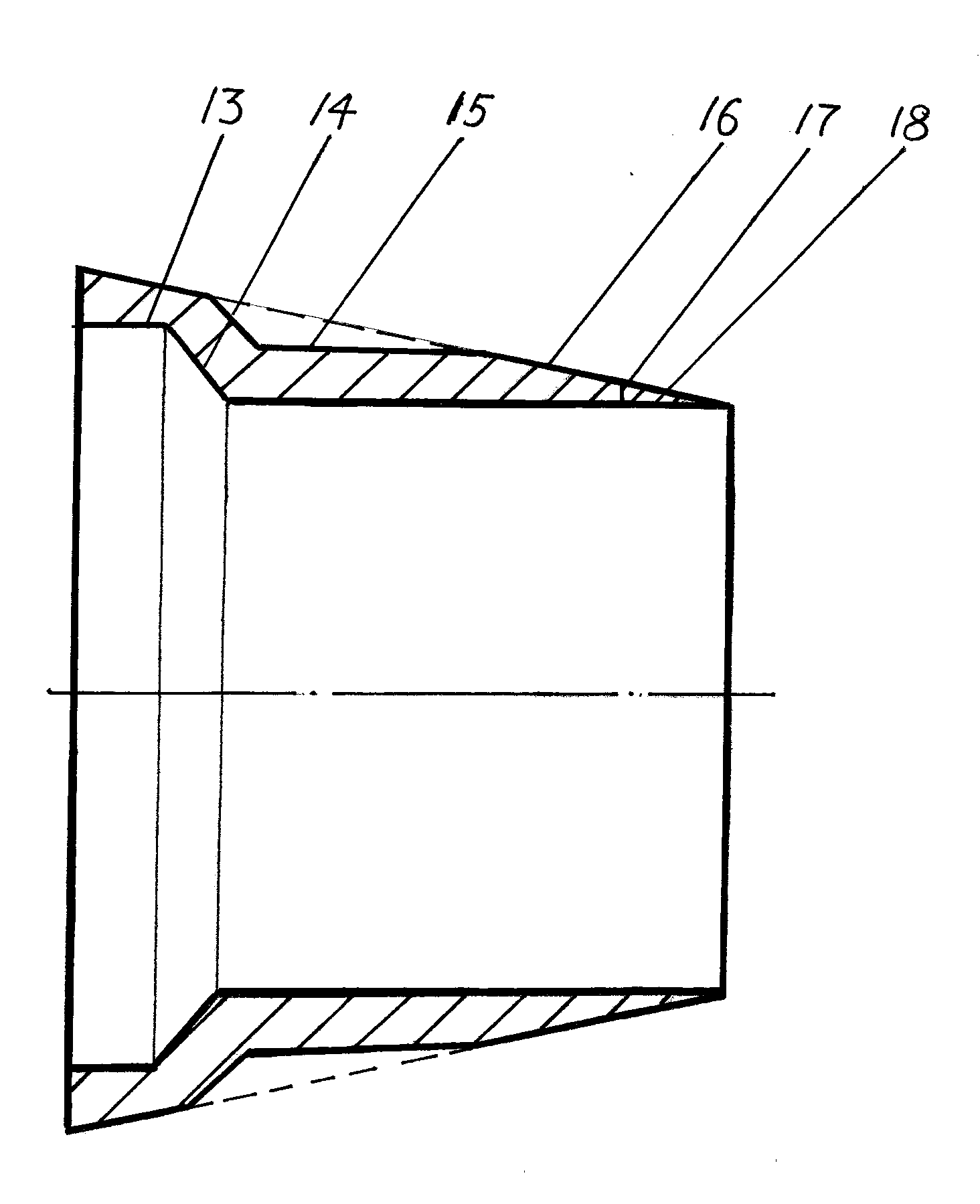

A pipeline connecting pipe fitting comprises a nut, a joint, a joint external cone table and a connection pipe horn port and is characterized in that an inner cone hole is formed in the nut, a clamp sleeve for match usage is arranged in the inner cone hole of the nut, the clamp sleeve is provided with a hollow clamp sleeve hole, a clamp sleeve inner cone hole is formed in the bottom of the clamp sleeve hole and consists of a clamp sleeve inner cylinder hole and a clamp sleeve inner cone hole horn groove, the clamp sleeve inner cylinder hole is provided with a seal cone surface, a clamp sleeve hole wall and a clamp sleeve outer cone inclined surface form a clamp sleeve cone inclined angle, the joint outer cone table extrudes the seal cone surface to achieve cone surface sealing, the joint outer cone table extrudes the connection pipe horn port in the clamp sleeve inner cone hole horn groove to achieve horn groove sealing, and the nut inner cone hole extrudes the clamp sleeve to extrude a connection pipe to achieve clamp sleeve sealing. The pipeline connecting pipe fitting has the advantages that seal connection is convenient, seal process requirements are low, seal properties are high, the pipeline connecting pipe fitting can be applied to connection of low-hardness thin-wall metal pipes made of dissimilar materials and can be completely interchanged with connection nuts in the prior art.

Owner:孙海潮

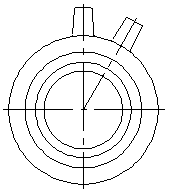

Solid insulated sleeve with inserting type connection

InactiveCN102957122AReduce construction costsEasy wiringSwitchgear arrangementsCable junctionsConductive coatingSilicon

The invention discloses a solid insulated sleeve with inserting type connection, which solves the problems that the existing cabinet type gas-insulated metal-enclosed switching equipment is connected in a power supply system by adopting a mode of cable incoming and outgoing lines, is complex in structure and higher in cost and the construction cost of a substation is increased. The solid insulated sleeve is characterized in that the surface of the solid insulated layer contains a large sleeve conical surface and a small sleeve conical surface; the transitional part of the large sleeve conical surface and the small sleeve conical surface is provided with a sleeve stepped boss; the outer surface of the large sleeve conical surface is provided with a silicon-rubber umbrella skirt; the outer edge of a low step of the stepped boss is provided with an installation flange; the contact part of the installation flange and the solid insulated layer is coated with a conductive coating; and the small sleeve conical surface is sheathed with a prefabricated silicon rubber inner conical sleeve. The solid insulated sleeve disclosed by the invention has the beneficial effects that wiring of the power supply system in a substation is simplified, the installation and connection of the equipment are simpler and more reliable, the manufacturing cost of the equipment and the construction cost of the substation are reduced, the creepage resistance and the foul resistance of the solid insulated sleeve are improved, and the continuity and the reliability of grounding of the installation flange are improved.

Owner:沈阳华利能源设备制造有限公司

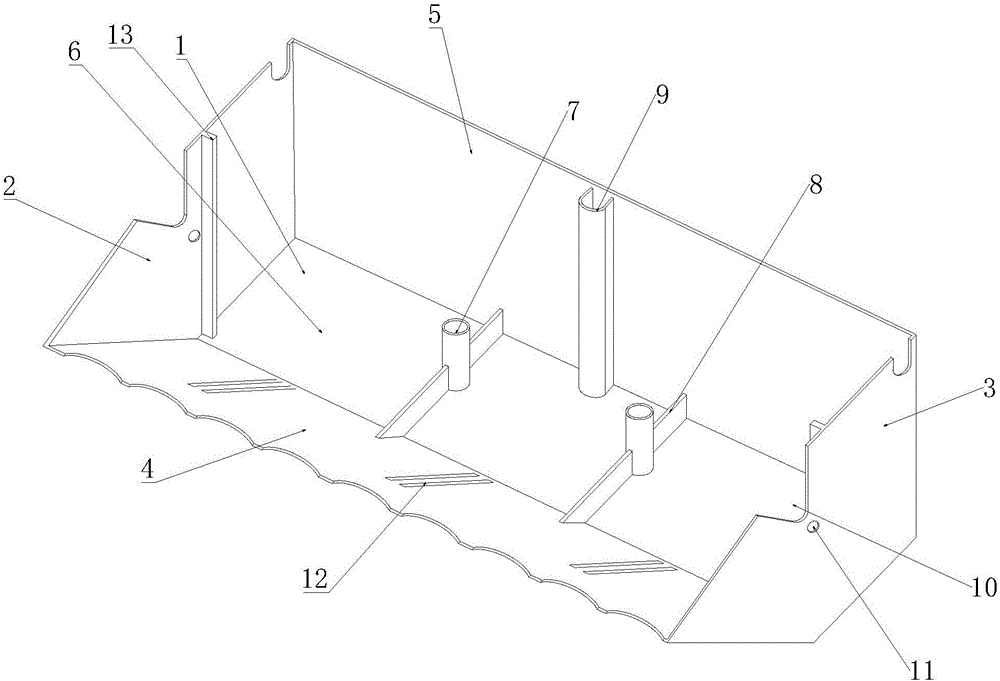

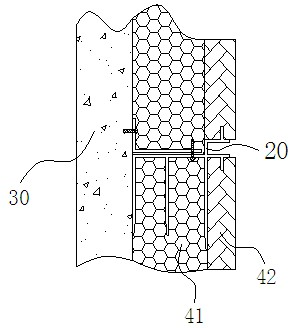

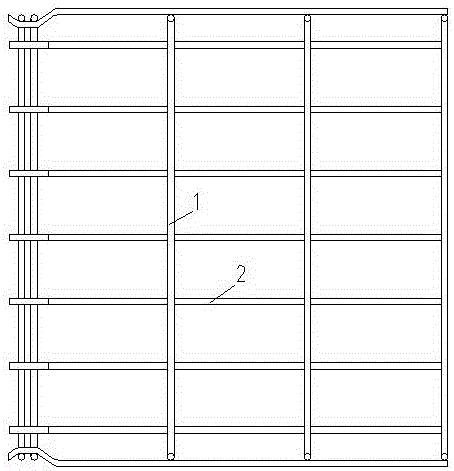

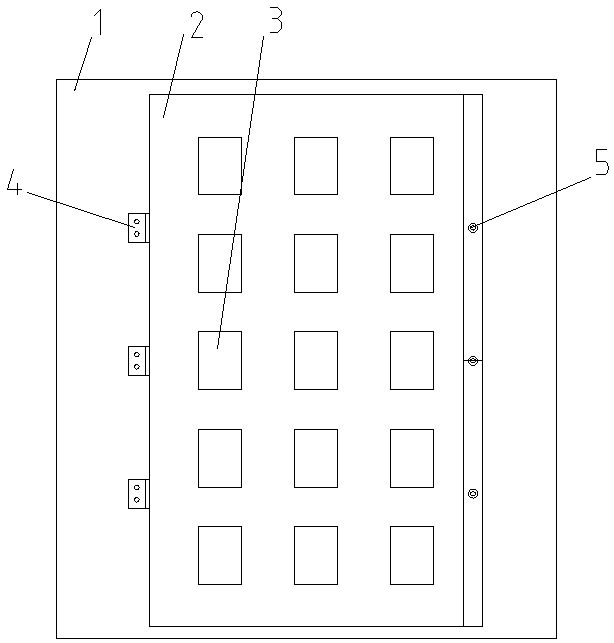

Fast-assembled integrated house wall plate corner connecting column

InactiveCN103912076AHigh strengthImprove thermal insulation and energy savingWallsHeat proofingEconomic benefitsEngineering

The invention discloses a fast-assembled integrated house wall plate corner connecting column. A panel of the connecting column is provided with at least two notches in insertion assembling with a connecting piece, inserts are embedded into the notches, and inclined inserts are arranged on the two sides of the notches. The connecting column is of an L shape or T shape. A region defined by the notches is filled with inorganic composite heat preservation materials. By means of the fast-assembled integrated house wall plate corner connecting column, connecting integrity of all components is improved, and the strength of the connecting column is also improved; because a wall body is connected through the corner connecting column, the overall structural strength, overall rigidity and stability of a house are greatly improved, reliable, easy and fast wall plate installing and connection can be achieved, the heat preservation and energy saving performance of the wall plate is improved, cracking is reduced, the construction cycle is shortened, and economic benefits are improved.

