A Bench Installation Method for Performance Test of Aeronautical Axial Flow Compressor

A technology for axial flow compressors and installation methods, which is applied in the direction of engine testing, machine/structural component testing, and measuring devices, and can solve the problem that key connection parameters are not effectively controlled, affecting the test work of compressor test pieces, external machines, etc. Problems such as box or bearing vibration, to meet the requirements of safety and test data validity, good promotion and application value, and eliminate rotor friction or eccentric wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below by means of specific embodiments:

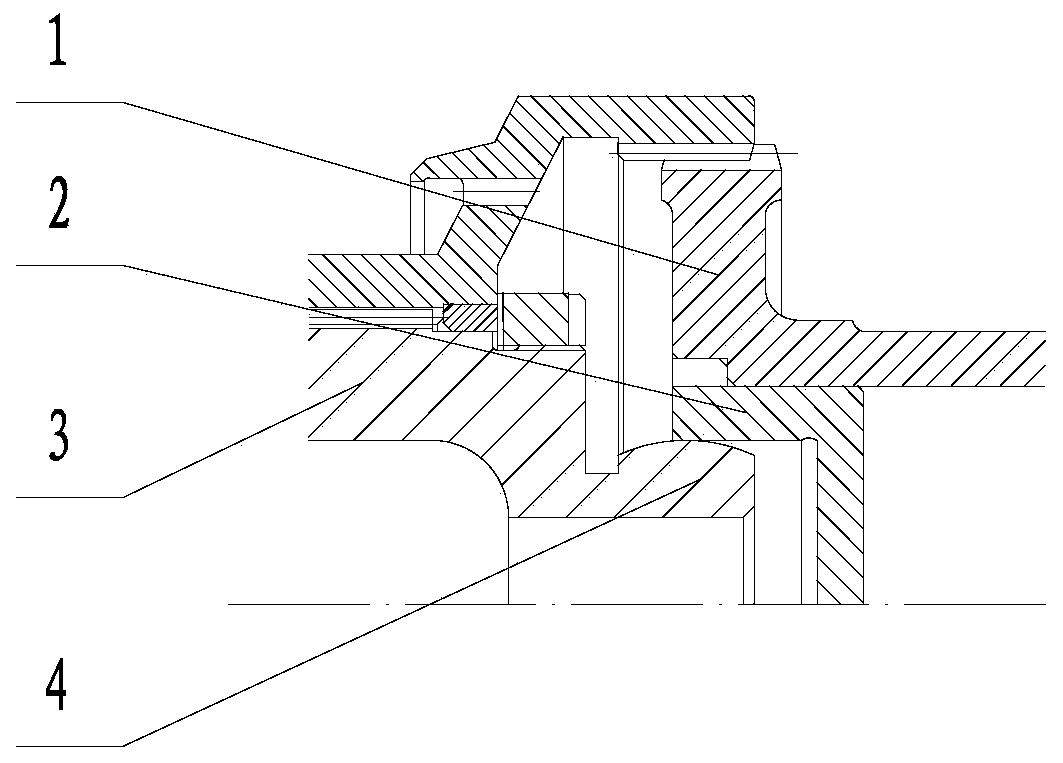

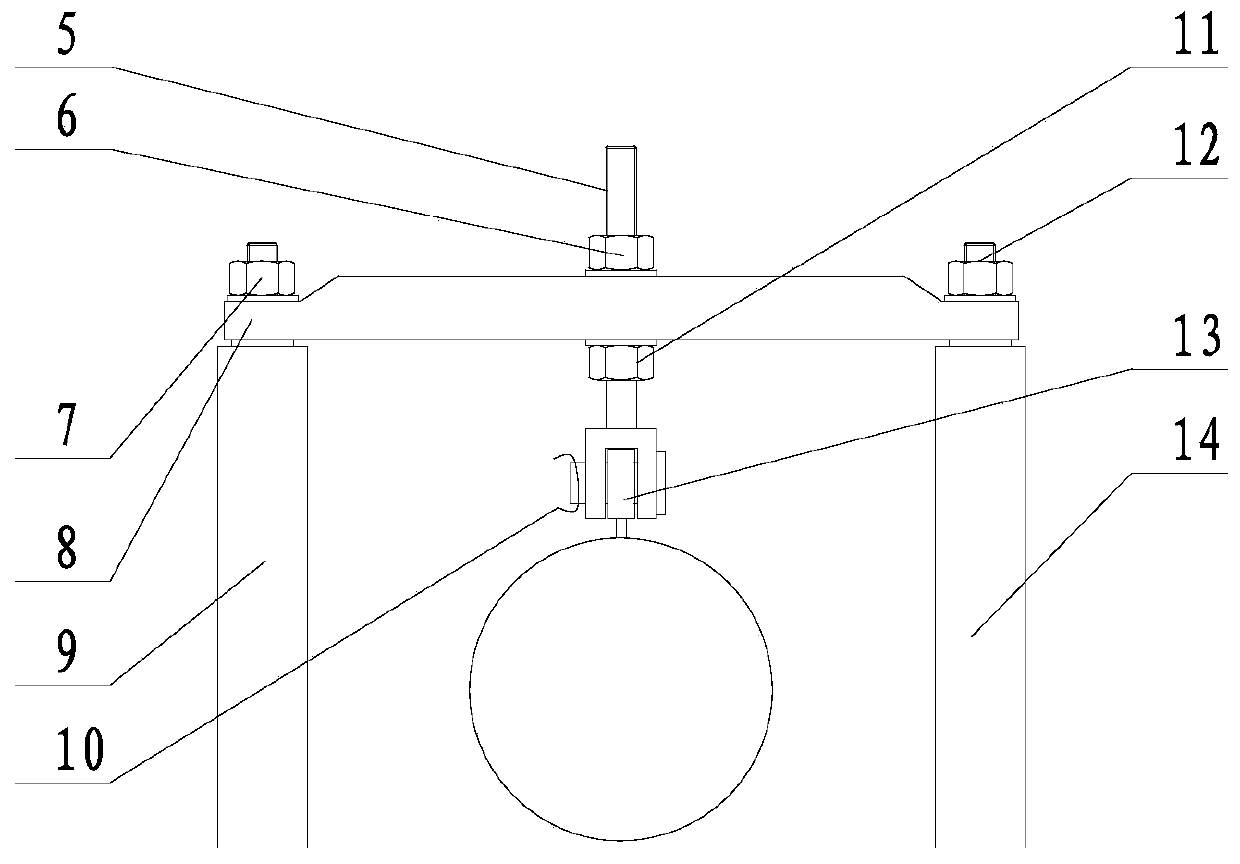

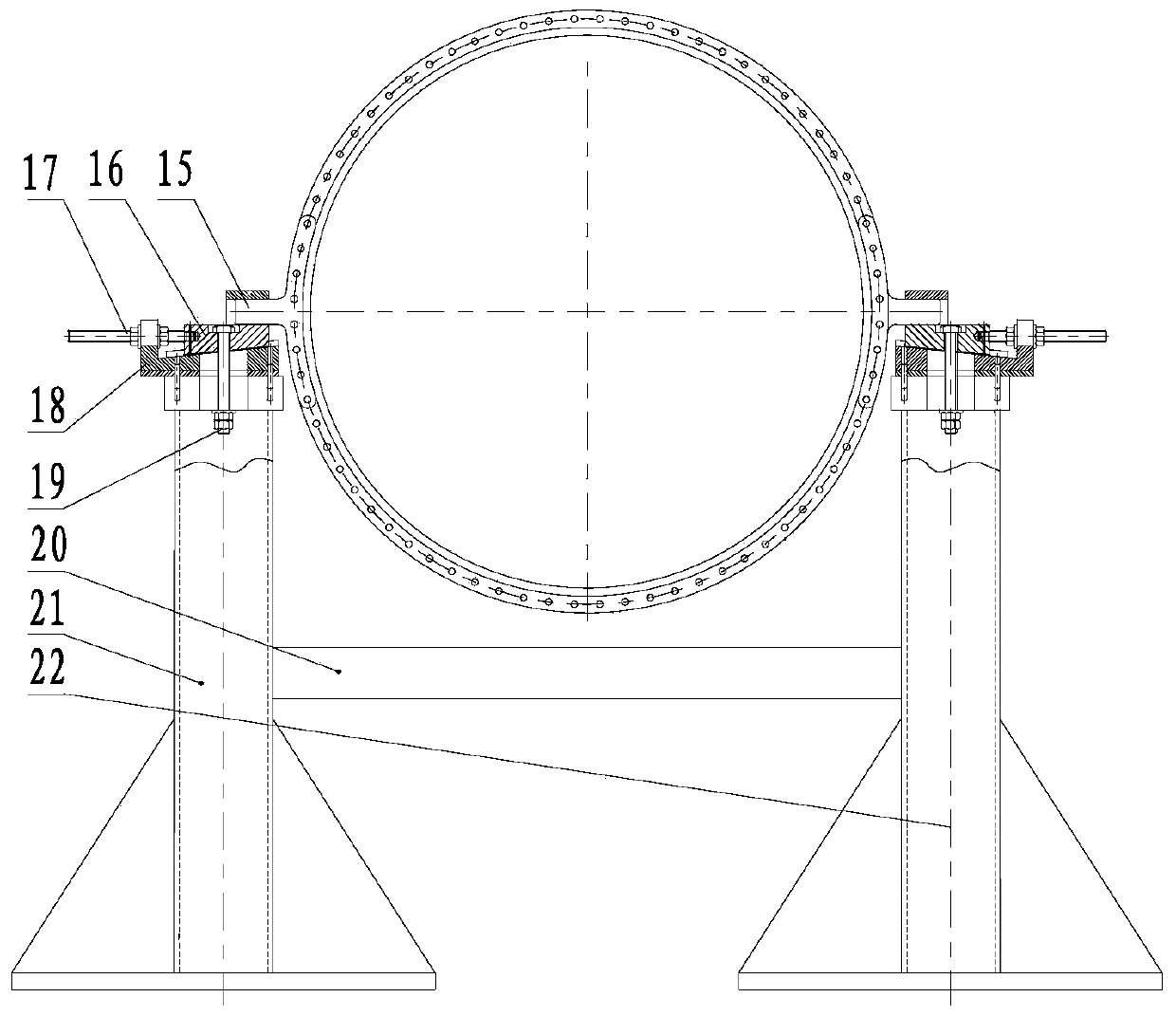

[0027] The complete installation method of the aviation axial flow compressor test piece on the special test equipment bench is mainly composed of three parts, namely: the connection method between the outlet of the compressor test piece and the exhaust duct of the test equipment; the outer case of the compressor test piece Auxiliary support method; the connection method between the inlet of the compressor test piece and the inlet pressure stabilizing box (23) of the test equipment. Among them, when installing and connecting the outlet of the compressor test piece and the exhaust duct of the test equipment, the working gap between the drive shaft of the compressor test piece and the output shaft of the test equipment is measured by the method of pre-installing the lead wire. By adding auxiliary supports on the inlet casing of the test piece, the rigidity of the casing is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com