Steel mesh bridge

A bridge and steel mesh technology, applied in the direction of electrical components, etc., can solve the problems of packaging and handling, inconvenient installation and transportation, difficult bolt connection and fastening, long construction time, etc. short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

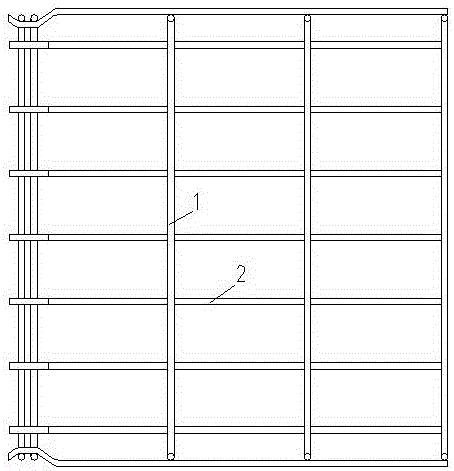

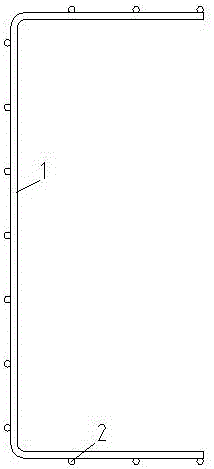

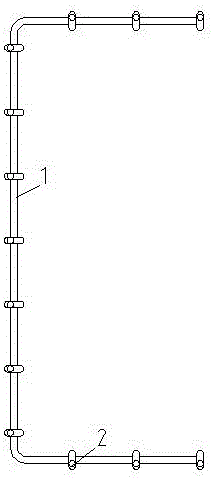

[0018] As shown in the figure, a steel mesh bridge includes several U-shaped beams 1, and several longitudinal ribs 2 fixedly connected to the U-shaped beams 1, and the connection point between the U-shaped beams 1 and the longitudinal ribs 2 is located inside the longitudinal ribs 2; At least one end of the steel mesh bridge is the head end with two U-shaped beams 1 that are relatively close to each other. A section of longitudinal rib 2 connected to the two U-shaped beams 1 at the head end bends inward to form a groove so that the two U-shaped beams 1 at the head end The U-shaped beam 1 is in the groove of the longitudinal rib 2, that is, the connection point between the two U-shaped beams 1 at the head end and the groove section of the longitudinal rib 2 is located outside the longitudinal rib 2; when connecting with the conventional steel mesh bridge, the groove of the longitudinal rib 2 The section is located inside the U-shaped beam 3 at the end of the conventional bridge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com