Owner:河南德霖集成房屋有限公司

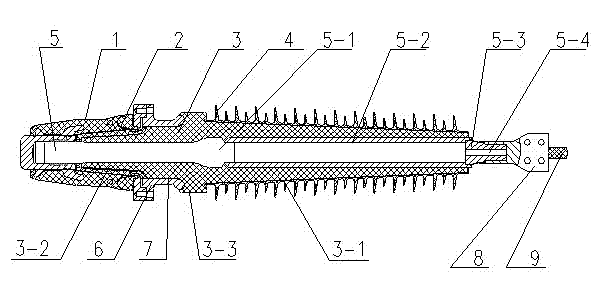

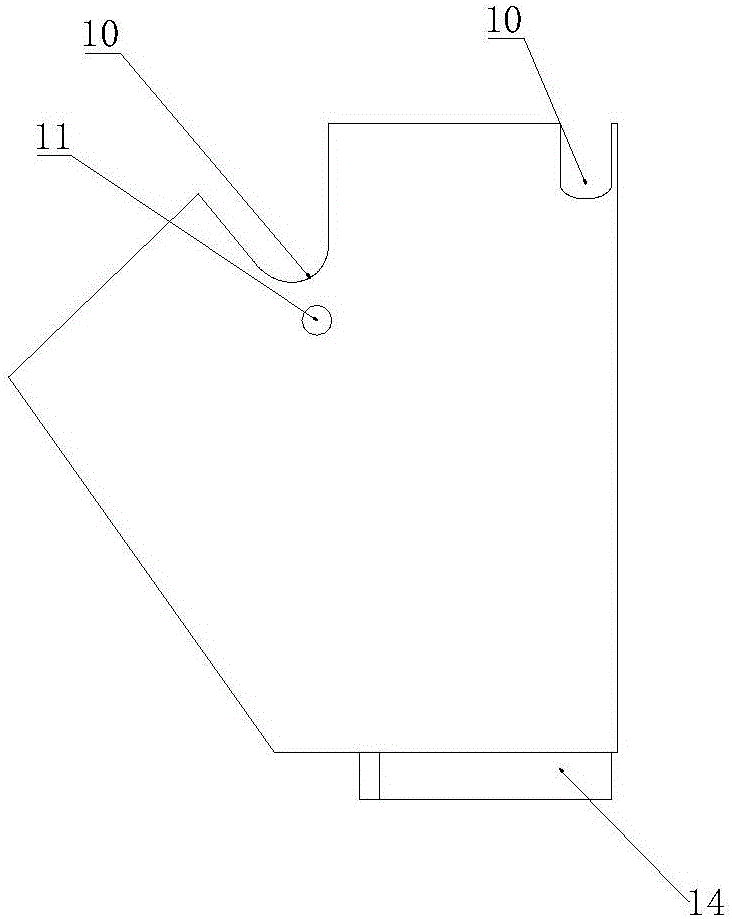

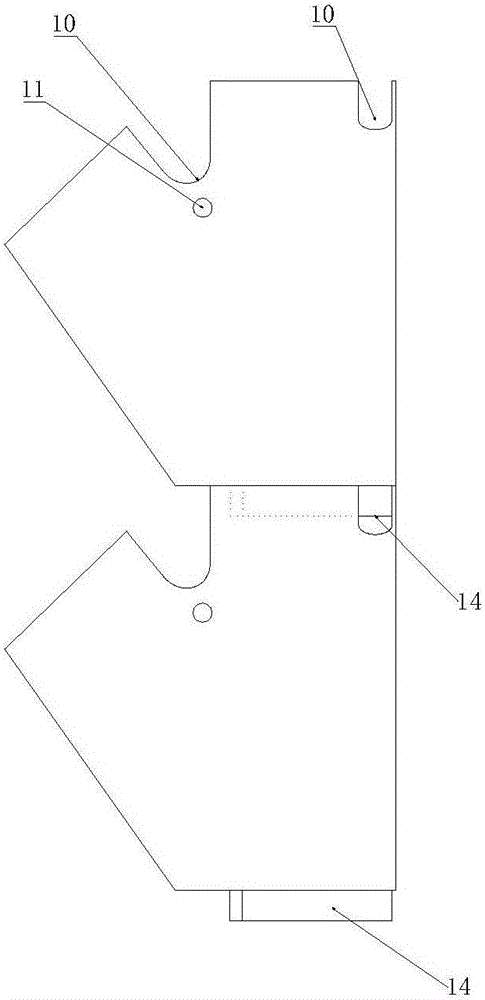

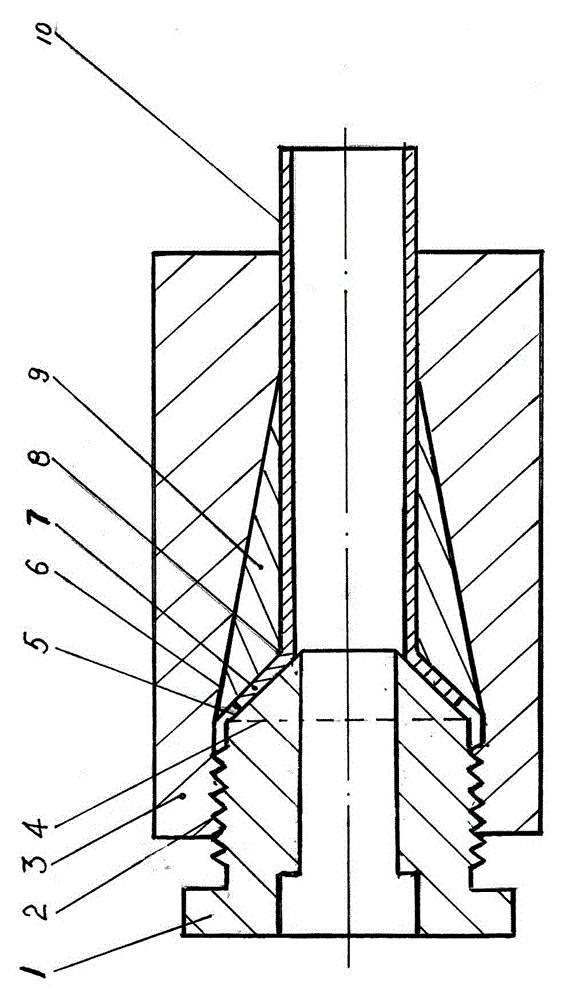

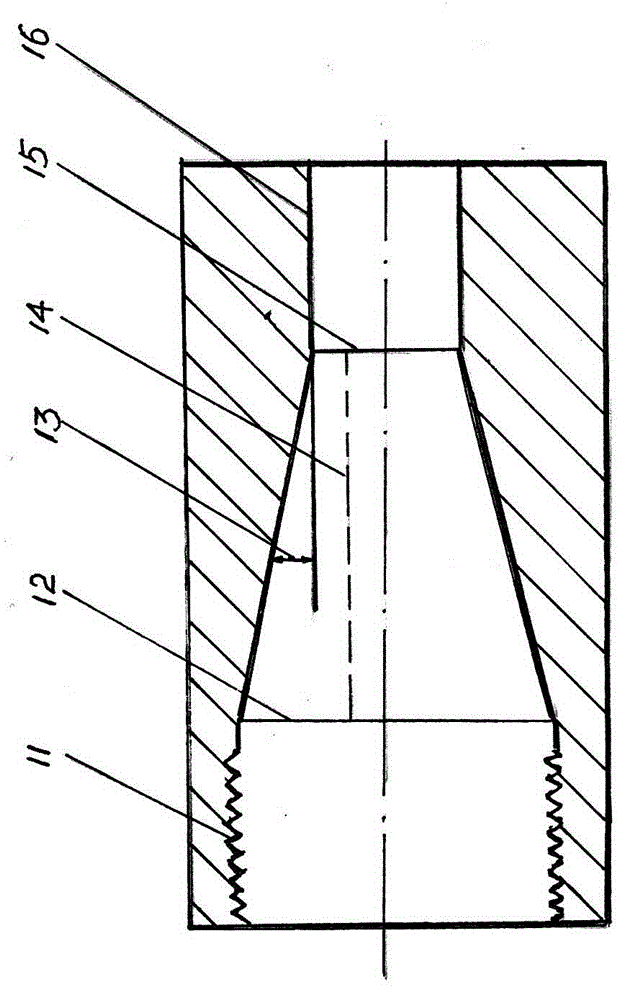

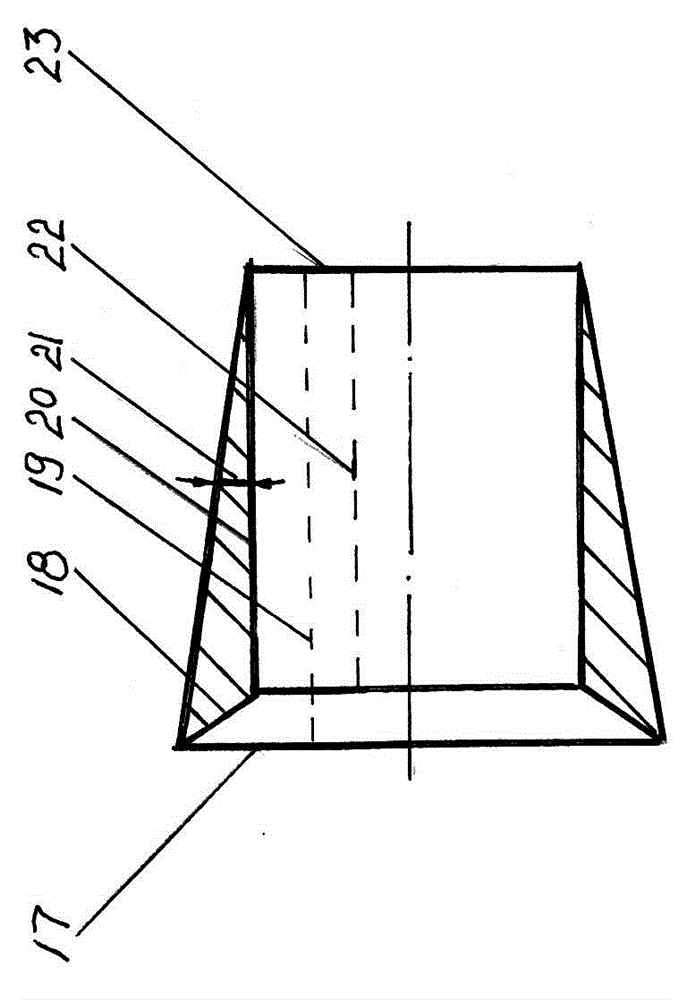

Pipeline connection pipe fitting

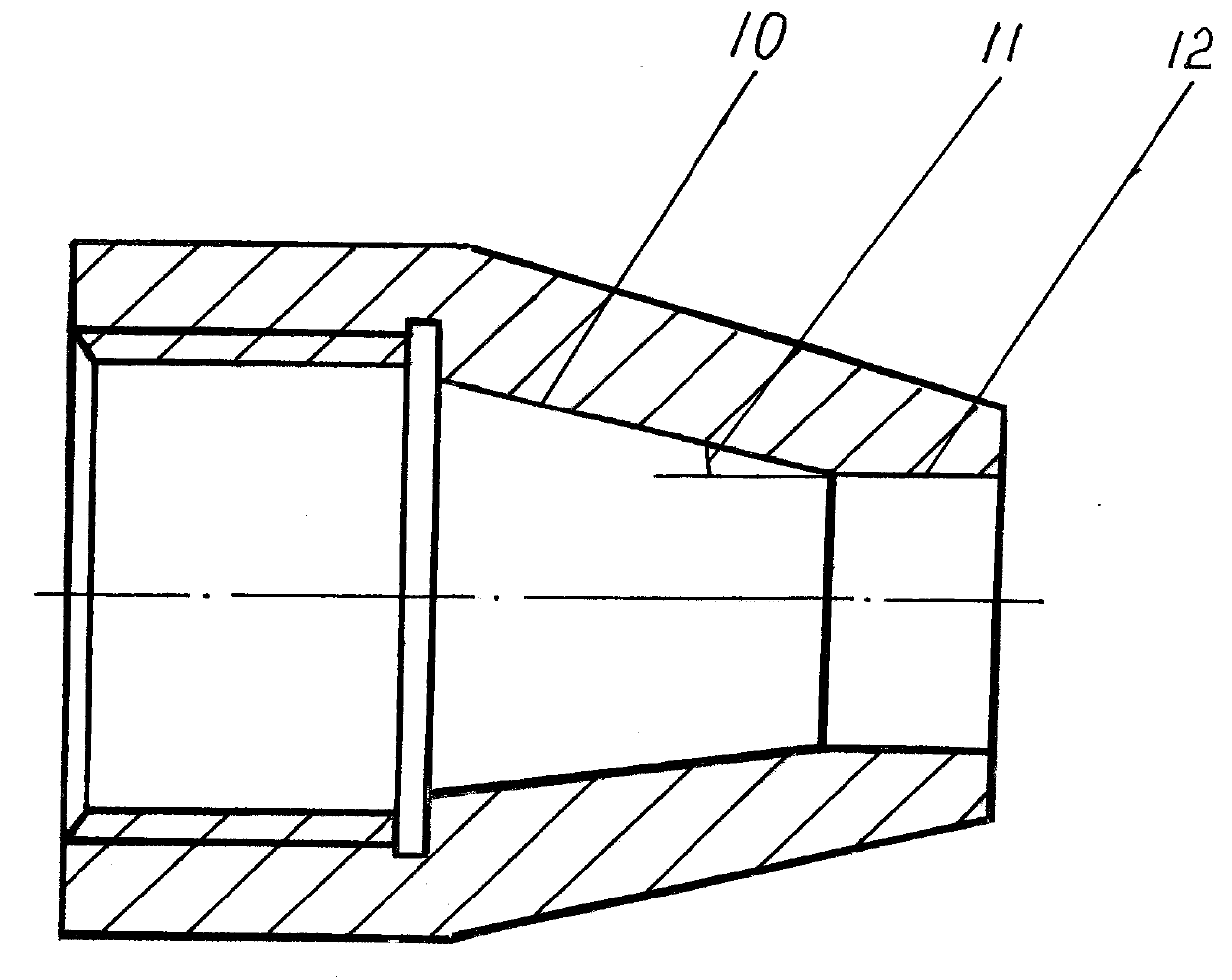

InactiveCN103604013AImprove sealingHigh resistance to disassembly torqueJoints with sealing surfacesPipe fittingOblique angle

A pipeline connection pipe fitting comprises a nut, a connector outer frustum and a connection pipe horn mouth. The pipeline connection pipe fitting is characterized in that the nut is provided with an inner taper hole, a taper sleeve is arranged in the nut inner taper hole and is a hollow taper sleeve hole, a taper sleeve inner taper hole is arranged at the bottom of the taper sleeve hole, a horn groove is arranged on the taper sleeve inner taper hole, and a taper sleeve taper oblique angle is formed by the taper sleeve hole wall and the taper sleeve outer taper oblique surface. The connector outer frustum extrudes the horn mouth and the taper sleeve inner taper hole, and extrudes the taper sleeve taper oblique angle to the position between the nut inner taper hole and a connection pipe to achieve sealing of the connection pipe and metal hard sealing between the connector outer frustum and the taper sleeve inner taper hole, and the connection pipe horn mouth is extruded to the position between the connector outer frustum and the horn groove to achieve sealing of the horn groove. The pipeline connection pipe fitting has the advantages of being convenient in sealing connection, low in requirement for sealing process, high in sealing performance, adaptive to connection of pipes made from heterogeneous materials and completely interchangeable with a connection nut in the prior art.

Owner:孙海潮

Stereoscopic greening box

InactiveCN105850555AFast installationReasonable structural designCultivating equipmentsReceptacle cultivationGreeningEngineering

The invention discloses a stereoscopic greening box, comprising a box body. The box body comprises a bottom plate and a plurality of side panels arranged on the bottom plate. The bottom plate and the side panels enclose to form at least one space for receiving green plants, the bottom plate or / and at least one side panel are provided with a connecting structure for fixing the box body or jointly connecting multiple box bodies, and the bottom plate or / and at least one side panel are provided with a drain structure. The stereoscopic greening box is reasonable in structural design, the structural design is considered fully in terms of water supply, supporting, fixing, assembly and even storage and transport, the mounting and connecting manner is more reliable, strength is higher, the water supply and drainage manner is reasonable, the mounting speed of a whole stereoscopic green wall is increased, and the stereoscopic greening box is more widely applicable.

Owner:肖健雄 +1

Pipe connecting pipe fitting

InactiveCN103759082AThe connection process requires the sameLower connection costsJoints with sealing surfacesPipe fittingEngineering

A pipe connecting pipe fitting comprises a nut, a joint, an external frustum of the joint and a horn mouth of a connecting pipe. The pipe connecting pipe fitting is characterized in that an inner taper hole is formed in the nut, a clamping sleeve used in cooperation is arranged in the inner taper hole of the nut, the clamping sleeve is provided with a hollow clamping sleeve hole, an inner taper hole of the clamping sleeve is formed in the bottom of the clamping sleeve hole, the inner taper hole of the clamping sleeve is composed of an inner cylindrical hole of the clamping sleeve and a horn groove of the inner taper hole of the clamping sleeve, the wall of the clamping sleeve hole and the external taper bevel of the clamping sleeve form a taper angle of the clamping sleeve, the external frustum of the joint extrudes the inner cylindrical hole of the clamping sleeve to achieve taper face sealing, the external frustum of the joint extrudes the horn mouth of the connecting pipe in the horn groove of the inner taper hole of the clamping sleeve to achieve horn groove sealing, and the inner taper hole of the nut extrudes the clamping sleeve so as to extrude the connecting pipe to achieve clamping sleeve sealing. The pipe connecting pipe fitting has the advantages that sealing connection is convenient and fast to operate, the sealing technological requirements are low, the sealing performance is high, and the pipe connecting pipe fitting can be used for connecting low-hardness thin-wall metal pipelines made of different materials and can be totally interchangeable with a connecting nut in the prior art.

Owner:孙海潮

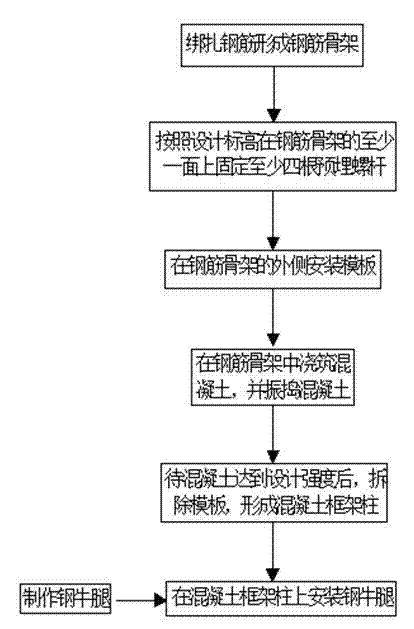

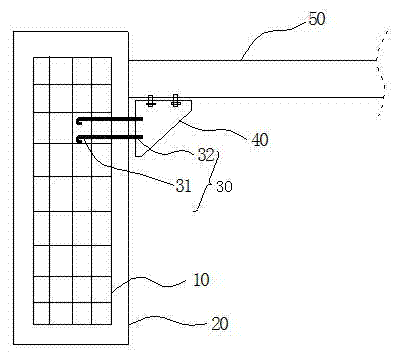

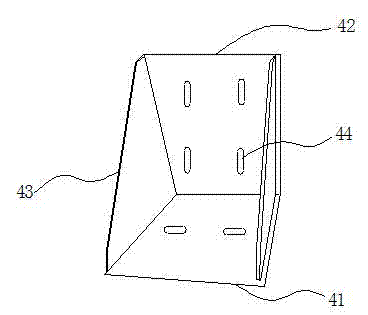

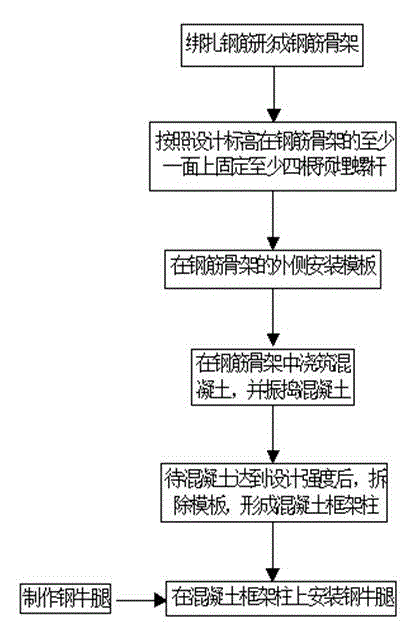

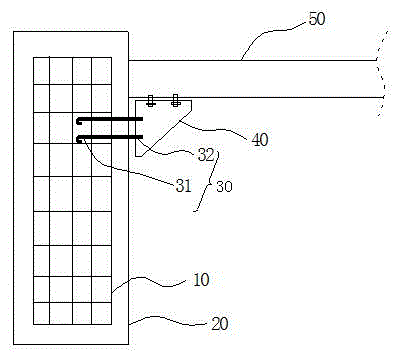

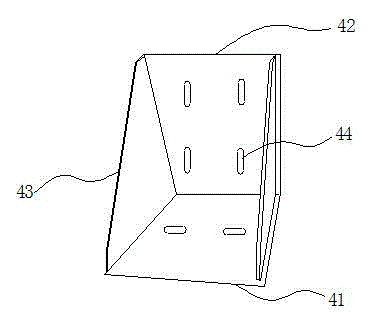

Construction method for arranging steel corbel on concrete frame column

InactiveCN103572973AEasy pouring and vibratingQuality assuranceBuilding material handlingRebarCorbel

The invention relates to a construction method for arranging a steel corbel on a concrete frame column. The construction method comprises the steps of assembling steel reinforcements to form a steel reinforcement framework, and fixing at least four pre-cast screws on at least one face of the steel reinforcement framework according to the designed elevation, wherein one end of each pre-cast screw and the steel reinforcements in the steel reinforcement framework are in point welding to be fixed, and the other end of each pre-cast screw is exposed out of the steel reinforcement framework; installing a formwork on the outer side of the steel reinforcement framework, wherein the portions, exposed out of the formwork, of the pre-cast screws are protected by being wound with adhesive plasters; pouring concrete in the steel reinforcement framework; after the concrete reaches the design strength, disassembling the formwork to form the concrete frame column; installing the steel corbel on the concrete frame column, wherein the steel corbel is provided with a plurality of transverse adjustable bolt holes, and the steel corbel is fixed on the pre-cast screws through bolt holes in an adjustable mode.

Owner:JIANGSU XIANGSEN CONSTR ENG

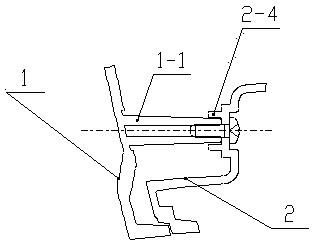

Automobile forward lighting combined lamp

ActiveCN103697390AEasy to replaceEasy to produceProtective devices for lightingOptical signallingEngineeringLight fixture

The invention relates to an automobile forward lighting combined lamp. The automobile forward lighting combined lamp consists of a lamp housing (2), a functional single lamp (1), a decorative cover (3) and an external dimming assembly, wherein the functional single lamp (1) is arranged on the lamp housing (2) through the external dimming assembly. The automobile forward lighting combined lamp is characterized in that the lamp housing (2) and the functional signal lamp (1) are installed by locking the functional single lamp (1) in a functional single lamp mounting hole (2-1) in the lamp housing (2) through the external dimming assembly, a tail lamp wire of the functional single lamp (1) penetrates through a functional single lamp outgoing wire hole (2-2) in the lamp housing (2), and then the decorative cover (3) is installed in a decorative cover mounting hole (2-4) in the lamp housing (2), so that limiting ribs (1-2) on the upper side and the lower side of the decorative cover (3) are used for limiting the lamp housing (2) in the X-axis direction and the Z-axis direction. According to the automobile forward lighting combined lamp, a lamp bulb is convenient to replace, the mounting connection is firm, and the universality is high.

Owner:JIANGSU WENGUANG VEHICLE ACCESSORIES

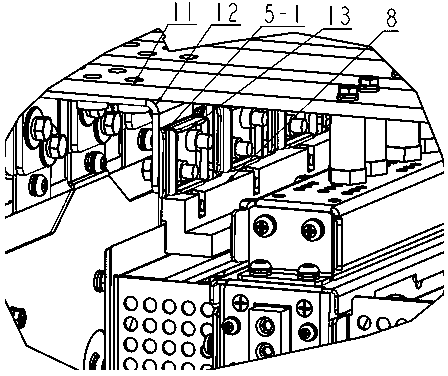

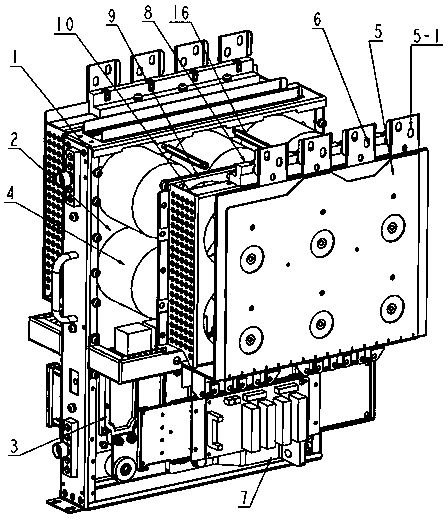

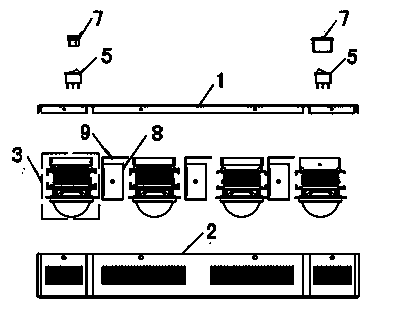

Power system structure

PendingCN104660016AAchieve high powerImprove power densityAc-dc conversionCooling/ventilation/heating modificationsCapacitanceBusbar

The invention relates to a power system structure which comprises a power module and a structure connected with a system, wherein a direct-current positive busbar is arranged above the power module; a direct-current negative busbar and a main bus copper bar are connected through a transfer copper bar; the structure connected with the system comprises a transfer copper bar nut plate and a compression module direct-current busbar leading-out terminal of the transfer copper bar; an alternating-current copper bar on the rear lower side of the power module is directly connected with an alternating-current copper bar of the system; a bus capacitor passes through a bus capacitor fixing plate, and a bus capacitor clamping plate and a capacitor clamping pull rod are fixed on a module fixing bracket and a water cooling plate; two terminals of the direct-current positive busbar and two terminals of the direct-current negative busbar are upward, are led out and are respectively connected with the main bus copper bar. With the adoption of the system structure and the power module structure provided by the invention, high power density, compact structure and a good water cooling heat dissipation effect of the bus capacitor and an IGBT (Insulated Gate Bipolar Transistor) can be realized; a direct-current copper bar and the alternating-current copper bar of the power module are respectively led out up and down; through a transfer structure, mounting and connection are reliable and convenient, and the characteristics of high power and compact structure are realized.

Owner:ZHEJIANG HAIDE NEW ENERGY

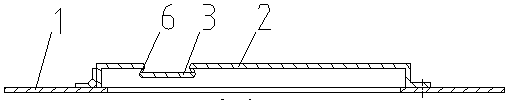

Connecting fastener for heat insulation and decoration integrated plate

InactiveCN102409828AEasy to install and connectEasy to installCovering/liningsThermal insulationFastener

The invention discloses a connecting fastener for a heat insulation and decoration integrated plate. The connecting fastener comprises a fixed piece connected with a wall and a connecting part connected with the heat insulation and decoration integrated plate, wherein the fixed piece and the connecting part are provided with connecting holes connected with the connecting part. The fastener comprises two independent parts which are connected into a whole through the connecting part, wherein the connecting holes in the fixed piece and the connecting part are strip holes, so that the connection can be properly adjusted in space, and the fixed piece can still be fixedly mounted if the local wall has a concave-convex part; and the position between the connecting part and the fixed piece is adjusted through the strip holes, so that the surface of the mounted heat insulation plate is flush. The invention has the advantages that: the connecting fastener is conveniently and reliably connected and mounted.

Owner:安徽根源光大高深新材料有限公司

Front fog lamp and daytime driving lamp combined lamp

InactiveCN104033820AAccelerate heat dissipationGuaranteed lifePoint-like light sourceElectric circuit arrangementsEngineeringLight source

A front fog lamp and daytime driving lamp combined lamp is composed of an upper cover, a lower cover, multiple sets of light source radiating modules, a fan, a switch, a power source plug wiring port and a power source socket. The light source radiating modules are arranged between the upper cover and the lower cover, and a power source box is arranged between each two adjacent light source radiating modules. The front fog lamp and daytime driving lamp combined lamp is characterized in that each convex lens module is embedded on the upper cover, an integrated light source and a light condensing cup are fixed at the bottom of each convex lens module through a sealing ring, a radiator is arranged on each integrated light source, and a fan is arranged on each radiator. The front fog lamp and daytime driving lamp combined lamp is simple in assembly, firm in mounting and connecting and reliable in quality, and rear-portion radiating space of the lamp is saved greatly; firmness in mounting and connecting is realized, and a wire harness inside the lamp is placed orderly, so that hidden on-fire trouble caused by the fact that the wire harness contacts with a bulb seat is prevented better.

Owner:徐林虎

Three-dimensional afforesting box

InactiveCN106665172AFast installationReasonable structural designSelf-acting watering devicesCultivating equipmentsEngineeringUltimate tensile strength

The invention discloses a three-dimensional afforesting box which comprises a box body, wherein the box body comprises a base plate and a plurality of lateral panels arranged on the base plate; at least one space used for accommodating green plants is encircled by the base plate and the lateral panels; a connecting structure used for fixing the box body or splicing a plurality of box bodies with each other is arranged on the base plate or / and at least one lateral panel; a drainage structure is formed on the base plate or / and at least one lateral panel. According to the invention, the structure design is reasonable; water supply, support, fixing, assembling and even storage transportation are fully considered for the structure design; the mounting connecting mode is more reliable; the strength is higher; the power supply and drainage modes are reasonable; the overall mounting speed of a three-dimensional afforesting wall is promoted; the application scope is wide.

Owner:刘志运

Circuit board structure with LED as light source

InactiveCN106402806AEasy to replaceSimple structureRoad vehiclesLight fasteningsEngineeringLED circuit

The invention provides a circuit board structure with an LED as a light source. The circuit board structure is characterized in that an LED circuit board is fixed on a bracket through hot riveting, and then fixed on a decorative cover or a lamp housing; the bracket for the LED circuit board is made of a plastic engineering material; a mounting screw hole is formed in the bracket for the LED circuit board; and hot riveting points for mounting of the LED circuit board are formed on the bracket for the LED circuit board. The circuit board structure provided by the invention is simple and has the advantages that the bulb replacement is convenient; the mounting and the connection are firm; and the universality is high.

