Solid insulated sleeve with inserting type connection

A solid insulation, plug-in technology, applied in cable joints, switchgear settings, switchgear and other directions, can solve the problems of increased substation construction costs, complex cable terminal structure, complex processing technology, etc., to achieve simple installation and connection, meet dynamic Thermal stability, the effect of simplifying the wiring of the power supply system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

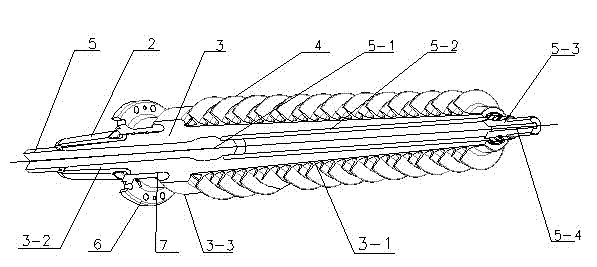

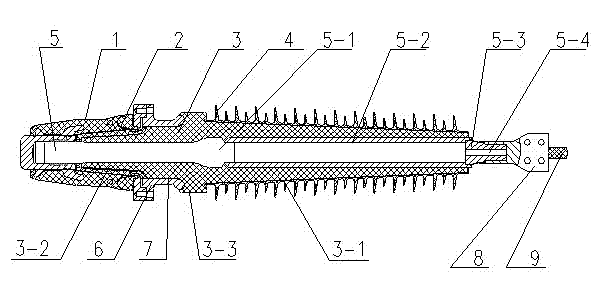

[0029] Specific embodiments of the present invention are provided below in conjunction with the accompanying drawings.

[0030] As shown in the accompanying drawings, the present invention includes a solid insulating layer 3 and a conductive mandrel 5, which is processed by a conductive rod 5-1, a terminal head 5-3 and a pure copper tube processed by adopting a pure copper rod The conductive tube 5-2 is welded by argon arc to carry the working current. The outer surface is shot blasted to increase the adhesion. The solid insulating layer 3 is formed by heating and curing the glass fiber of epoxy resin. The solid insulating layer 3 is used as the main insulating layer. After turning, the large tapered surface 3-1 of the casing and the casing Small cone surface 3-2, the taper of casing large cone surface 3-1 is 3 to 5 degrees, the taper of casing small cone surface 3-2 is 8 to 12 degrees, casing large cone surface 3-1 and casing Casing stepped boss 3-3 is processed at the trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com