A double-sided electric fusion pipe fitting for composite pipe and its connection method

A technology of electrofusion pipe fittings and connection method, which is applied in the direction of pipe connection arrangement, pipe/pipe joint/pipe fitting, mechanical equipment, etc., can solve the problems of affecting installation cooperation, affecting sealing performance, difficult to achieve size, etc., and achieves simple installation and connection. , The effect of reliable installation connection and reliable installation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

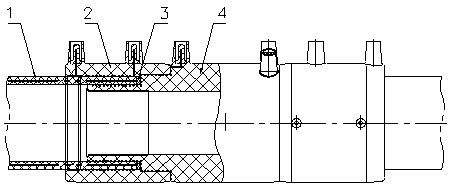

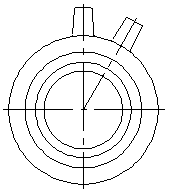

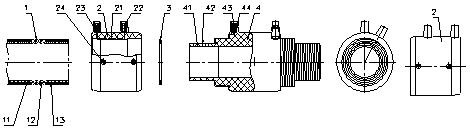

[0016] Embodiment 1: with reference to attached Figure 1-7 . A double-sided electric fusion pipe fitting for composite pipes. The pipe fittings are combined with split electric fusion pipe fittings. The heating wire 21 is arranged, and the two ends of the heating wire 21 are connected with the plug-in connector 22, and the joint protection sleeve 23 is arranged outside the connector, and the inner hole of the electrofusion pipe fitting 4 outside the sleeve is preset with a bushing 41 and the bushing 41 is a stainless steel sleeve or copper sleeve. A fusion measuring core 24 is injected at both ends of the electrofusion pipe fitting 2 in the sleeve. A joint protection sleeve 44 is provided outside the joint in the electrofusion fitting 4 outside the casing. Heating wires 42 are arranged on the outer cylindrical surface and the step end surface of the electrofusion fitting 4 outside the casing, and the two ends of the heating wires 42 are connected with plug-in connectors 43...

Embodiment 2

[0018] Embodiment 2: On the basis of Embodiment 1, when the interlayer of the composite pipe is metal, the gasket 3 is placed on the end face of the metal-plastic composite pipe.

Embodiment 3

[0019] Example 3: On the basis of Example 1, a method for connecting double-sided electrofusion pipe fittings for composite pipes. When the interlayer of the composite pipe is non-metallic, the electrofusion pipe fitting 2 in the sleeve is first placed outside the end of the composite pipe 1 surface, and then fit the 4-step end face of the electrofusion pipe fitting outside the casing with the 2-step end face of the electrofusion pipe fitting 2 inside the sleeve, fix the composite pipe and the pipe network, connect the electrofusion machine, and first connect the electrofusion pipe fitting 2 inside the sleeve with the composite pipe The outer surface 11 is melted into one body, and the outer convex state and size of the fusion measuring core are detected by the fusion measuring core 24, and whether the requirements are met; then the outer electrofusion pipe fitting 4 is connected to the inner surface 13 of the composite pipe and the inner electrofusion pipe fitting 2 of the slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com