Owner:李炳林

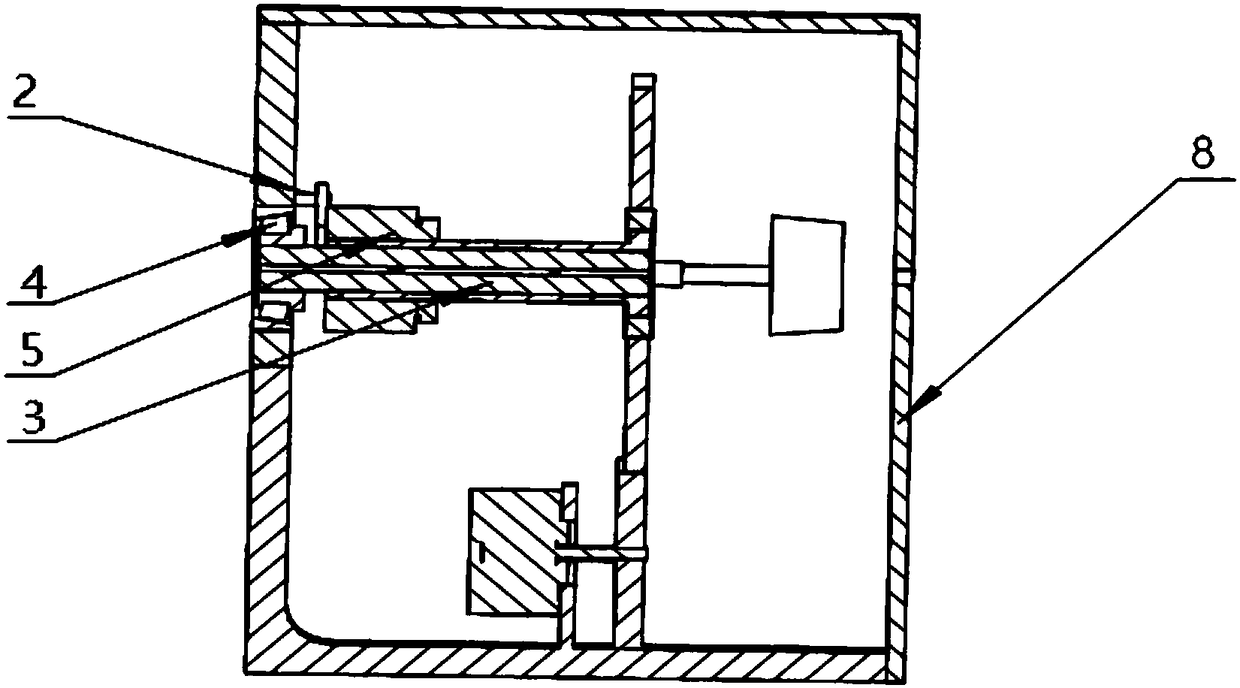

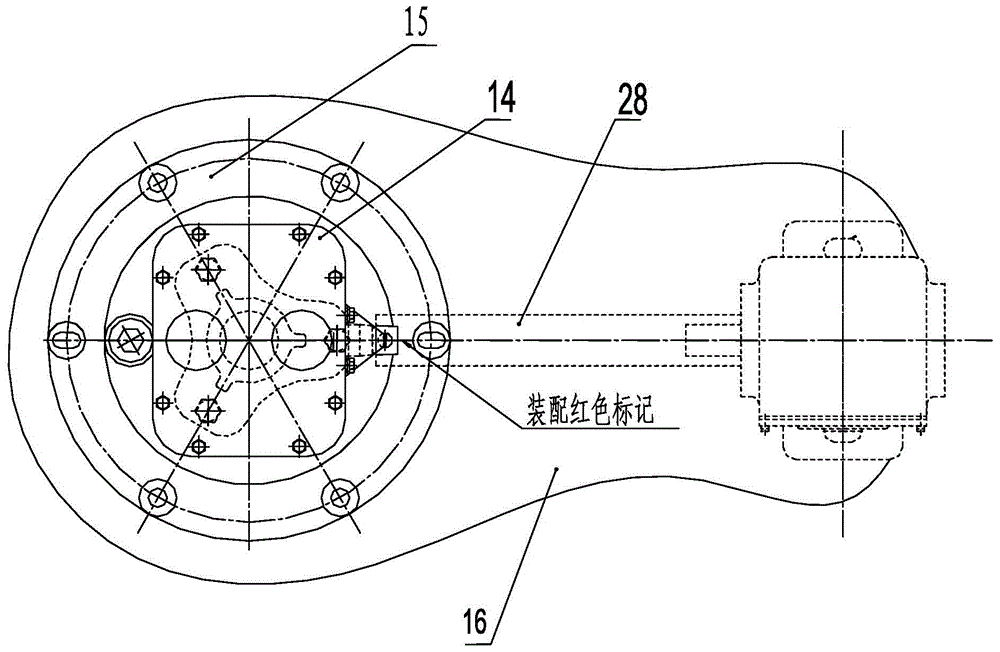

Giant magnetostrictive drive grinding machine

ActiveCN108274314AStrong reliabilityQuick responseGrinding carriagesRevolution surface grinding machinesControl systemFixed frame

The invention discloses a giant magnetostrictive drive grinding machine which comprises at least a pair of grinding heads, a fixing bracket, an electric slip ring fixing frame, a hollow shaft, an electric slip ring and a control system, wherein the electric slip ring fixing frame is mounted on the inner side of the fixing bracket; the hollow shaft is mounted on the fixing bracket through a bearing; the stator part of the electric slip ring is mounted on the electric slip ring fixing frame; the rotor part of the electric slip ring sleeves the hollow shaft and is connected with a fixing disc; the fixing disc is mounted at the other end of the hollow shaft as well as connected with a motor and a transmission mechanism; the grinding heads are driven by a micro stepper motor; the micro steppermotor and the grinding heads are slidably mounted on the fixing disc; and at least a pair of giant magnetostrictive mechanisms is arranged on the fixing disc and used for driving the grinding heads, so that the distance between the grinding heads can be adjusted. Through the giant magnetostrictive drive grinding machine, a workpiece can be circumferentially grinded under the circumstance that theworkpiece does not rotate; the giant magnetostrictive drive grinding machine is applicable to the circumstance that a long and thin workpiece needs to be circumferentially grinded or cannot rotate; and the grinding machining precision is high.

Owner:SHANGHAI INST OF TECH +1

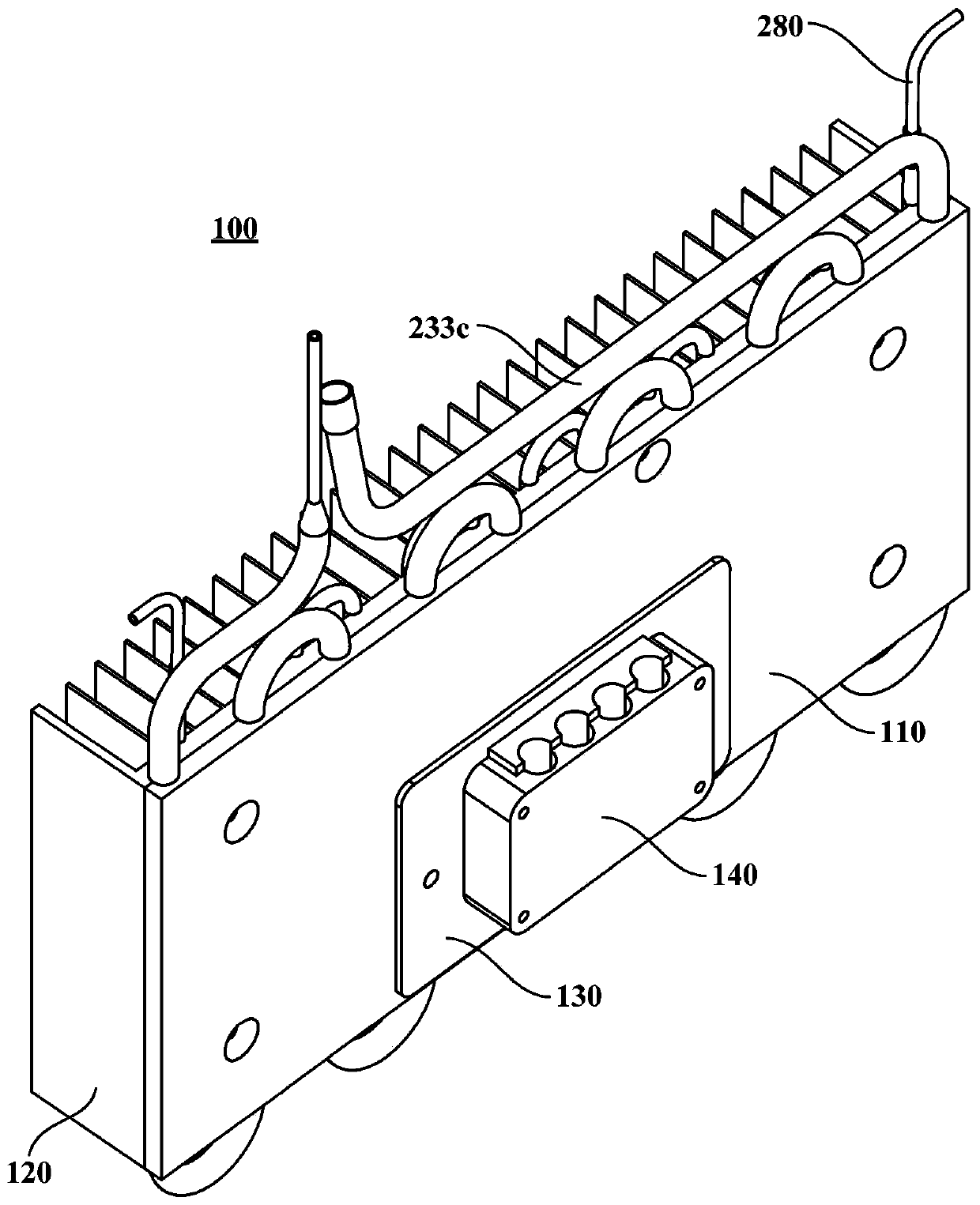

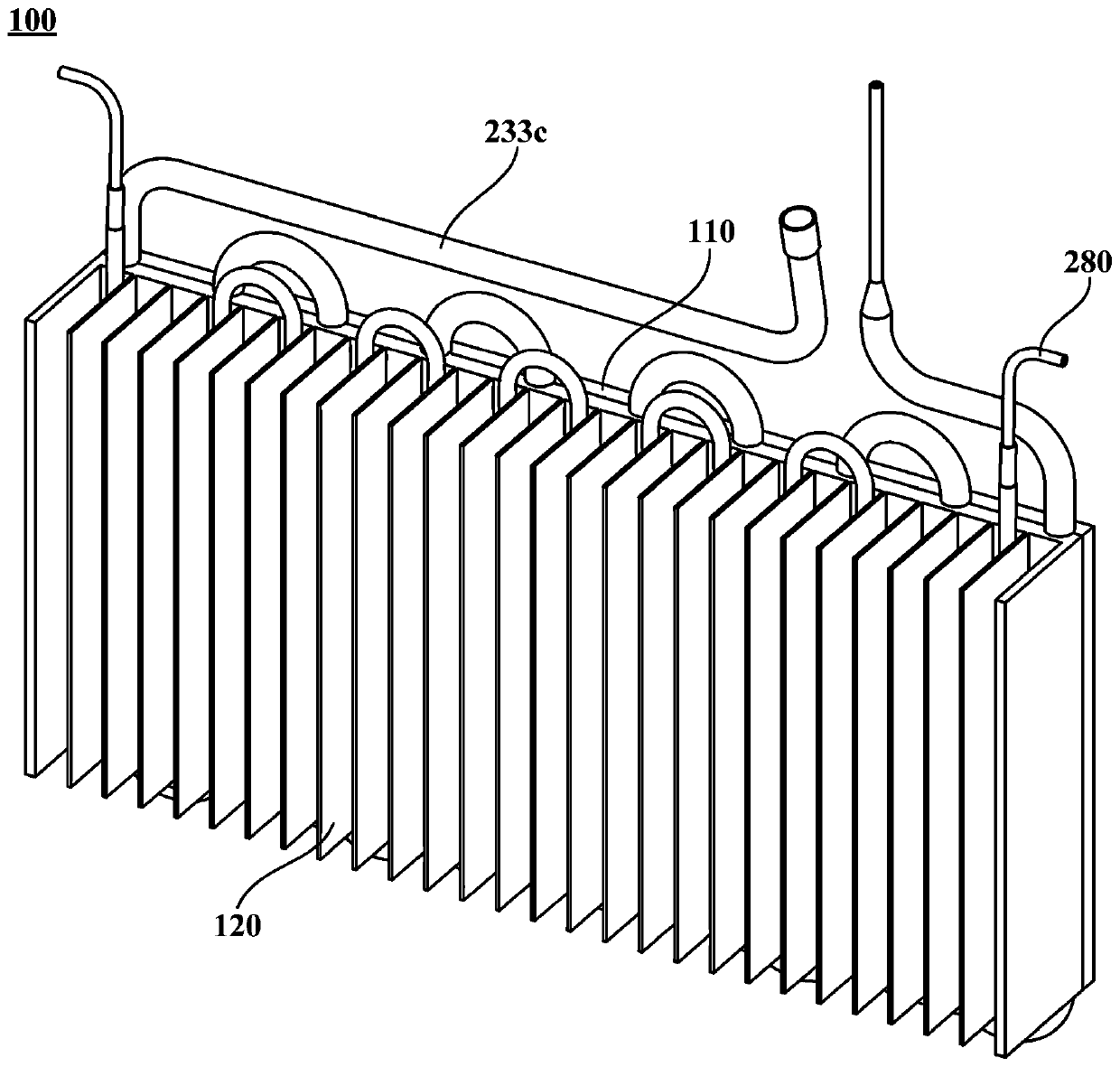

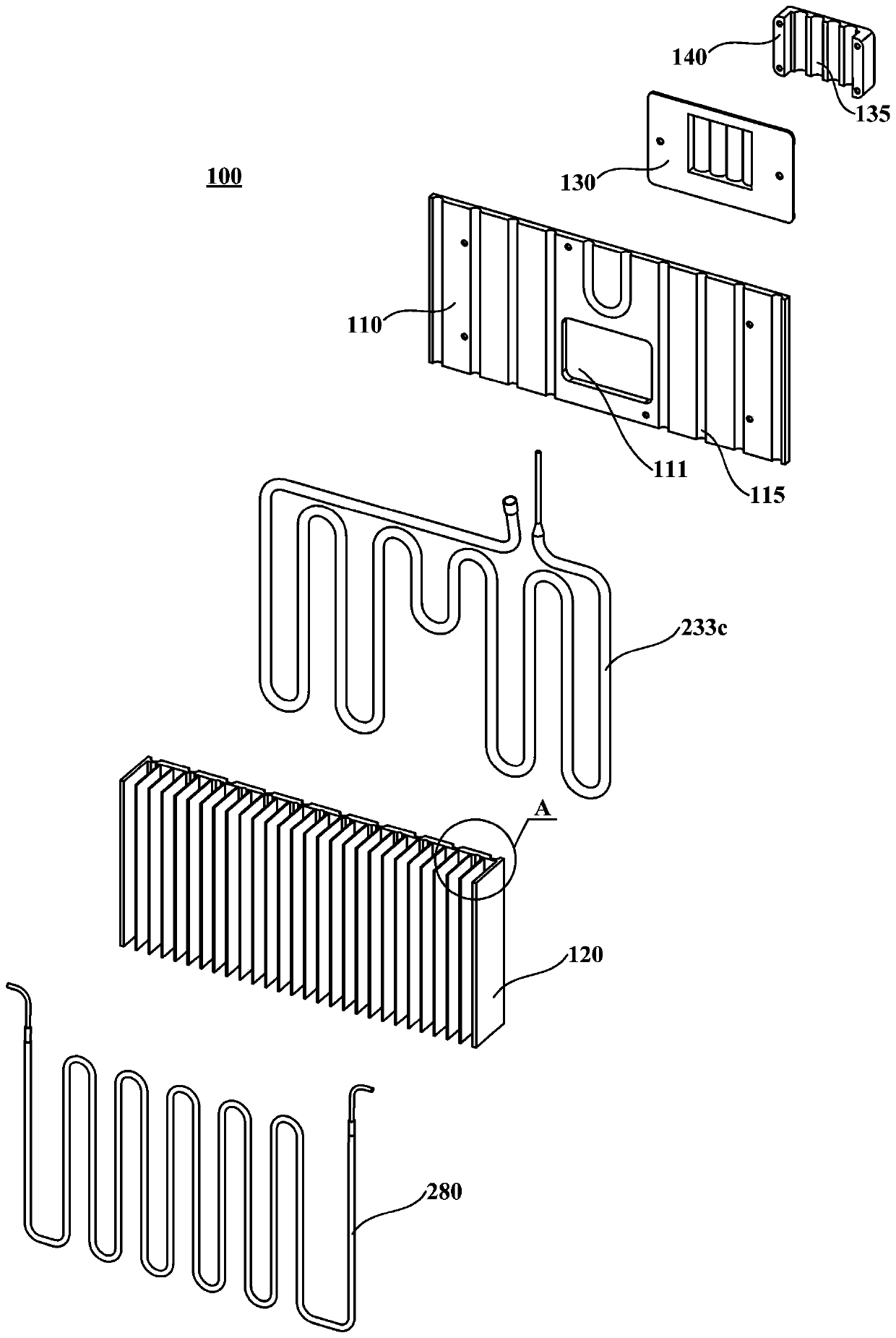

Refrigerating and freezing device

PendingCN111059832ARealize wide range temperature changeMeet the needs of useDomestic refrigeratorsCooling fluid circulationHeat conductingCool storage

The invention provides a refrigerating and freezing device. The refrigerating and freezing device comprises a box body, a heat exchanger, a vapor compression refrigerating system and a Stirling refrigerating system, wherein a copious cooling chamber is defined in the box body, the heat exchanger is at least partially arranged in the copious cooling chamber, the vapor compression refrigerating system comprises an evaporation pipe arranged in the copious cooling chamber, the evaporation pipe is arranged to be in heat connection with the heat exchanger, the Stirling refrigerating system comprisesa Stirling cryocooler, and the cold end of the Stirling cryocooler is arranged to be in thermal connection with the heat exchanger. According to the refrigerating and freezing device, a refrigerant pipe of the vapor compression refrigerating system and a cold conducting and heat conducting pipe of the Stirling refrigerating system are in heat connection with the heat exchanger, so that the refrigerating efficiency is high, wide-range temperature change of the copious cooling chamber can be further realized, the use requirements of different users are flexibly met, and the applicability is high.

