Component-based single supporting frame

A supporting frame and component-based technology, which is applied in the direction of house structure support, house structure support, construction, etc., can solve the problems of complex leveling process of support plane, high labor intensity of workers, high labor intensity, etc., and achieve simple structure, low cost, and safety sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

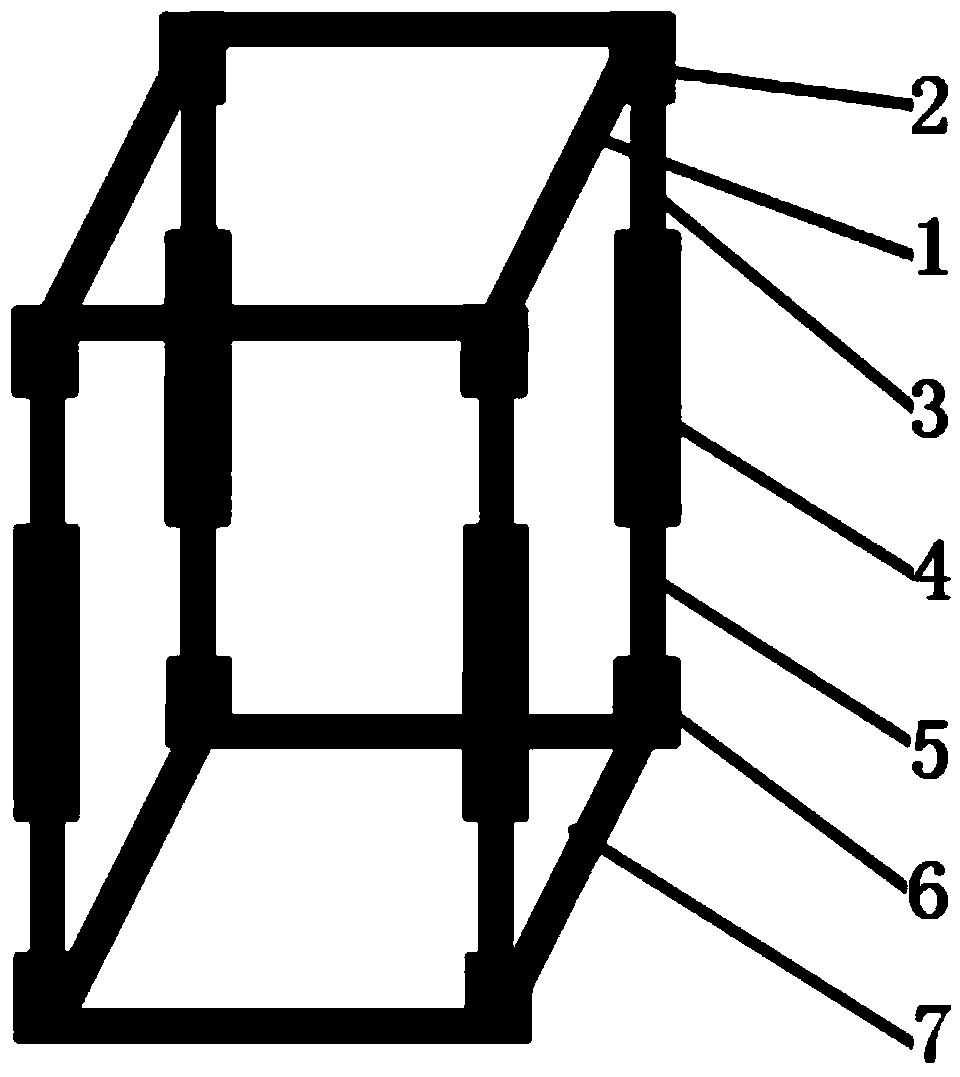

[0011] This embodiment (such as figure 1 Shown) the main structure includes an upper fixed frame 1, an upper sleeved round pipe 2, an upper support rod 3, an adjustment rod 4, a lower support rod 5, a lower sleeved round pipe 6 and a lower fixed frame 7; the upper fixed frame of the rectangular structure The frame 1 is welded by four cylindrical steel pipes, and the four corners of the upper fixed frame 1 are welded with upper sleeved round tubes 2, which are used for the wireless sleeve connection between the upper fixed frame 1 and the upper support rod 3, and the upper The length of the socketed round pipe 2 is three times its diameter; the upper end of the upper support rod 3 has no threads, and the lower end has threads, and the upper end of the upper support rod 3 has no wires sleeved on the upper sleeved round pipe 2, and the lower end has a thread sleeve Connected to the adjustment rod 4; the upper and lower ends of the adjustment rod 4 are threaded structures, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com