Giant magnetostrictive drive grinding machine

A giant magnetostriction and grinding machine technology, which is applied in the direction of grinding frame, grinding drive device, grinding machine tool parts, etc., can solve the efficiency and accuracy requirements of mass production and grinding, and the grinding accuracy of small-sized workpieces Unable to guarantee, health hazards and other problems, to achieve the effect of good sealing protection, high quality grinding and good precision control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

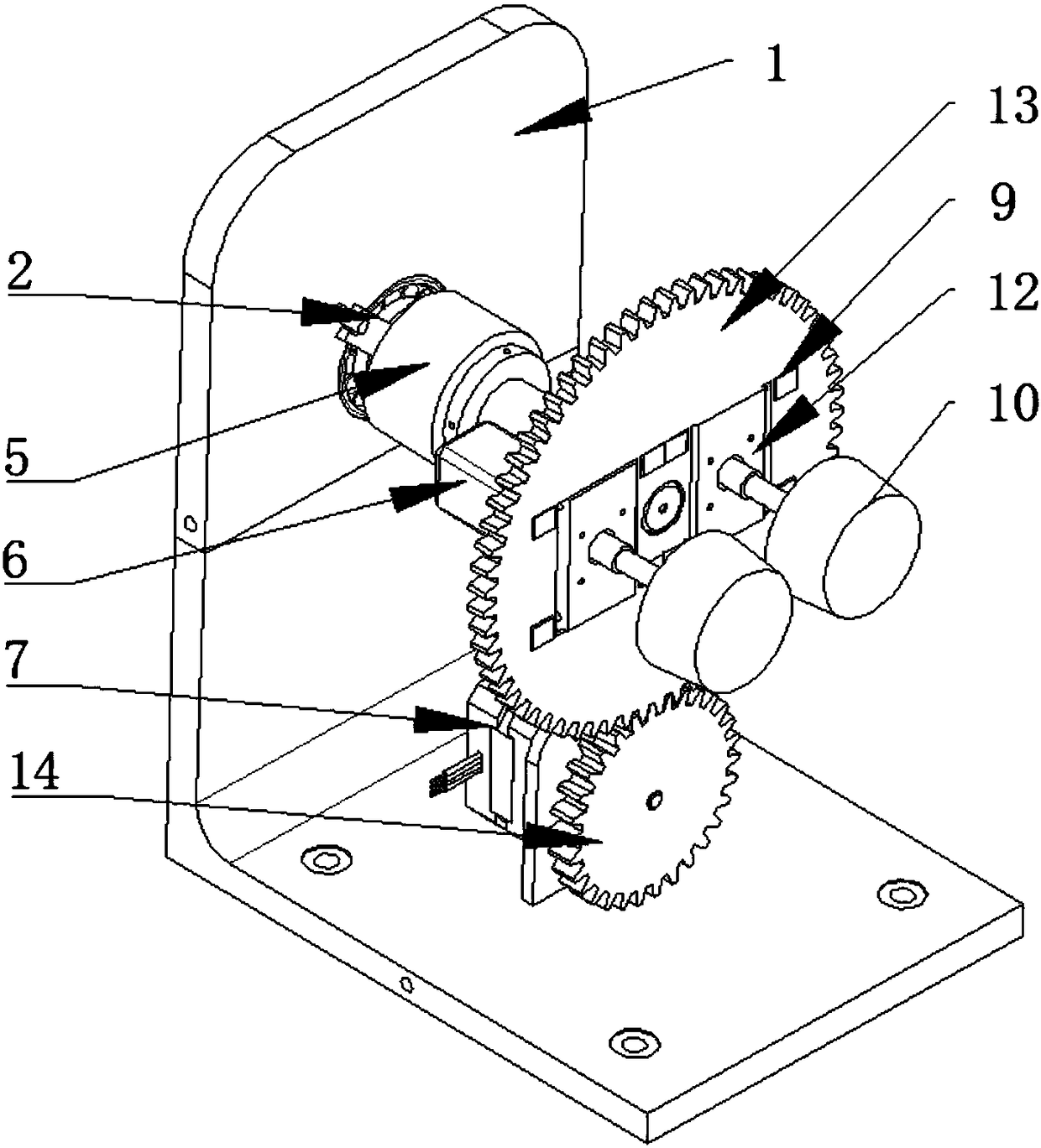

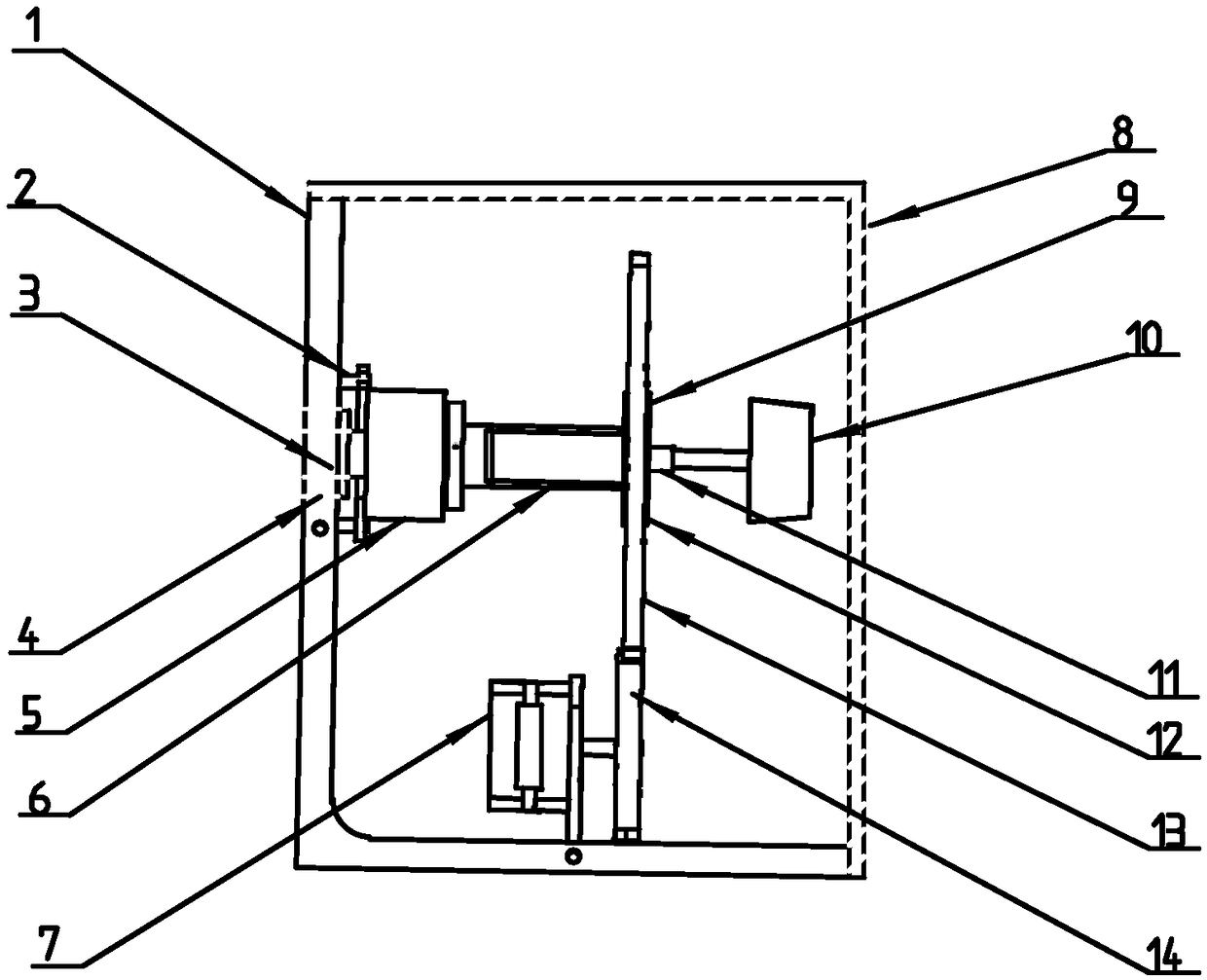

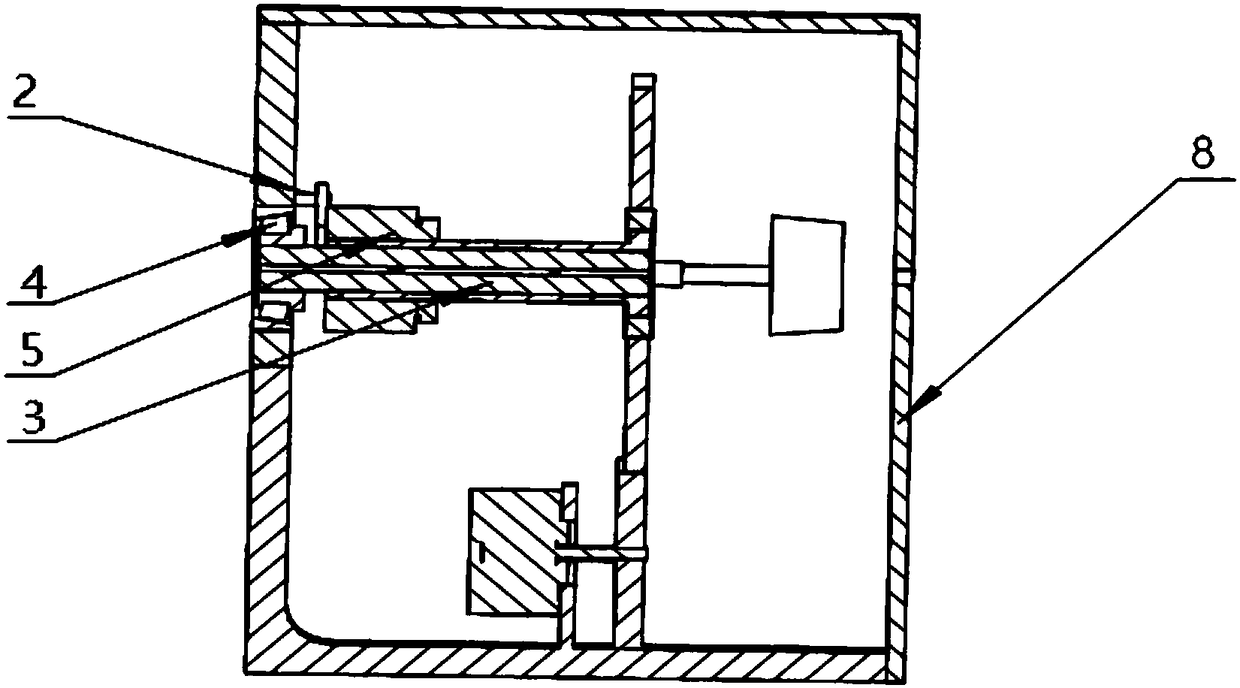

[0029] Such as figure 1 , 2 Shown in and 3, a kind of giant magnetostrictive driving grinding machine comprises at least one pair of grinding head 10, fixed bracket 1, the electric slip ring fixed bracket 2 that is contained in described fixed bracket 1 inner side, is fixed on described by bearing 4 The hollow shaft 3 on the fixed bracket 1, the stator part is fixedly installed on the electric slip ring 5 and the control system on the electric slip ring fixed bracket 2, the fixed bracket 1 is L-shaped, and also includes Removing the connected grinding machine shell 8 can ensure the safety performance of the grinding machine during high-speed operation. The rotor part of the electric slip ring 5 is sleeved on the hollow shaft 3 and connected to the fixed disk 13. The fixed disk 13 is installed on the hollow shaft 3 at the end far away from the electric slip ring 5, and is connected with the stepping motor 7 and the transmission mechanism, the transmission mechanism is a gear t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com