Owner:QINGDAO HAIER SMART TECH R & D CO LTD +2

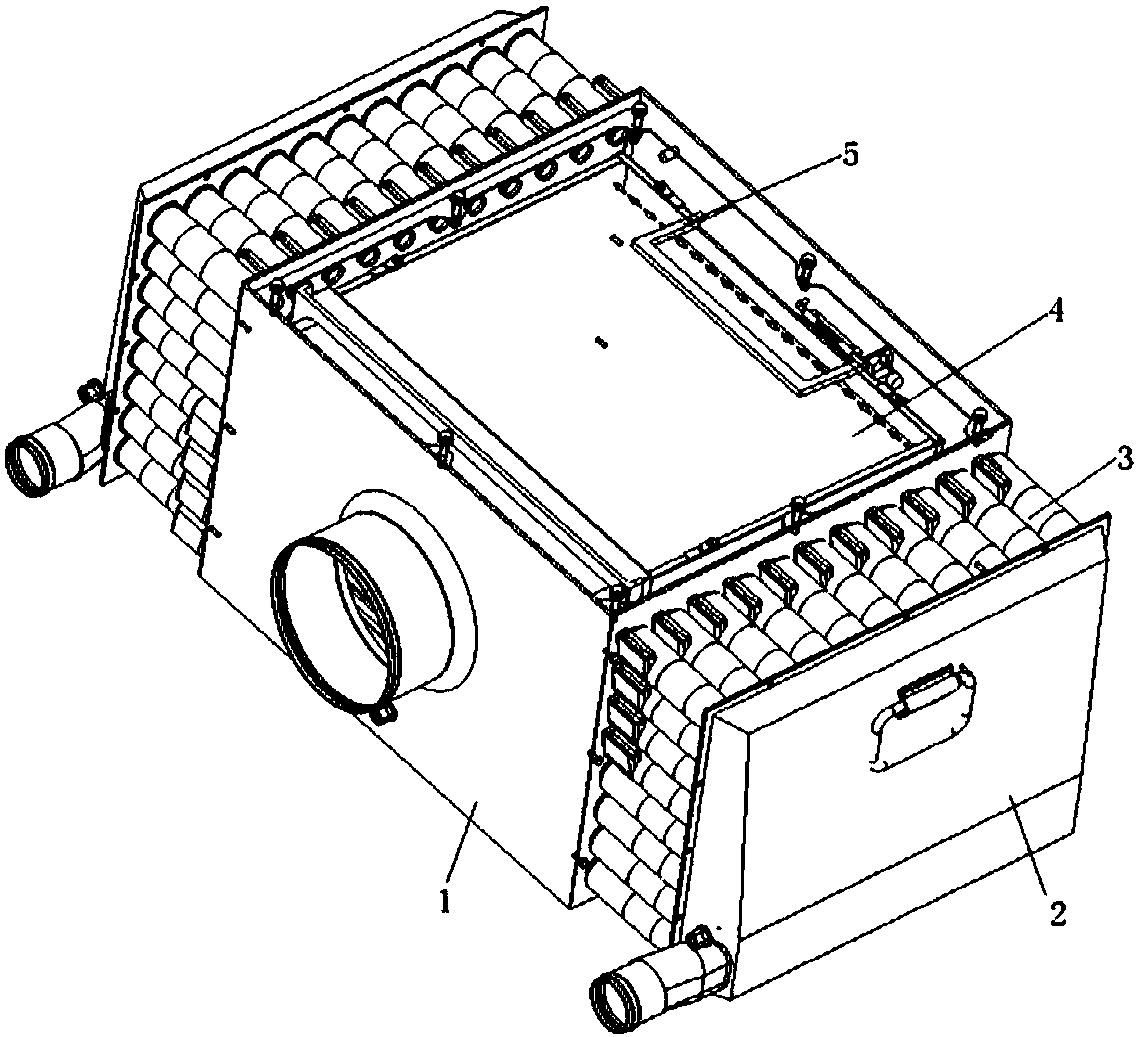

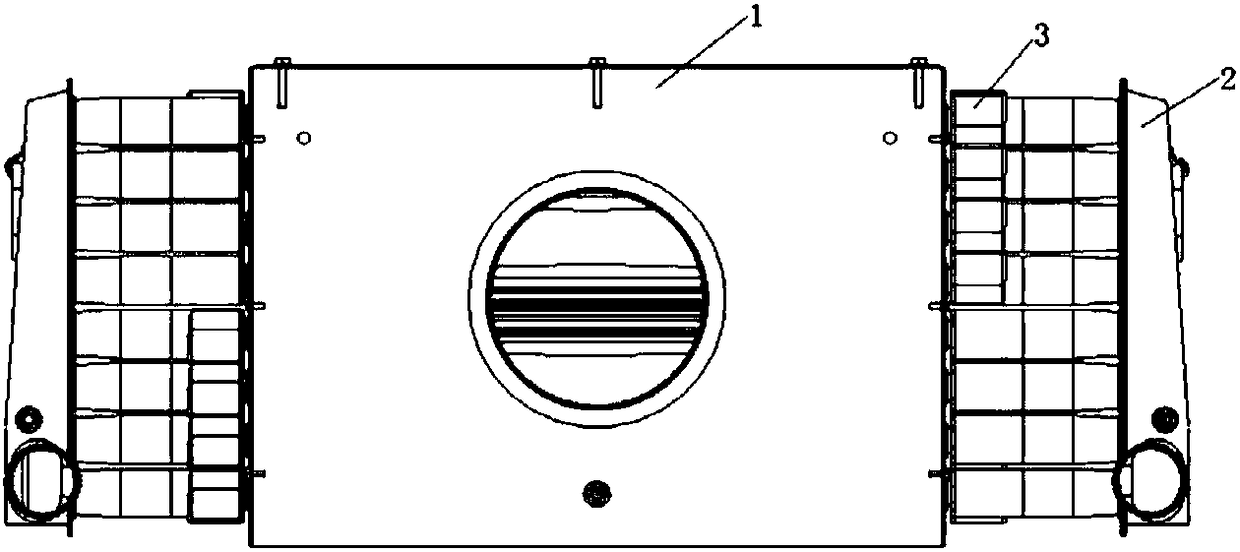

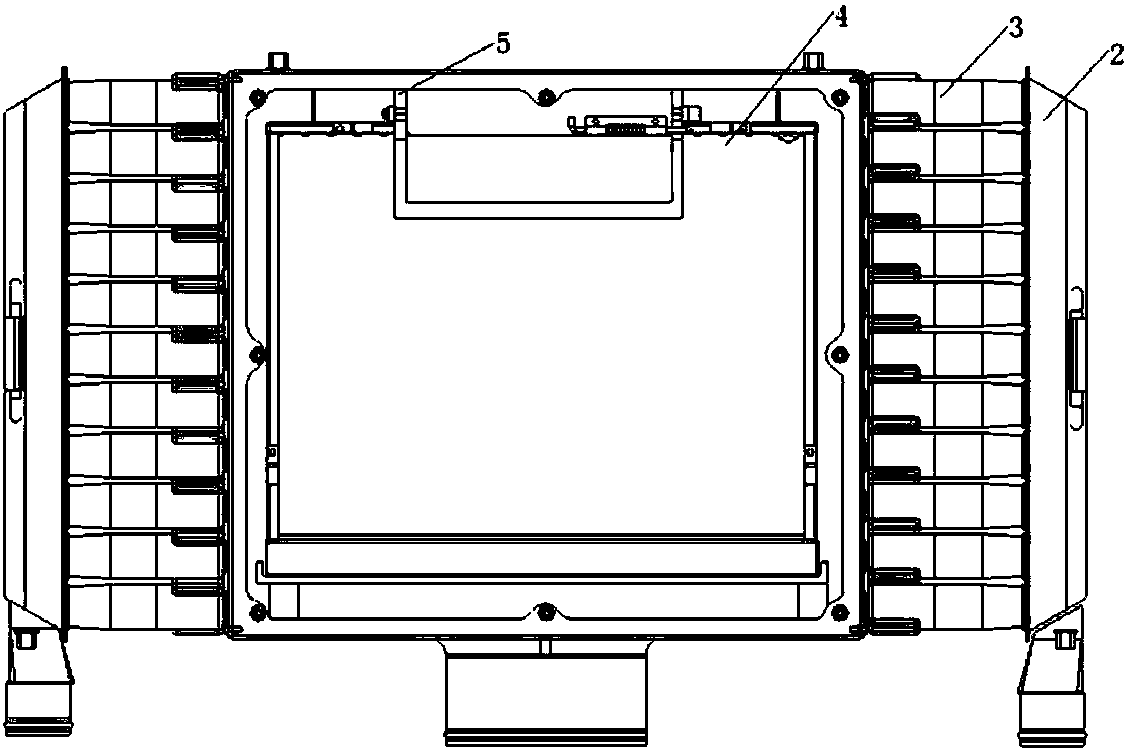

Special vehicle air cleaner

InactiveCN108131223AEfficient removalAvoid abrasionsMachines/enginesAir cleaners for fuelContinuous operationImpurity

The invention provides a special vehicle air cleaner. The air cleaner comprises an air cleaner housing, and an air outlet pipe and a dust outlet of a first-stage filter of the air cleaner are respectively connected with an air inlet of the air cleaner housing and an inlet of a dust exhaust housing. The air cleaner housing is internally provided with an air inflow separating plate which is verticalto an air outlet direction of the air outlet and includes a hole. The hole is provided with a second-stage filter on an air flow direction. The second-stage filter is a V-type filter. Through cooperation of the first-stage filter and the second-stage filter, the technical scheme can effectively remove impurity particles in air, and provides air whose purity is approach to 100% for an engine, andprevents abrasion and damages on internal components of the engine to the maximum extent. Even though in environment that dust content is high, long-time continuous operation of a vehicle can be guaranteed. The special vehicle air cleaner realizes characteristics of high air intake flow and slow resistance variation. The special vehicle air cleaner improves sealing property of filter element installation, and is simple and reliable in structure, and can be conveniently maintained and repaired.

Owner:CHINA NORTH VEHICLE RES INST

Shrinkage-preventing connector for integrated decoration plates

PendingCN108005331APrevent shrinkage deformationExtended service lifeCovering/liningsEngineeringElectrical and Electronics engineering

The invention discloses a shrinkage-preventing connector for integrated decoration plates. The shrinkage-preventing connector comprises a connector body, a plurality of oblique holes and a plurality of oblique teeth and is characterized in that the oblique holes are arranged in the connector body, a first included angle is formed between the central axis of each oblique hole and the connector body, the oblique teeth are arranged on the connector body, and the connector body, the oblique holes and the oblique teeth are of an integrated structure. The shrinkage-preventing connector has the advantages that the connector is embedded into each integrated decoration plate through the oblique holes in the connector body to connect and fix the integrated decoration plates, the oblique holes can guarantee mounting and connection stability and play a buffer role when the decoration plates have shrinkage deformation caused by temperature and the like, and deformation and cracking of the connecteddecoration plates are avoided; the oblique teeth on the connector body are neatly arranged, can play a decoration role and increase friction and further guarantee the firmness of the connection between the connector and the decoration plates; the connector is simple in structure, convenient to mount, capable of effectively preventing the shrinkage deformation of the integrated decoration plates and capable of prolonging the service life of the decoration plates.

Owner:嘉兴帝盛集成家居股份有限公司

Buckle structure and electronic device employing same

InactiveCN103635048ASimple structureEasy to installCasings/cabinets/drawers detailsMechanical engineeringElectron

The invention discloses a buckle structure arranged on a housing of an electronic device, and the buckle structure is firm in connection, easy in dismounting, and no specific tool is needed. The buckle structure comprises a connecting portion arranged on a second assembly on the housing of the electronic device; the connecting portion comprises a first arc elastic arm, a limit groove, a slide through hole, and a second arc elastic arm; the limit groove is positioned on an outer wall of the slide through hole; the buckle structure also comprises the buckle arranged on a first assembly on the housing of the electronic device; the buckle is provided with a positioning rib; the buckle is cooperated with the slide through hole in a slide manner, and the positioning rib is cooperated with the limit groove, thereby completing the connection and fixation of the electronic device first and second assemblies on the housing of the electronic device. The invention also discloses the electronic device employing the buckle structure.

Owner:COMBA TELECOM SYST CHINA LTD

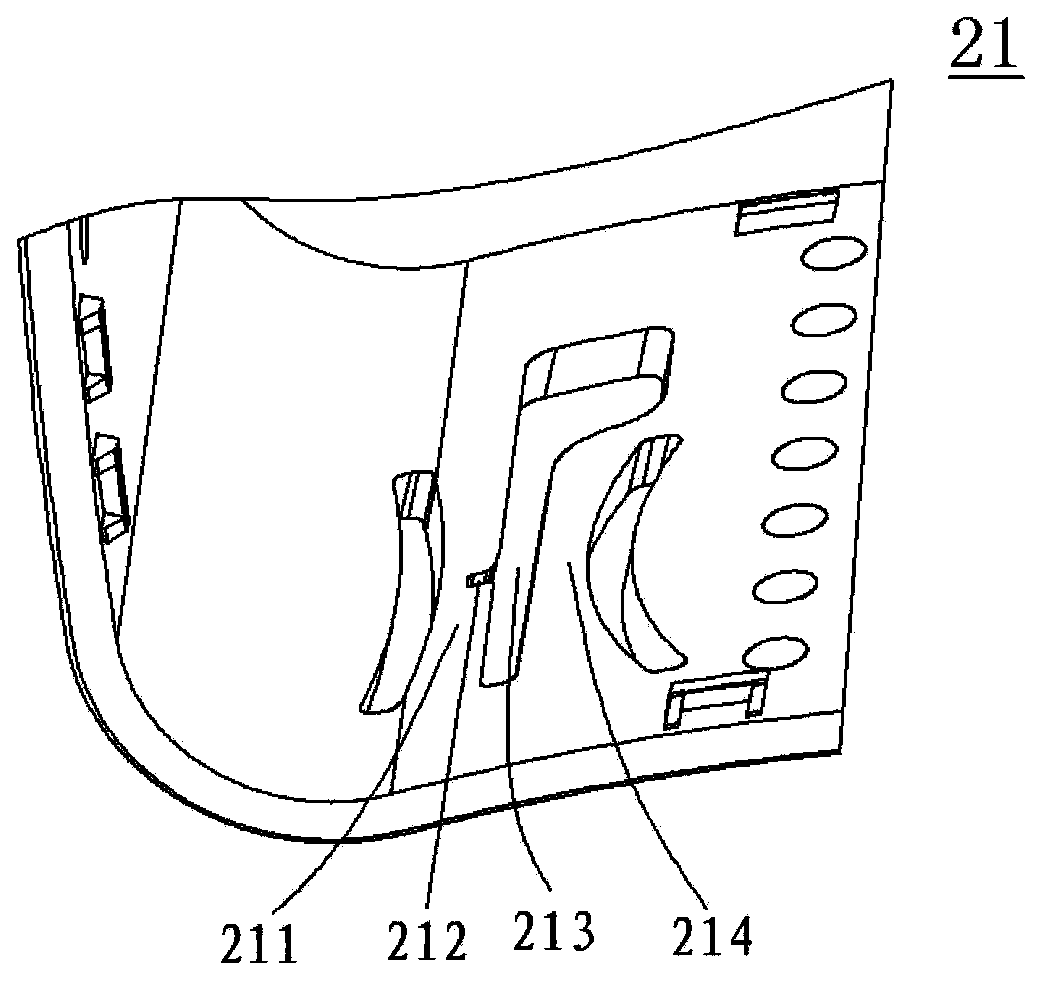

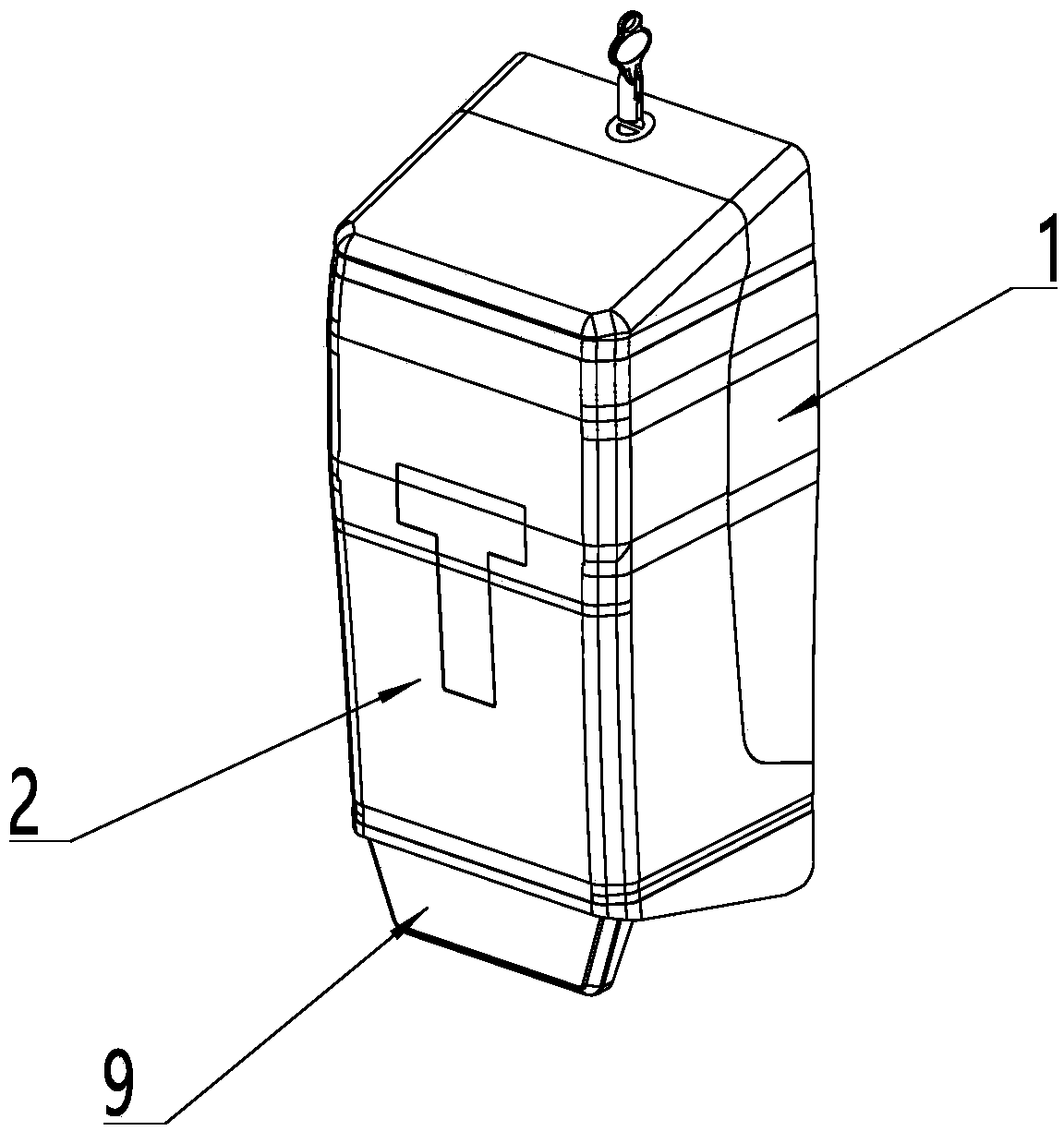

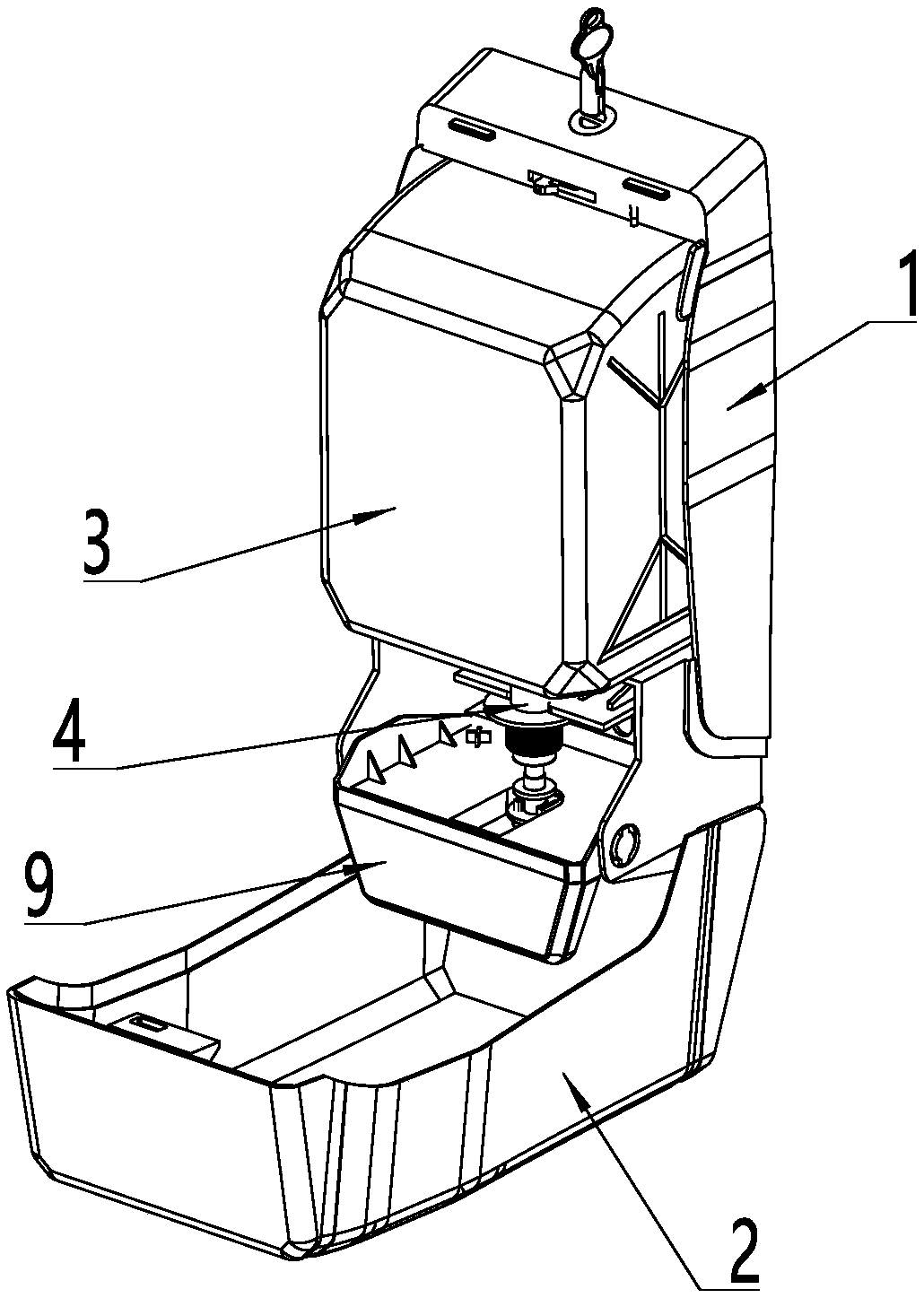

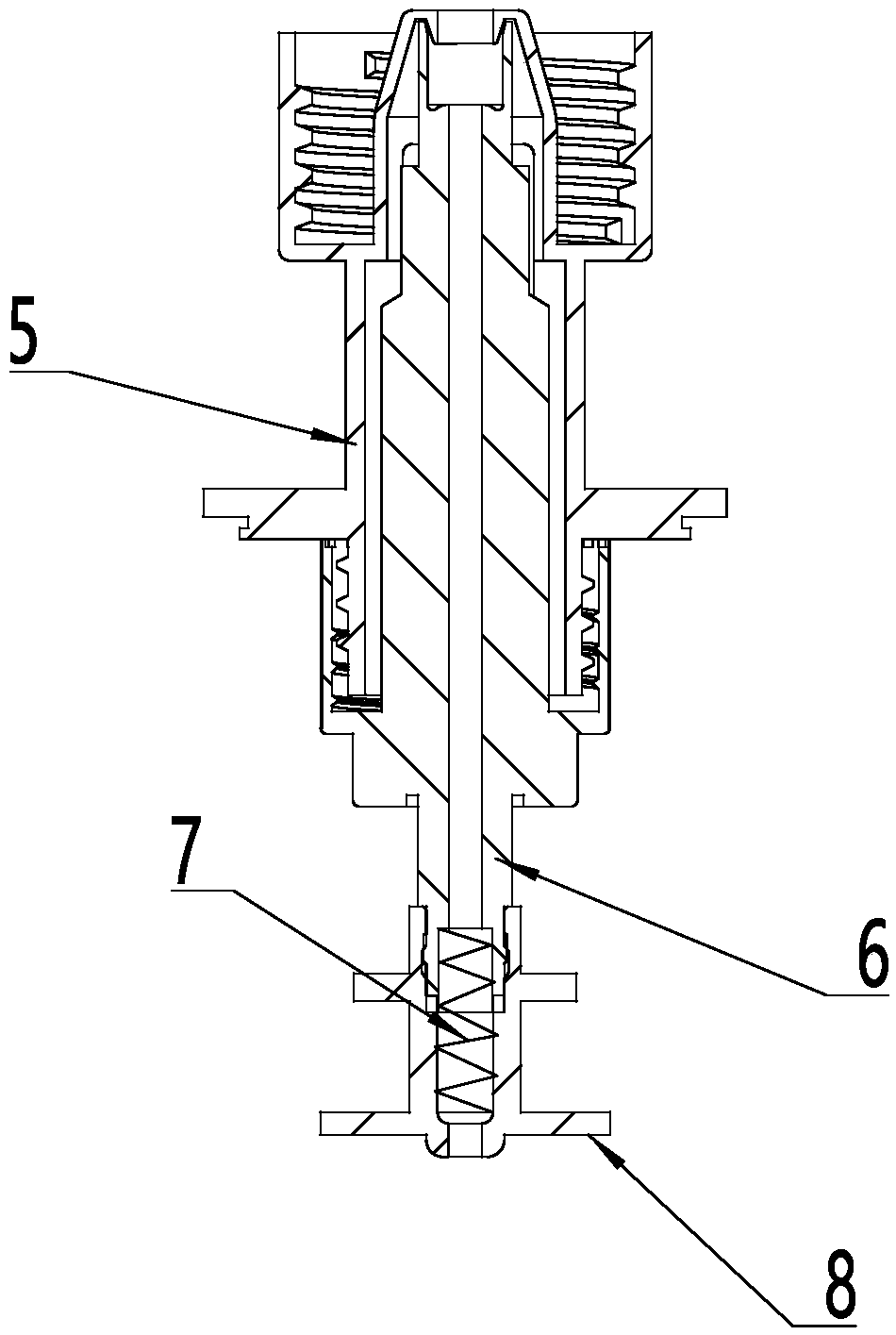

Liquid soap dispenser

InactiveCN109077641ASolve the problem of easy tippingSimple structureHolders and dispensersBottleFront cover

The invention discloses a liquid soap dispenser. The liquid soap dispenser comprises a base and a front cover rotationally installed on the base, a container used for containing liquid soap is embedded on the base, a pump head is communicated with the lower portion of the container, a switch cooperating with the pump head is rotationally installed on the lower portion of the base, the pump head comprises a pump body and a pump core movably sleeved with the pump body, the pump core is communicated with the container, and an elastic device used for making the pump core reset is installed in thepump body. In this way, the problem that a vertical pressing type bottled liquid soap dispenser is likely to turn over is solved, and meanwhile the problem that the bottom of a guide pipe cannot be completely soaked in the liquid soap at the bottle bottom, and the soap liquid is left at the bottle bottom is avoided; the liquid soap dispenser is simple in structure, capable of facilitating liquid replacing, liquid adding and cleaning, reliable in installation and connection, high in practicability and high in applicability.

