Power system structure

A power system and power module technology, applied in the mechanical field, can solve the problems of small space and large volume of high-power converters, and achieve the effect of high-power structure, high power density and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, further describe the technical solution of the present invention, but the present invention is not limited to these embodiments.

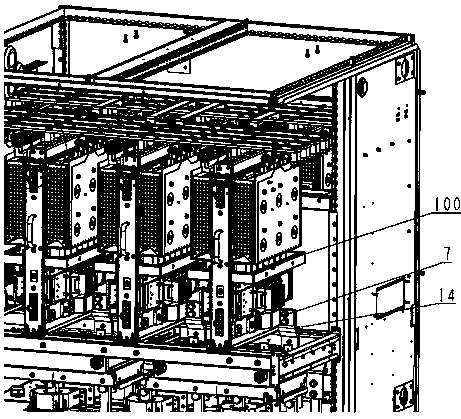

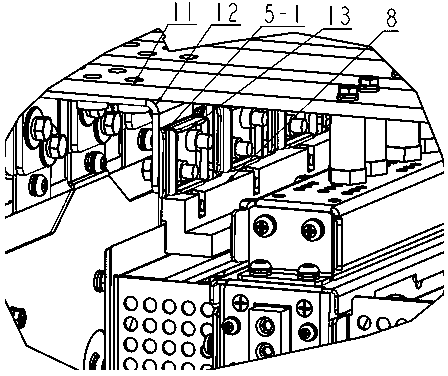

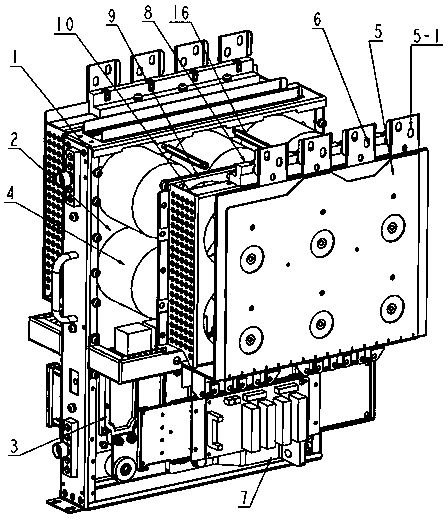

[0019] Such as figure 1 and figure 2 , a power system structure, including a power module and a structure connected to the system, wherein the power module 100 includes a module fixing bracket 1, a water cooling plate 2, an IGBT 3, a bus capacitor 4, a DC positive busbar 5, and a DC negative busbar row 6, AC copper bar 7, fixed block 8 of DC busbar, busbar capacitor fixing plate 9, busbar capacitor clamping plate 10 and capacitor clamping rod 16, such as image 3 The structure for system connection with the power module 100 includes the main bus bar copper bar 11, the transfer copper bar 12, the transfer copper bar nut plate 13, and the system AC copper bar 14; the DC positive bus bar 5 above the power module 100, the DC The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com