Owner:JIANGMEN AYT ELECTRICAL APPLIANCE CO LTD

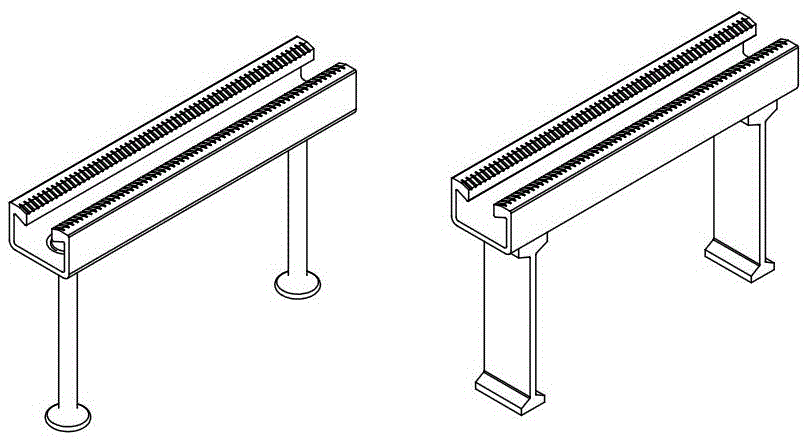

Steel mesh bridge

ActiveCN106786245AReduce in quantityFirmly connectedElectrical apparatusEconomic benefitsEngineering

The invention provides a steel mesh bridge consisting of a plurality of U-shaped cross beams and longitudinal ribs, wherein the connection points of the U-shaped cross beams and the longitudinal ribs are located on inner sides of the longitudinal ribs; at least one end of the steel mesh bridge is a head end provided with two U-shaped cross beams with a closer distance, a segment of the longitudinal rib connected with the two U-shaped cross beams on the head end is bent inward to form a groove, so that the two U-shaped cross beams on the head end are located in the groove of the longitudinal rib, the parts of two side edges and bottom margins of the two U-shaped cross beams on the head end of the steel mesh bridge located between two adjacent longitudinal ribs are provided with projections protruding to the outer sides, and the projections can limit the two side edges and bottom margins of the two U-shaped cross beams of the conventional steel mesh bridge so as to prevent drop-out; and no connection strap needs to be additionally arranged, thereby being convenient to install and connect, small in mass and volume, reliable to connect, convenient to install and transport, small in the number of parts and components, simple in production and manufacture processes, short in engineering construction time and high in economic benefit.

Owner:江苏国美钢网桥架有限公司

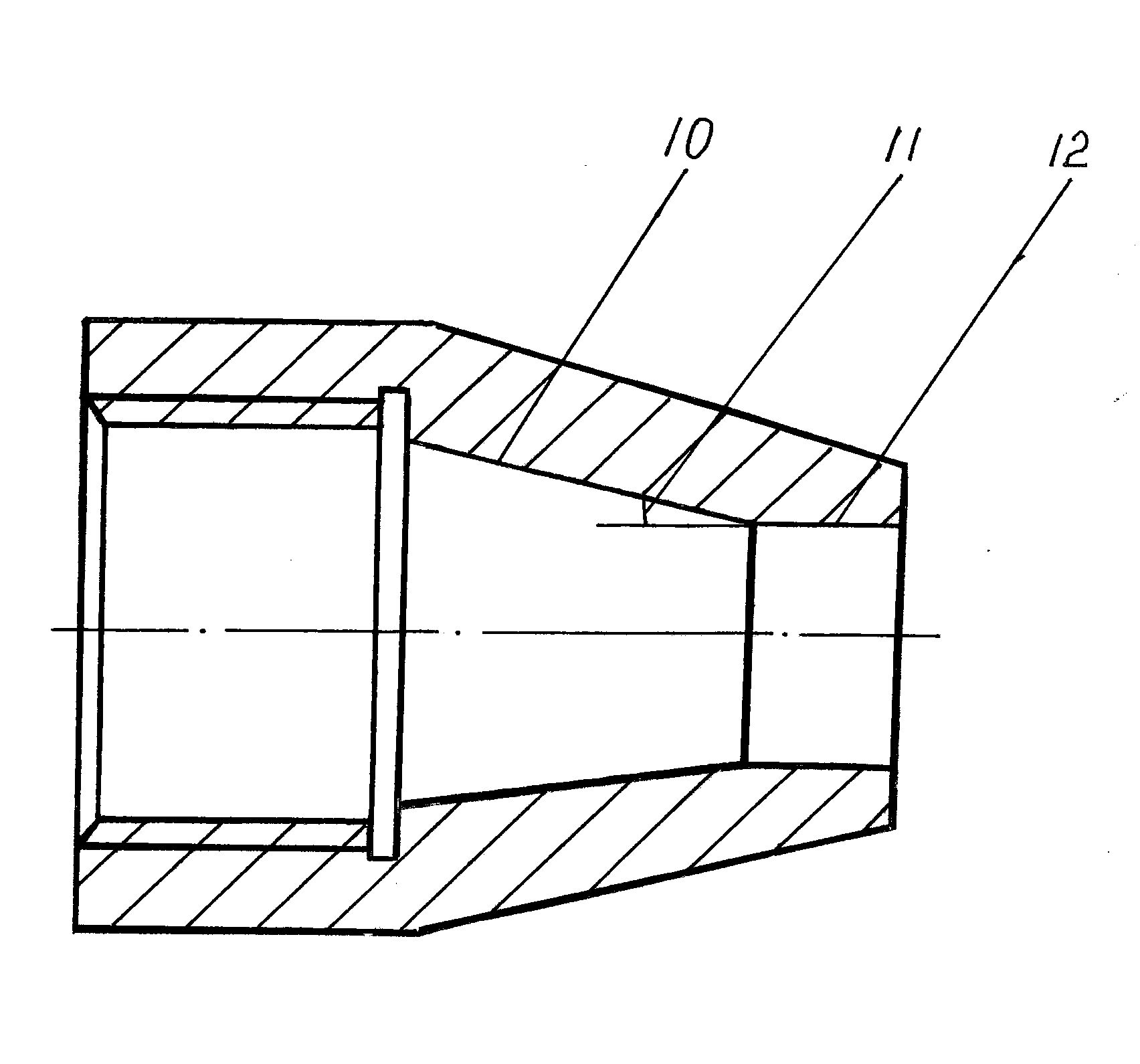

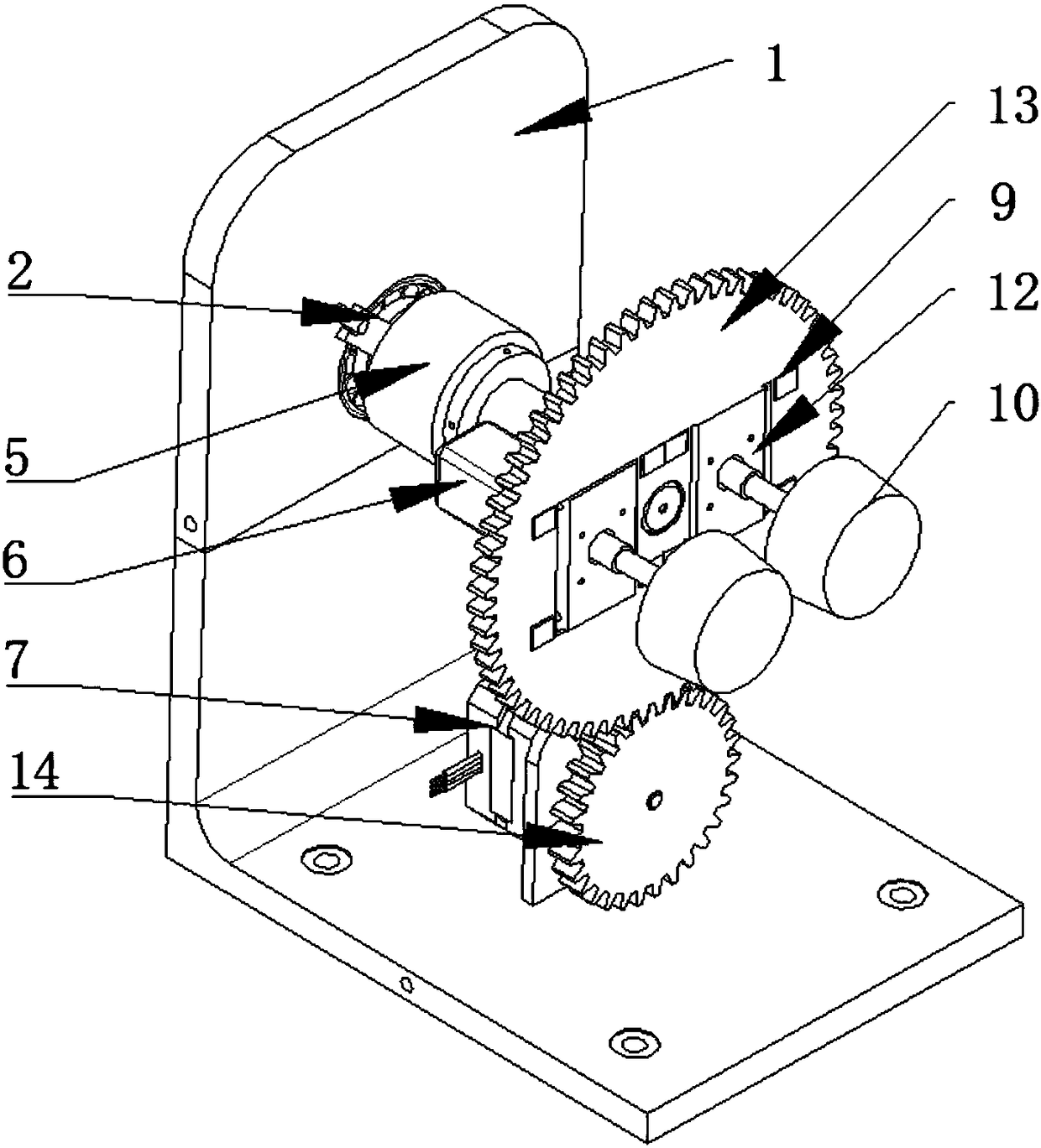

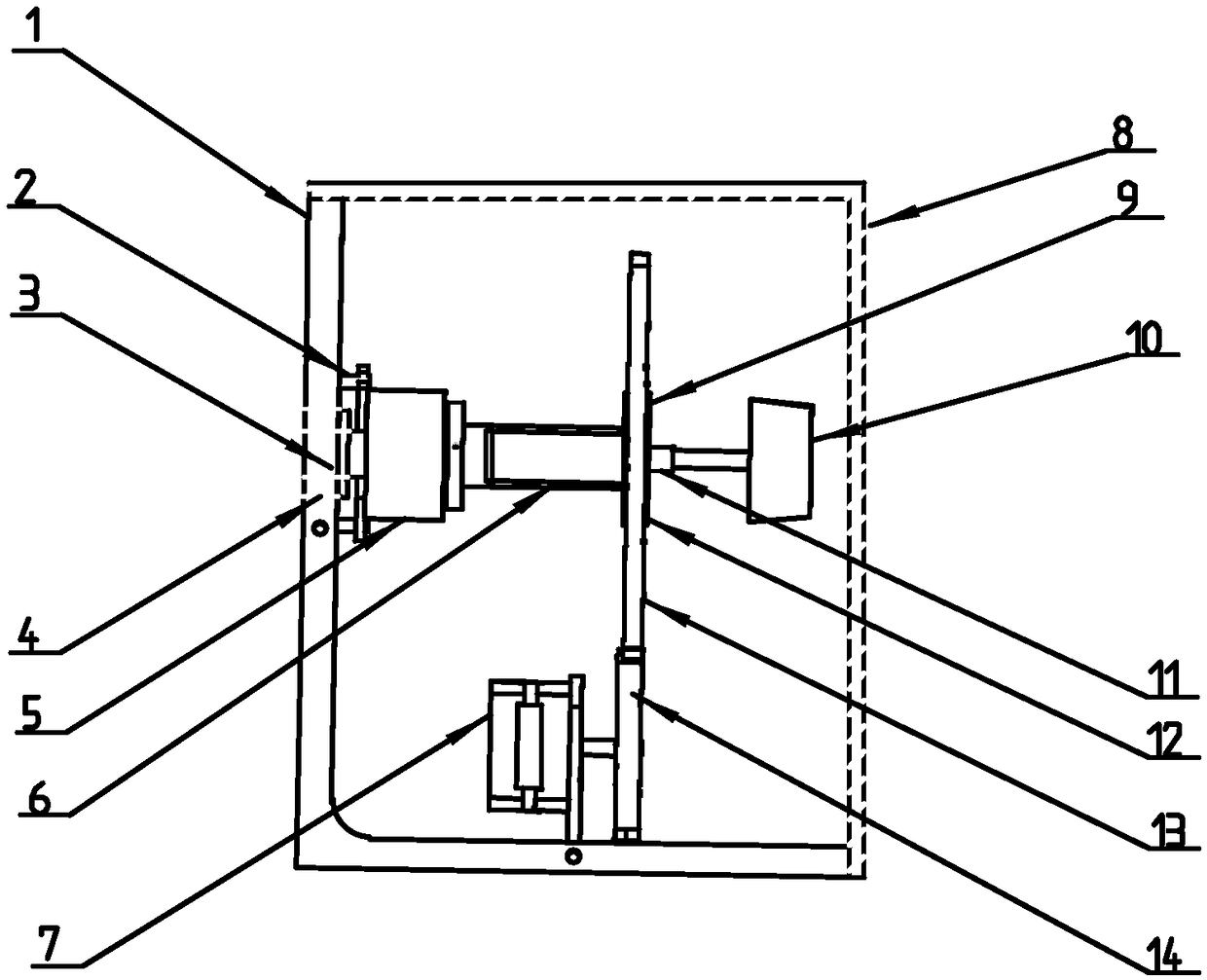

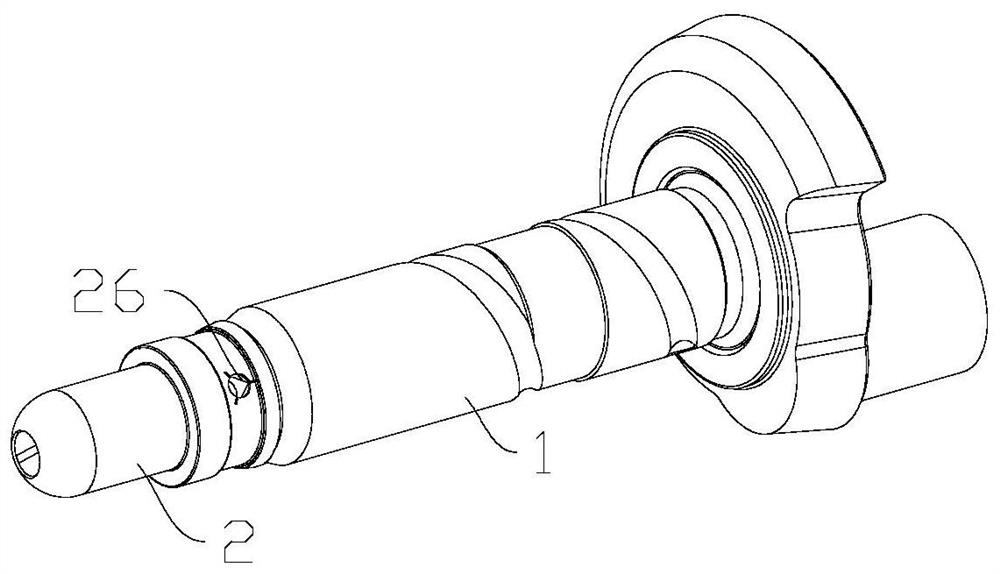

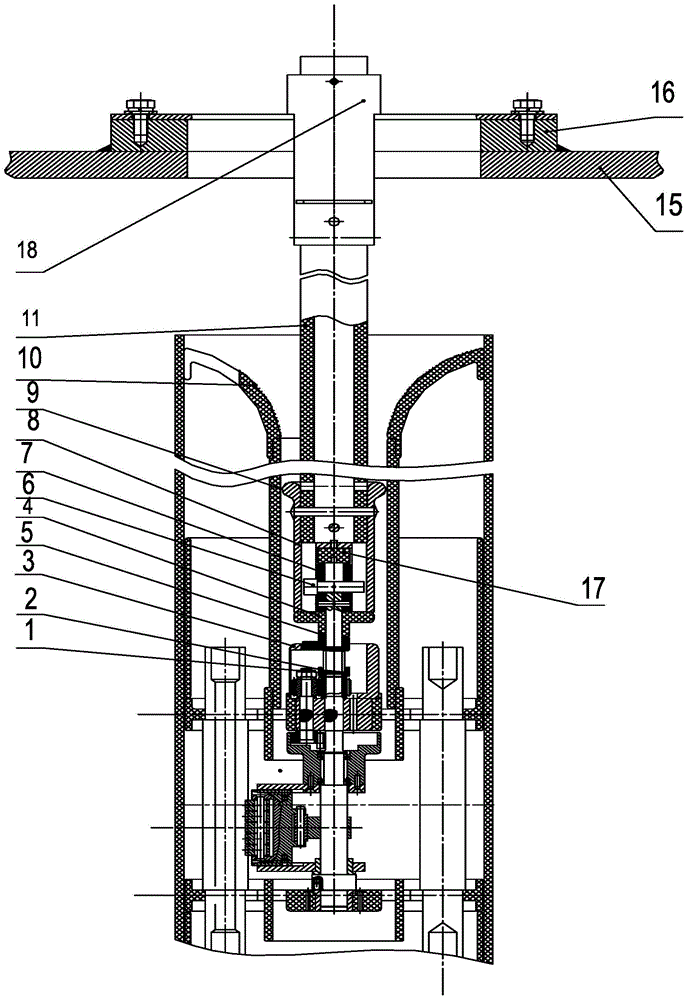

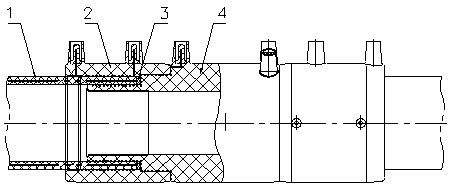

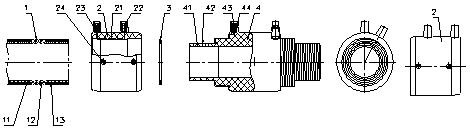

Compressor oil pumping structure, compressor and refrigeration equipment

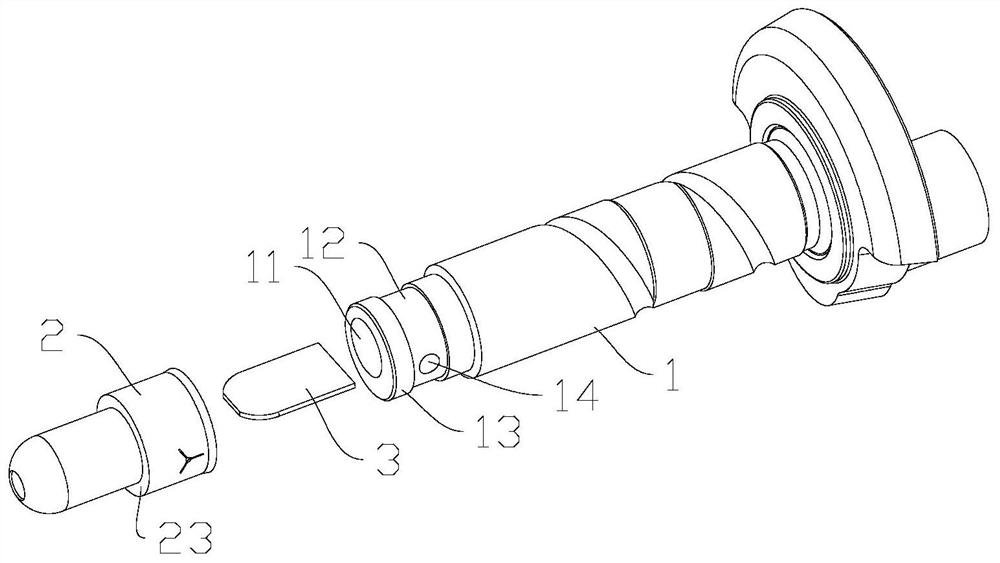

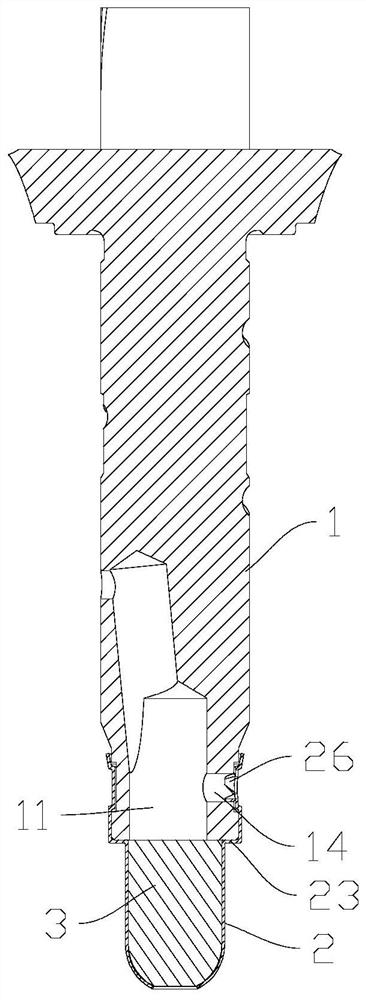

ActiveCN111794970AReliable installation and connectionWon't fall offRotary/oscillating piston pump componentsLiquid fuel engine componentsSuction tubingMechanics

The invention discloses a compressor oil pumping structure, a compressor and refrigeration equipment. The structure comprises a crankshaft, an oil inlet hole is formed in the tail part of the crankshaft; the oil inlet hole is deviated relative to the axis of the crankshaft; a clamping groove is formed in the peripheral surface of the tail of the crankshaft, a clamping boss is formed between the clamping groove and the end face of the tail of the crankshaft, an exhaust through hole is formed in the clamping boss and / or the clamping groove, the exhaust through hole communicates with the oil inlet hole, and the exhaust through hole is located in the side, opposite to the offset direction of the oil inlet hole, of the crankshaft. The structure also comprises an oil suction pipe which is connected to the tail of the crankshaft in a sleeving mode, the oil suction pipe shrinks in the radial direction and is pressed in the clamping groove of the crankshaft, and a clamping structure clamped inthe exhaust through hole is arranged on the oil suction pipe. The structure is simple, the oil suction pipe is reliable in installation and connection and cannot fall off, and relative rotating motioncannot occur; the inner diameter of the oil suction pipe can be maximized. Therefore, the compressor can obtain the maximum oil pumping capacity, the friction pair is safe and reliable, and the service life of the compressor is well guaranteed.

Owner:WANBAO GROUP COMPRESSOR CO LTD

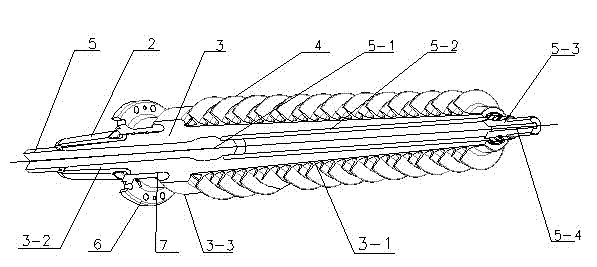

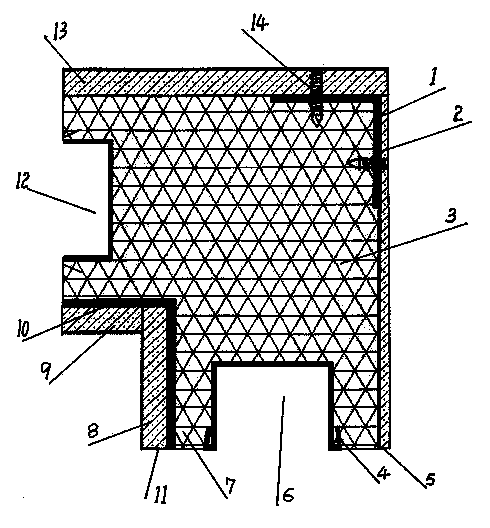

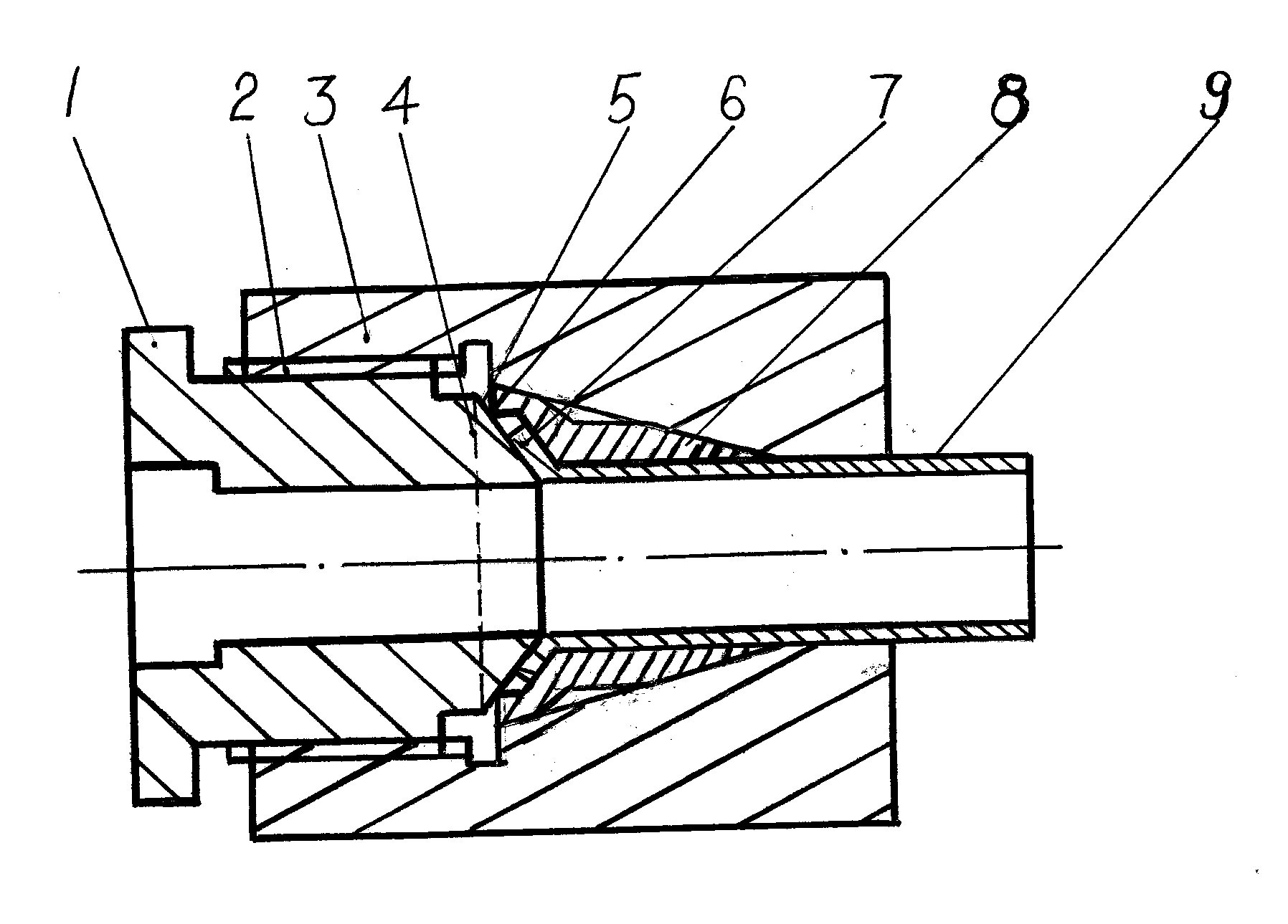

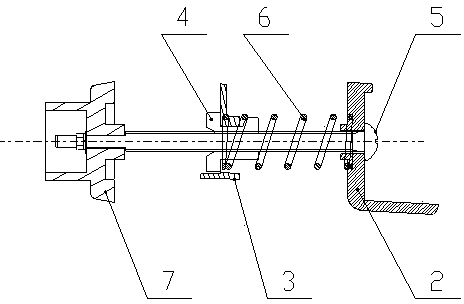

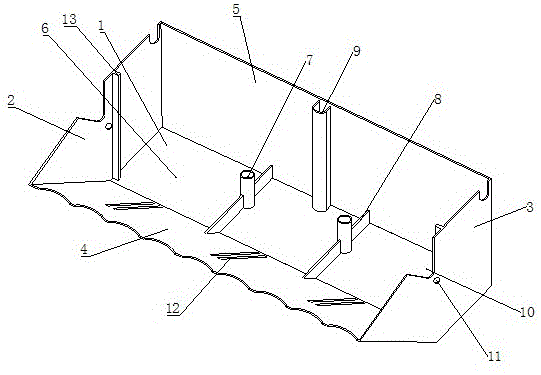

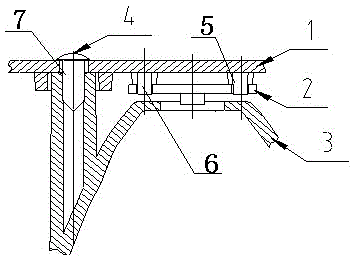

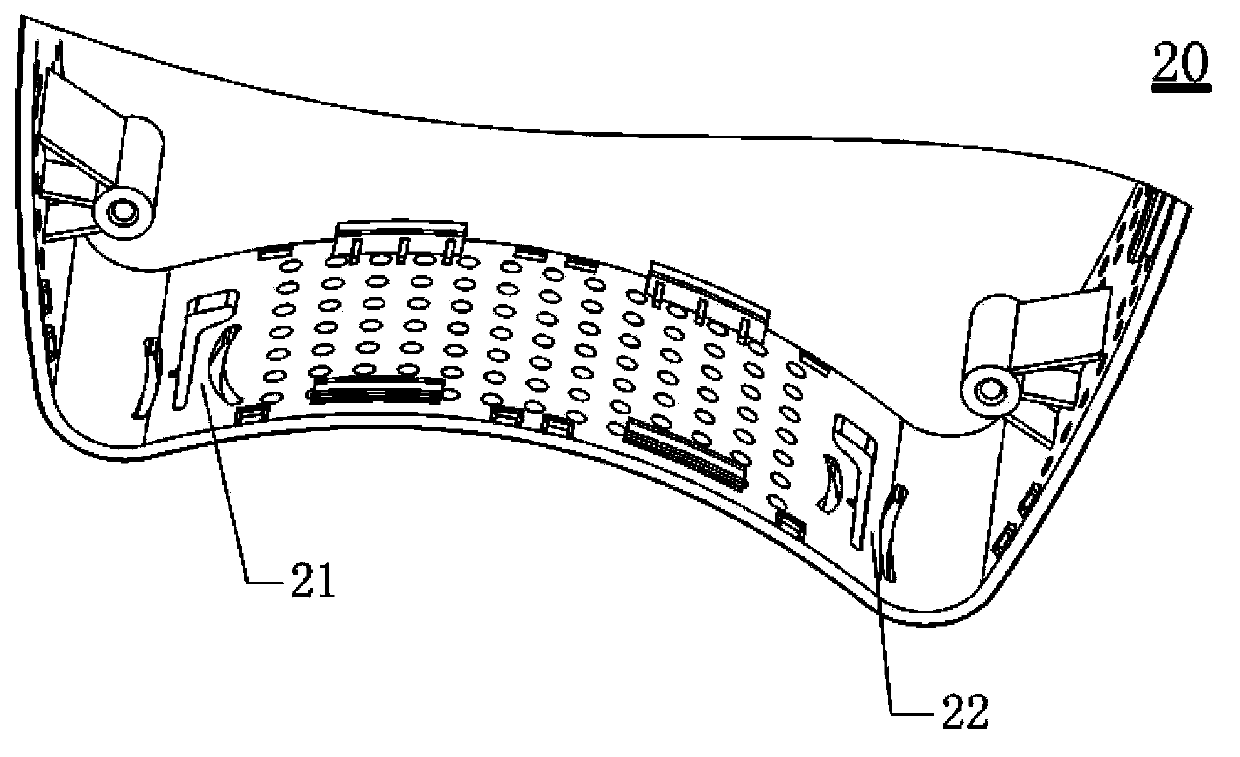

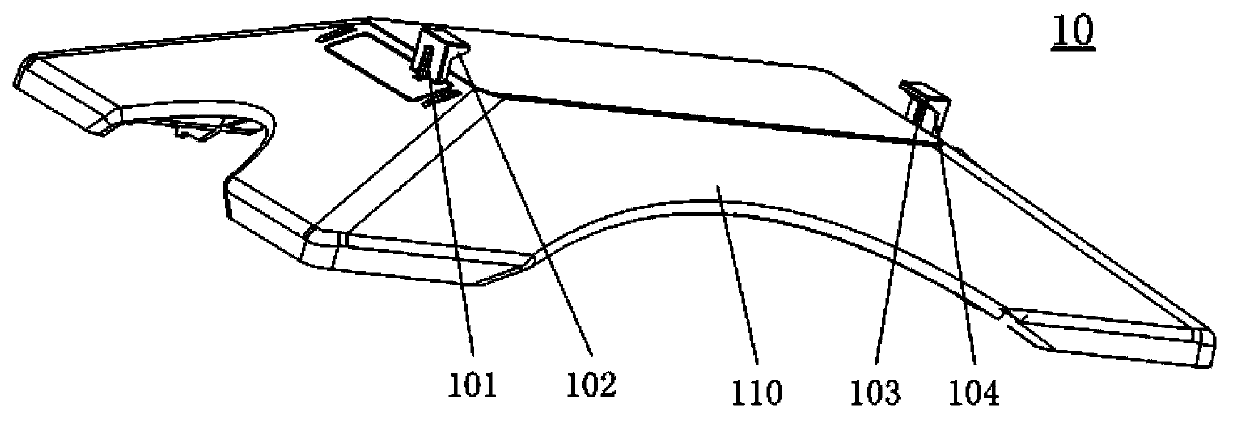

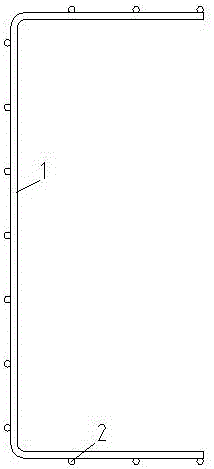

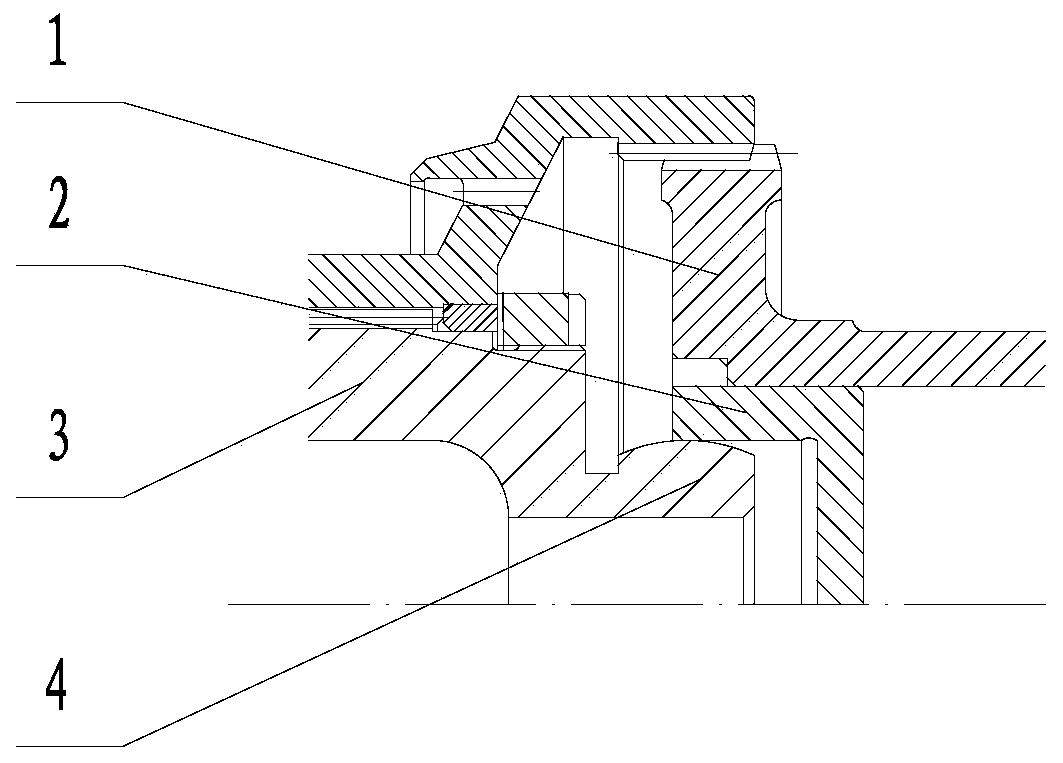

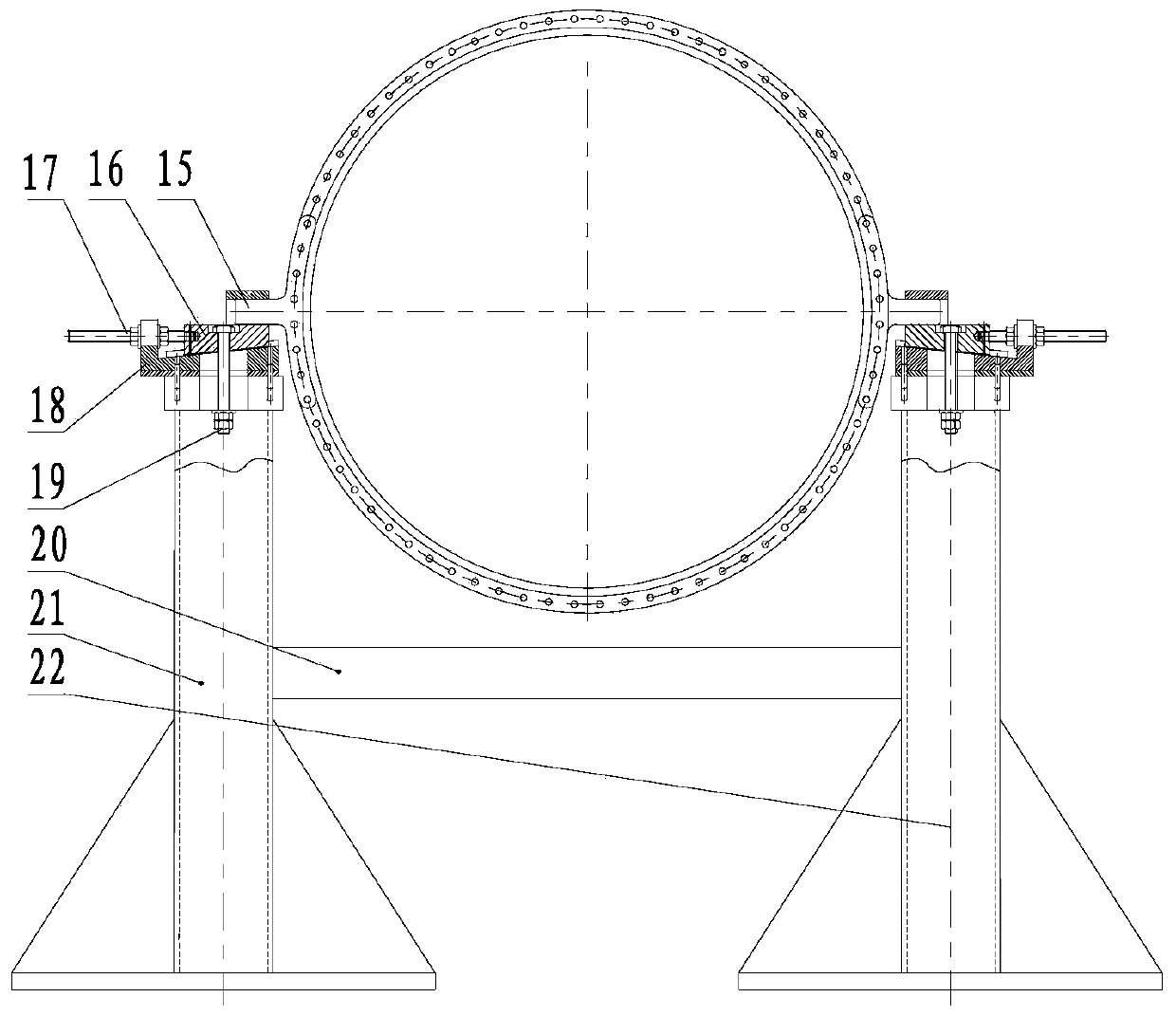

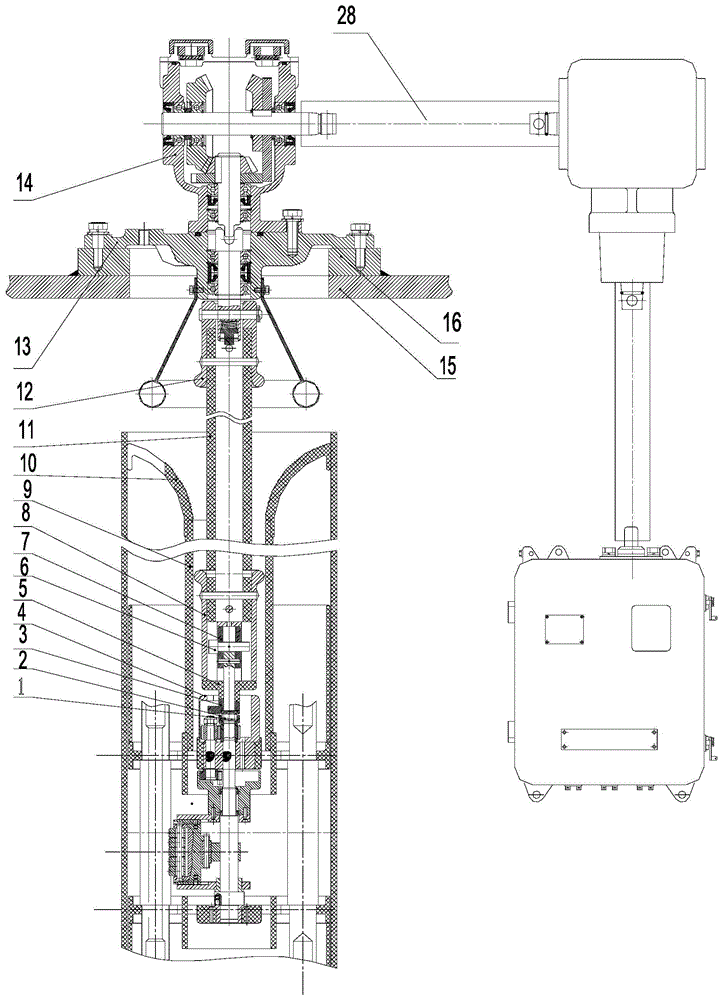

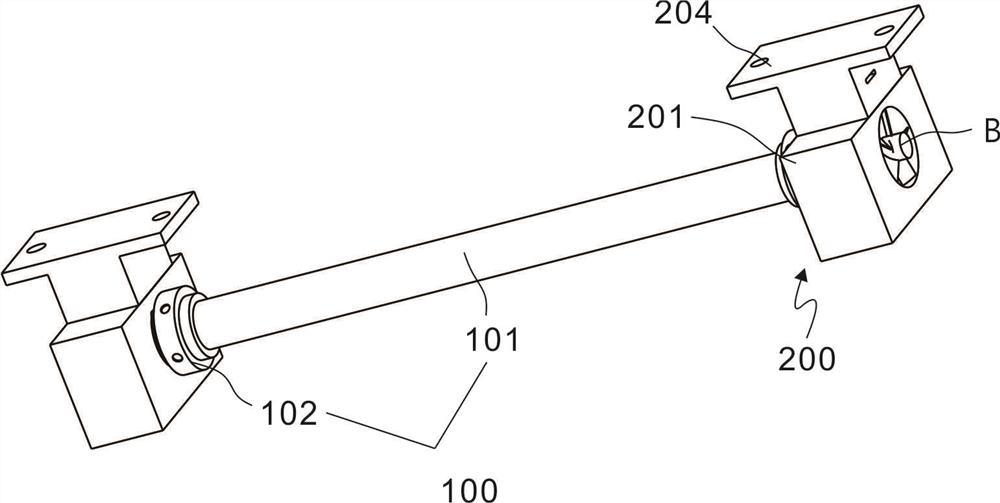

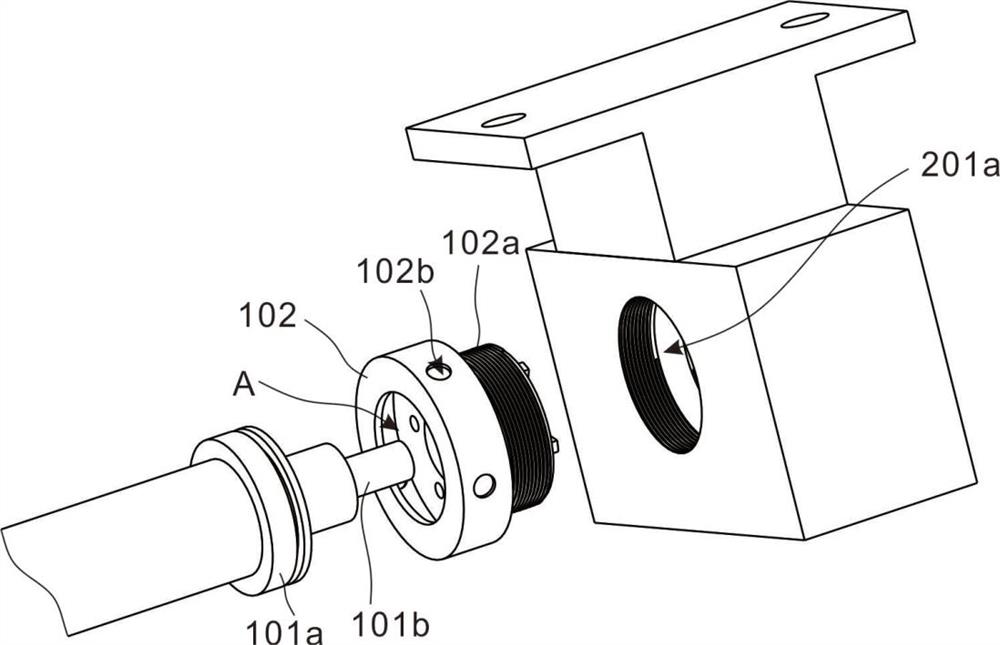

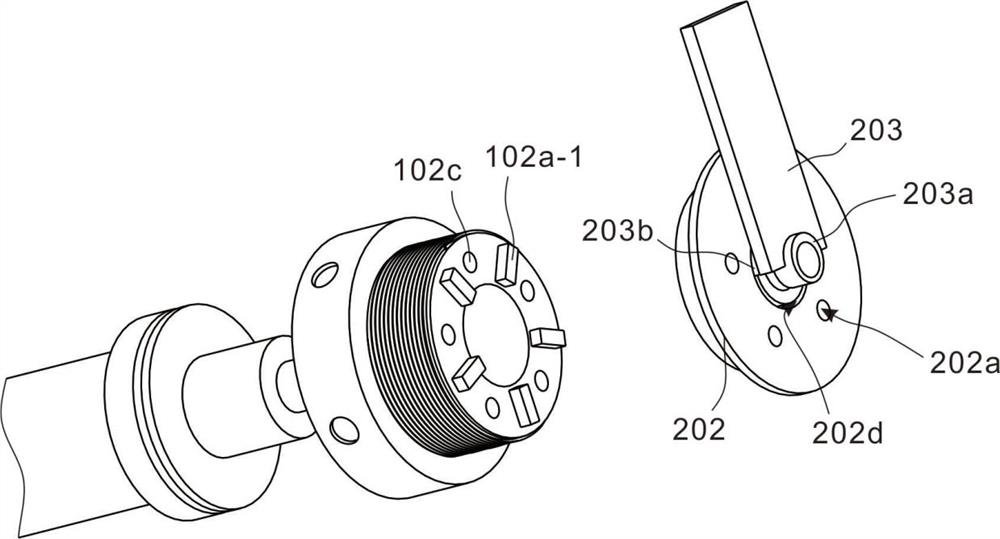

A Bench Installation Method for Performance Test of Aeronautical Axial Flow Compressor

The invention relates to a rack mounting and connection method for test equipment which can be applied to a performance test of an aviation axial flow air compressor. The rack mounting method comprises the step of acquiring a working clearance between an input shaft (1) of an air compressor sample and an output shaft (3) of test equipment air exhaust passage by adopting a pre-installation method before an air compressor is installed. The rack mounting method designs a corresponding front auxiliary supporting structure and an air inlet sealing connection method based on a specific structure type of the air compressor sample.

Owner:AECC SICHUAN GAS TURBINE RES INST

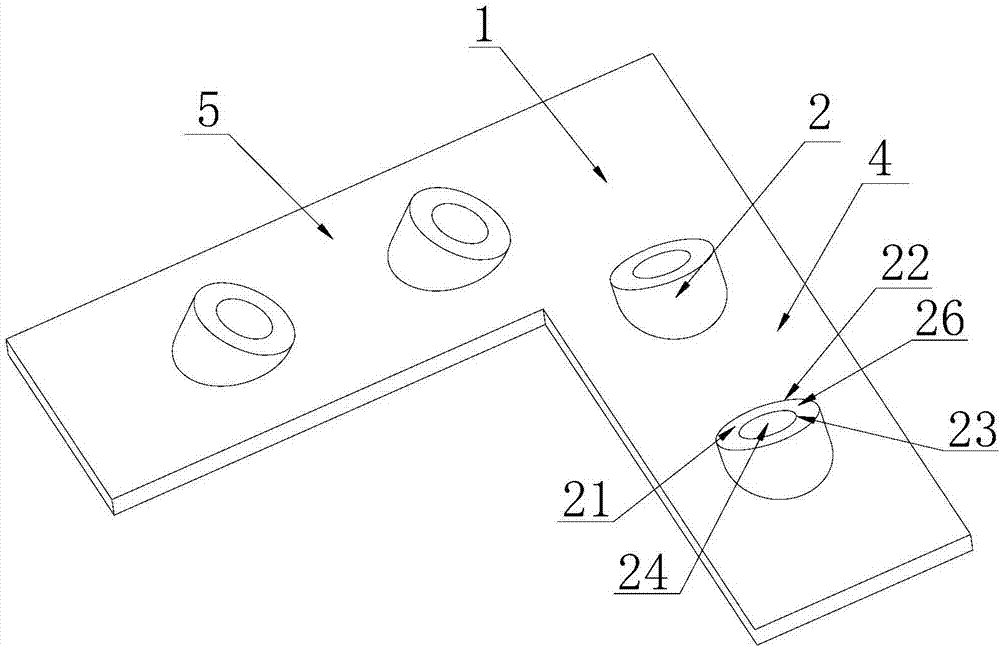

A pipeline connection pipe fitting

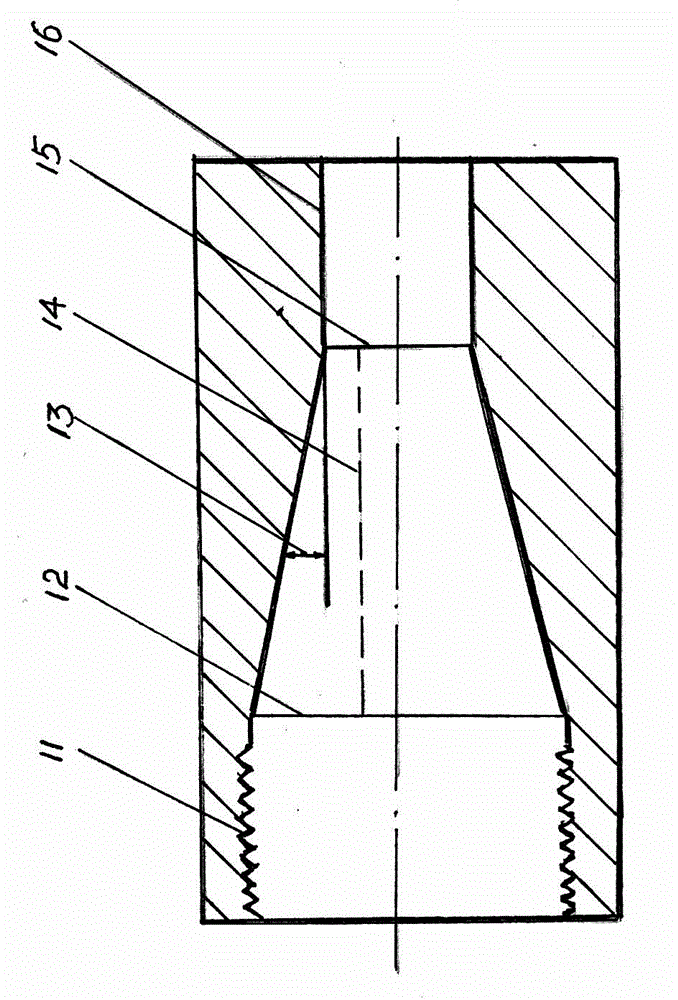

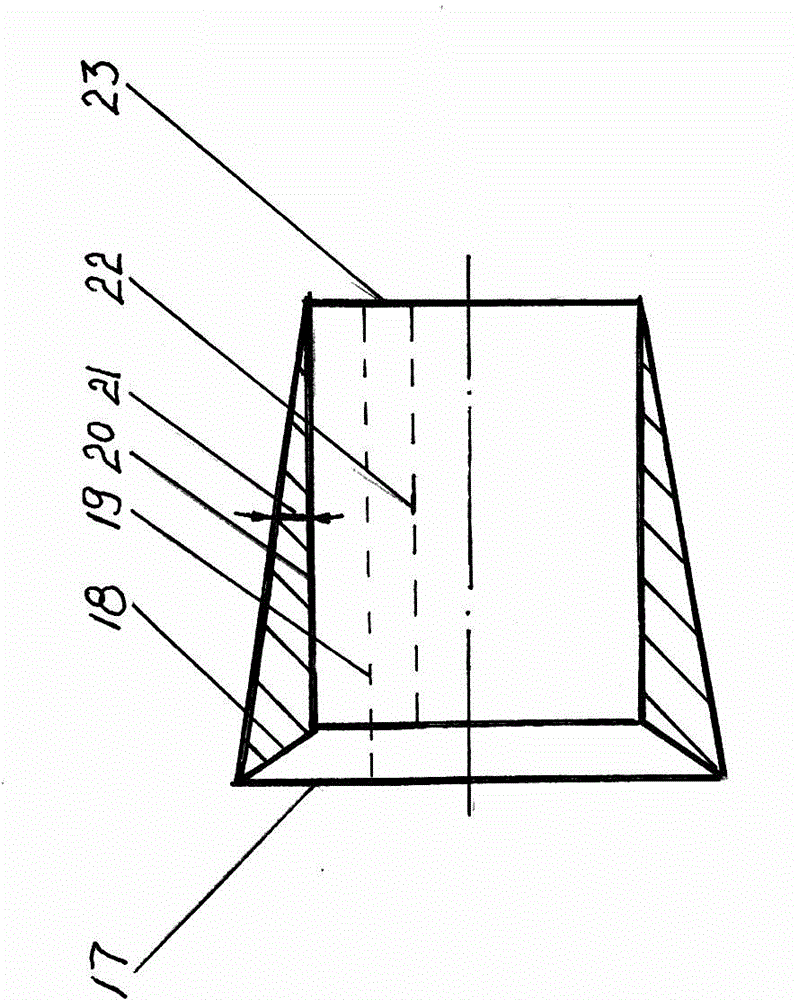

InactiveCN103604013BIncrease the anti-disassembly torqueStrong resistance to disassembly torqueJoints with sealing surfacesPipe fittingOblique angle

Disclosed is a connecting pipe fitting for a pipeline, comprising a nut (3), a connector outer frustum (5) and a connecting pipe bell mouth (7), wherein the nut has an inner tapered bore (6), a tapered sleeve (9) is provided in the nut inner tapered bore (6), the tapered sleeve (9) is a hollow tapered sleeve sheathing hole, a bottom part of the tapered sleeve sheathing hole is provided with a tapered sleeve inner tapered bore (18), a flared groove (24) is provided on the tapered sleeve inner tapered bore (18), a tapered sleeve sheathing hole wall (20) together with a tapered sleeve outer tapering oblique face forms a tapered sleeve tapering oblique angle (21), the connector outer frustum (5) squeezes the bell mouth (7) and squeezes the tapered sleeve inner tapered bore (18), and the tapered sleeve tapering oblique angle (21) was squeezed between the nut inner tapered bore (6) and a connecting pipe (10), sealing the connecting pipe (10) and forming a metallic hard seal between the connector outer frustum (5) and the tapered sleeve inner tapered bore (18), and the connecting pipe bell mouth (7) is squeezed between the connector outer frustum (5) and the flared groove (24), sealing the flared groove. The connecting pipe fitting for a pipeline has the advantages of fast and convenient sealed connection, low requirements in terms of sealing techniques, high sealing performance, being applicable to the connection of pipelines of various materials, and being completely interchangeable with existing connecting nuts.

Owner:孙海潮

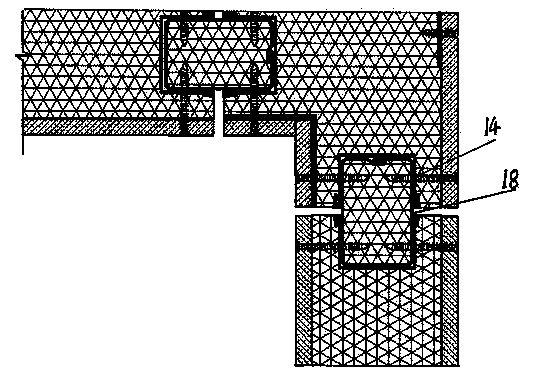

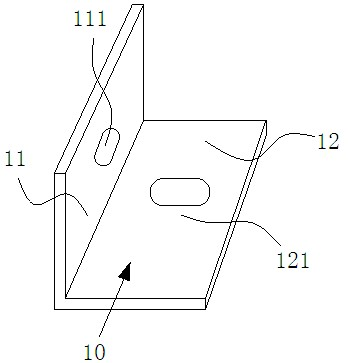

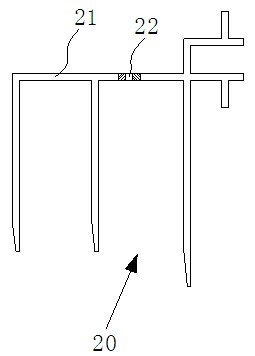

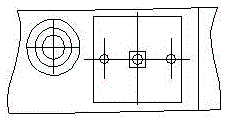

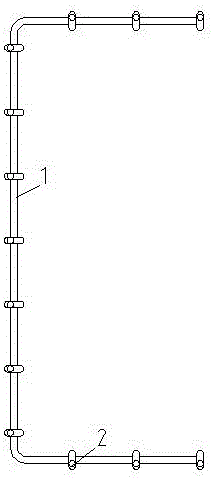

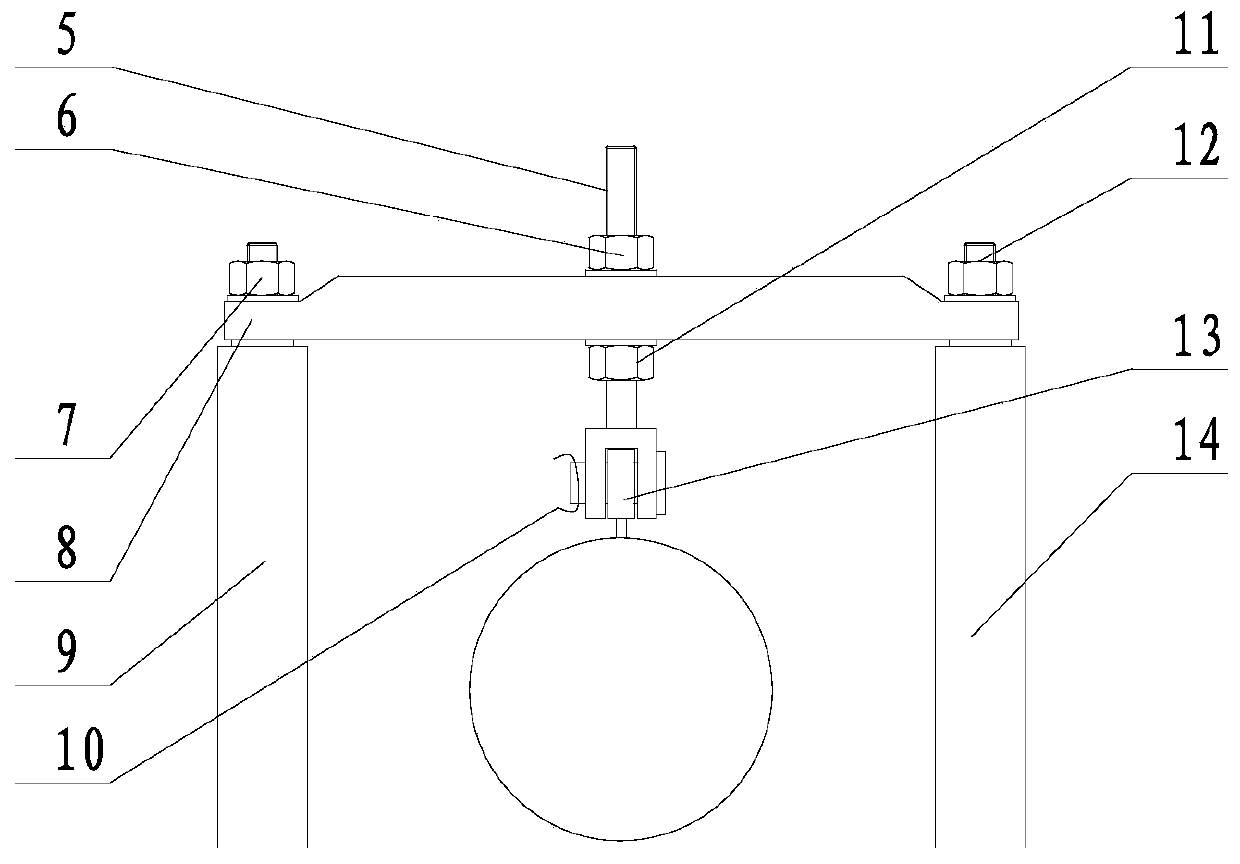

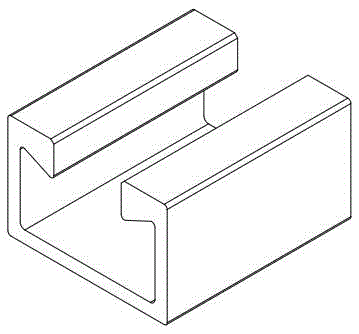

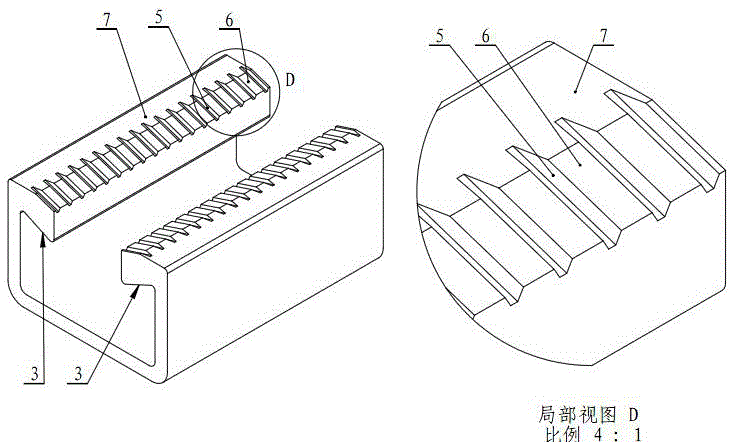

An anti-loose anti-skid channel and its installation and connection device

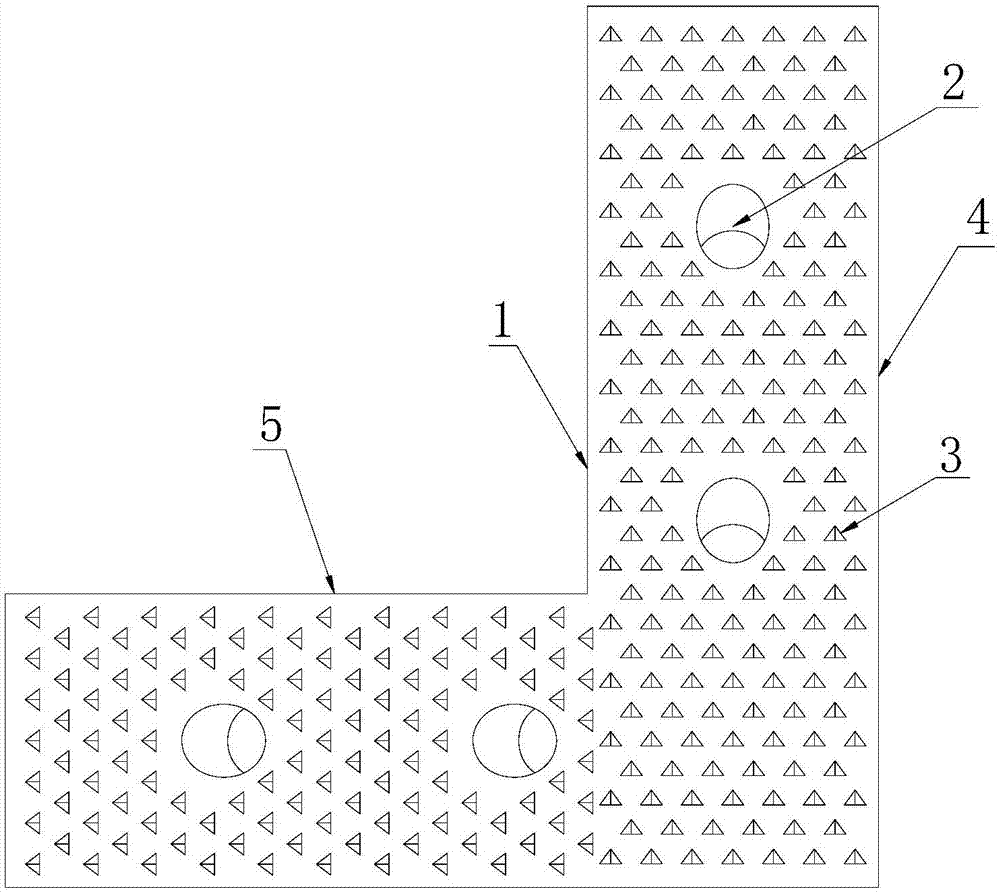

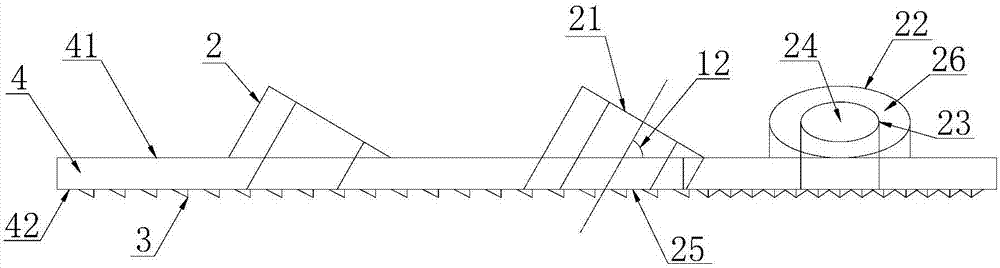

ActiveCN104018584BPrevent looseningEasy to pre-precise positioningTrolley linesBuilding constructionsEngineeringMechanical engineering

The invention discloses a channel with anti-loosening and anti-slip functions and its installation and connection device, which consists of a channel (1), a special bolt for the channel (2), an anti-loosening and anti-slip pad (3), and an installed and connected device. The workpiece (d) is composed. The channel (1) has continuous and evenly distributed serrations 5 on the outer surface of the opening; the pad (3) has serrations 4 matching the outer surface serrations 5 of the channel (1) on both sides of the pad (3). There is a downward clip hook 1; the T-shaped head of the bolt (2) is put into the inner groove of the channel (1), the head 2 hooks the inner hook 3 of the channel (1), and the clamp pad (3) passes through The shank portion of the bolt (two), its tooth surface 4 and the teeth 5 on the outer surface 6 of the groove are engaged, and the clip hook 1 clamps and hooks the head 2 of the bolt (two). The bolt (2) passing through the clip (3) will not move (slide) along the length of the channel under load, which is convenient for the pre-precise positioning of the bolt (2) before the workpiece (4) is installed and during use. The installation connection is more stable and reliable; the whole positioning and locking are stable and reliable, easy to operate, no special tools and accessories are required, and can be reused, with excellent economy.

Owner:成都金和工贸有限公司

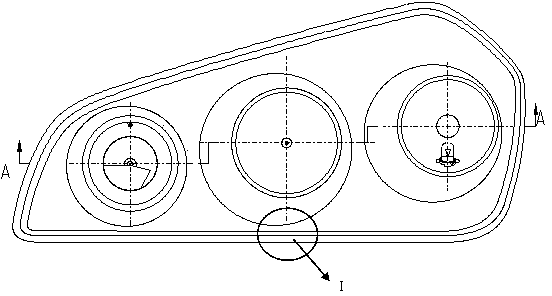

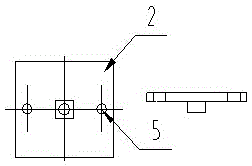

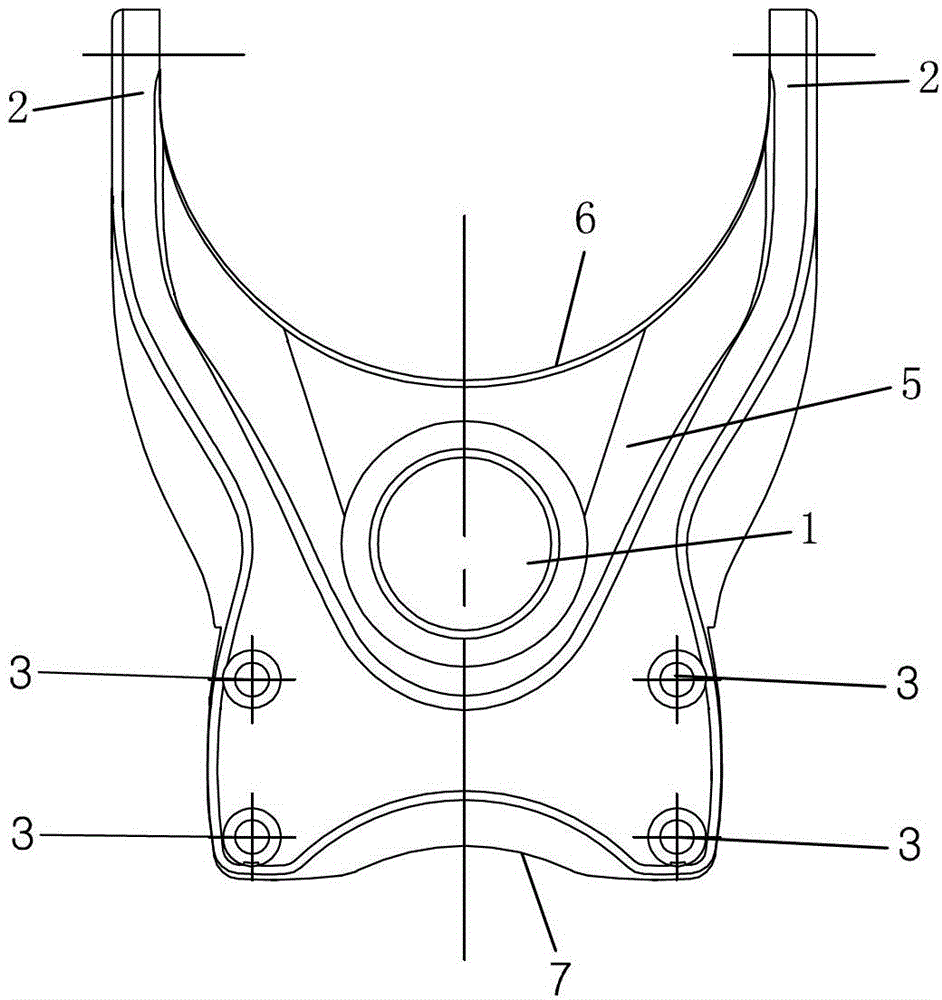

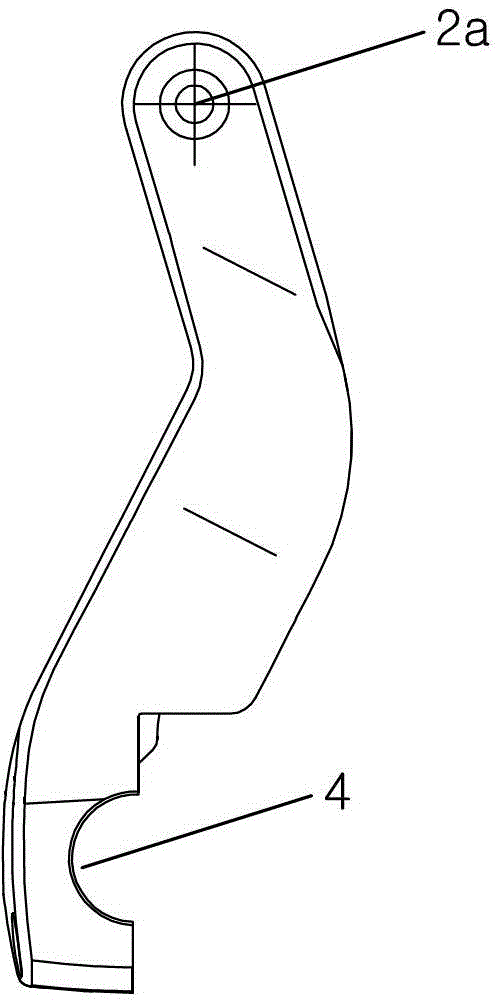

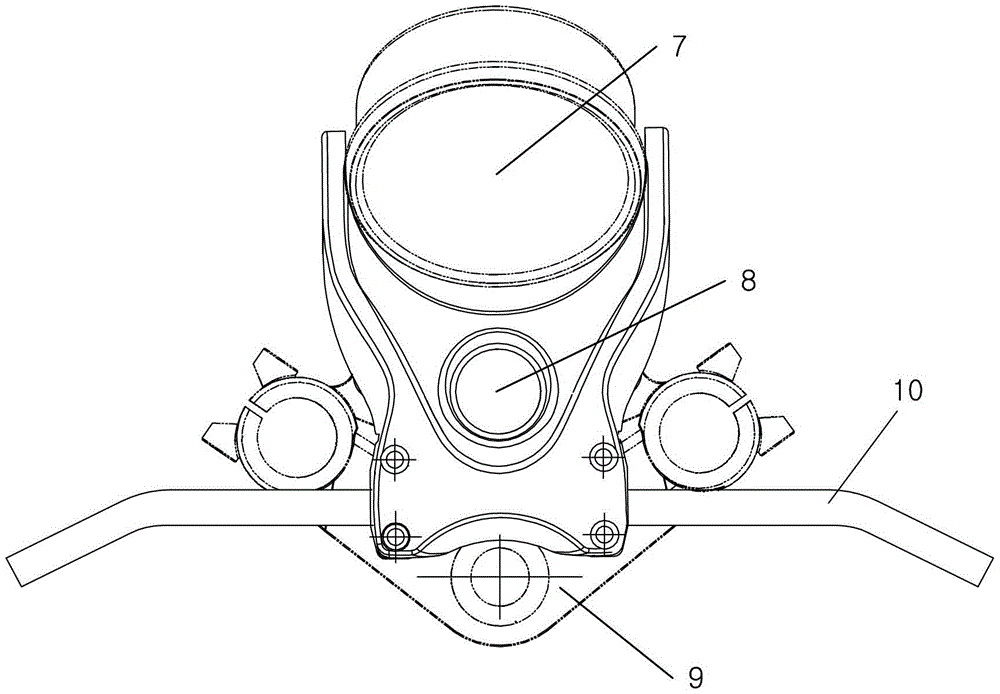

A drum-type off-excitation tap-changer with precise transmission rod installation

ActiveCN104779086BSolve installation problemsReliable operation and installationVariable inductancesVariable transformersCouplingEngineering

The invention relates to a drum-shaped non-excitation tap switch for accurately installing a transmission rod. The drum-shaped non-excitation tap switch comprises a tap switch contact system, a switch self-locking system, a transmission rod coupler system, a transmission rod guide system, a transmission rod connecting system, an end cap installation system, a transmission rod assembling device and a transmission rod locking device. A brand-new breakthrough mode is adopted, the advantages of a traditional non-excitation tap switch are undertaken, the relation of installation requirements of a concentric reducer shaft end, a self-locking device and the tap switch is ingeniously applied, and limiting nails and an auxiliary drill installing device which are simple in process and low in cost are added and used in perfect cooperation in the installation process. The installation problem of the non-excitation tap switch is completely solved, installation and connection are reliable, accurate and easy, the installation dislocation or inaccuracy of a transformer factory is effectively avoided, the repeated installation performance is good, the running safety and reliability of the tap switch can be well ensured, and the possibility of after-overhaul repeated installation dislocation or angle deviation of the tap switch is completely eliminated.

Owner:贵州辰廷电力设备制造有限公司

A detachable lighting tube with convenient fastening connection

ActiveCN113775965BReduce the temperatureSafe installationLighting support devicesElongate light sourcesEngineeringMechanical engineering

The invention discloses a detachable lighting lamp tube which is conveniently fastened and connected, which comprises a lighting assembly, the lighting assembly includes a lamp tube and a connecting cover, terminals are arranged at both ends of the lamp tube, and conductive heads are vertically arranged on the terminals , the connecting cover is sleeved on both ends of the lamp tube, the connecting cover is embedded on the outer wall of the terminal and connected to the terminal in rotation; and a barrier sleeve, the lamp holder is provided with a cavity, the barrier sleeve is installed in the cavity, and the conductive head is inserted into the cavity through the connection cover and connected with the barrier sleeve; the present invention adds A fastening device is provided to match the lamp holder. The outer wall is made of insulating material, which makes the installation safer, avoids direct contact with the internal wires during installation, reduces the risk of leakage, and makes the installation and connection more reliable. It has the function of ventilation and heat dissipation, and reduces electrical conductivity The temperature of the wire can increase the service life.

Owner:江苏烨明光电有限公司

Multifunctional ignition switch cover

Owner:力帆科技(集团)股份有限公司

Construction Method of Setting Steel Corbel on Concrete Frame Column

InactiveCN103572973BEasy to pourImprove vibrationBuilding material handlingRebarUltimate tensile strength

The invention relates to a construction method for arranging a steel corbel on a concrete frame column. The construction method comprises the steps of assembling steel reinforcements to form a steel reinforcement framework, and fixing at least four pre-cast screws on at least one face of the steel reinforcement framework according to the designed elevation, wherein one end of each pre-cast screw and the steel reinforcements in the steel reinforcement framework are in point welding to be fixed, and the other end of each pre-cast screw is exposed out of the steel reinforcement framework; installing a formwork on the outer side of the steel reinforcement framework, wherein the portions, exposed out of the formwork, of the pre-cast screws are protected by being wound with adhesive plasters; pouring concrete in the steel reinforcement framework; after the concrete reaches the design strength, disassembling the formwork to form the concrete frame column; installing the steel corbel on the concrete frame column, wherein the steel corbel is provided with a plurality of transverse adjustable bolt holes, and the steel corbel is fixed on the pre-cast screws through bolt holes in an adjustable mode.

Owner:JIANGSU XIANGSEN CONSTR ENG

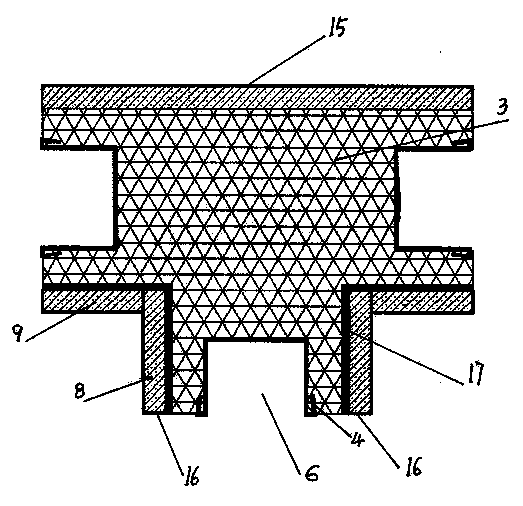

A double-sided electric fusion pipe fitting for composite pipe and its connection method

ActiveCN106641545BReliable installation and connectionEasy to install and connectPipe connection arrangementsThermoplasticPipe fitting

The invention relates to a double-faced electric smelting pipe fitting composed of a metal reinforced material layer serving as the middle and thermoplastic plastic composite layers serving as inner and outer layers and used for steel-plastic composite pressure pipeline and a connecting method. When a composite pipe interlayer is made of metal, the electric smelting pipe fitting in a casing pipe is firstly arranged on the outer surface of the composite pipe end in a sleeving mode, then the electric smelting pipe fitting outside the casing pipe is sleeved with a gasket and is inserted into a composite pipe hole, the step end face of the electric smelting pipe fitting outside the casing pipe is fit with the step end face of the electric smelting pipe fitting in the casing pipe, the composite pipe and a pipe network are fixed, an electric smelting welder is turned on, the electric smelting pipe fitting in the casing pipe and the outer surface of the composite pipe are molten integrally, whether an outward protruding state and size of a welding measurement core meet the requirements or not are detected through the welding measurement core, then the electric smelting pipe fitting outside the casing pipe is turned on and is molten with the inner surface of the composite pipe and the electric smelting pipe fitting in the casing pipe, and finally whether the outward protruding state and size of the welding measurement core meet the design requirements or not are detected through the welding measurement core.

Owner:ZHEJIANG SHUANGLIN PLASTIC MACHINERY

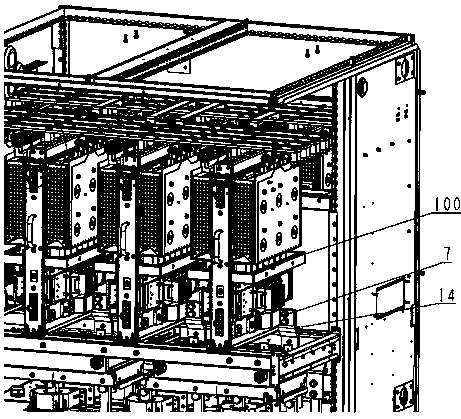

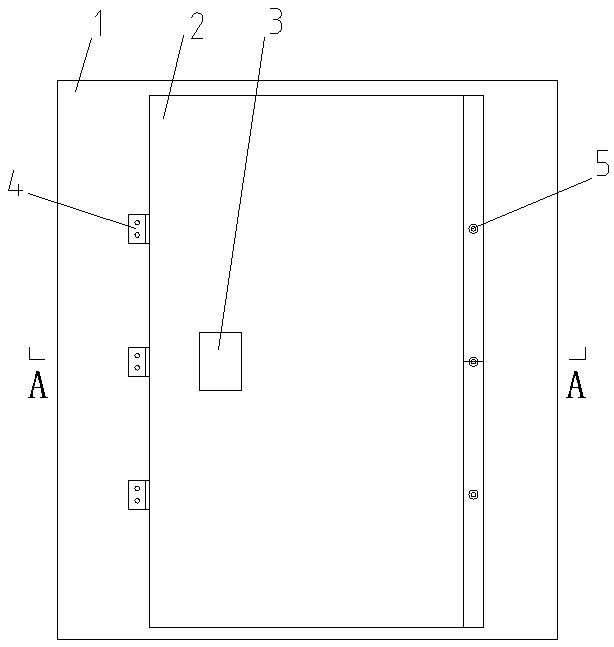

Pressure releasing passage of switch cabinet

PendingCN108711742AReduce opening resistanceEasy to holdSubstation/switching arrangement casingsEngineeringSwitchgear

The invention relates to a pressure releasing passage of a switch cabinet. A pressure releasing cover covers a pressure releasing window in a top plate of a cabinet body of the switch cabinet, one side of the pressure releasing cover is fixedly connected with the top plate of the cabinet body by a plastic screw, the other side of the pressure releasing cover is hinged with the top plate of the cabinet body via a hinge, a groove s formed in a top plate of the pressure releasing cover and is sunken, two side walls of the groove incline towards a downward and outward direction along a vertical central line of the groove so that the two side walls of the groove form a slanted inclined opening, through holes are formed in the two side walls of the groove, and the two sides of the pressure releasing cover are connected to the top plate of the cabinet body of the switch cabinet by the plastic screw and the hinge. The opening resistance of the pressure releasing cover can be reduced, the pressure releasing cover rotates and is turned over along the hinge after being opened and cannot be ripped off and lost, and the pressure releasing passage is reliable to install and connect; the groove is formed in the top plate of the pressure releasing cover and is sunken, the two side walls of the groove incline to form the slanted inclined opening, an edge of the groove is convenient to grasp, the carrying and installation operation is convenient, the through holes in the two side walls of the groove form auxiliary pressure releasing holes, and the pressure releasing effect is improved.

Owner:ZHENJIANG SCHNEIDER ELECTRIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com