Construction method for shear wall concrete formworks and pillar concrete formworks

A technology of concrete formwork and construction method, applied in formwork/formwork/work frame, processing of building materials, preparation of building components on site, etc., can solve problems such as low construction efficiency, improve construction efficiency and wide adjustment range , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] The construction method of the shear wall concrete formwork provided by the present embodiment comprises the following steps:

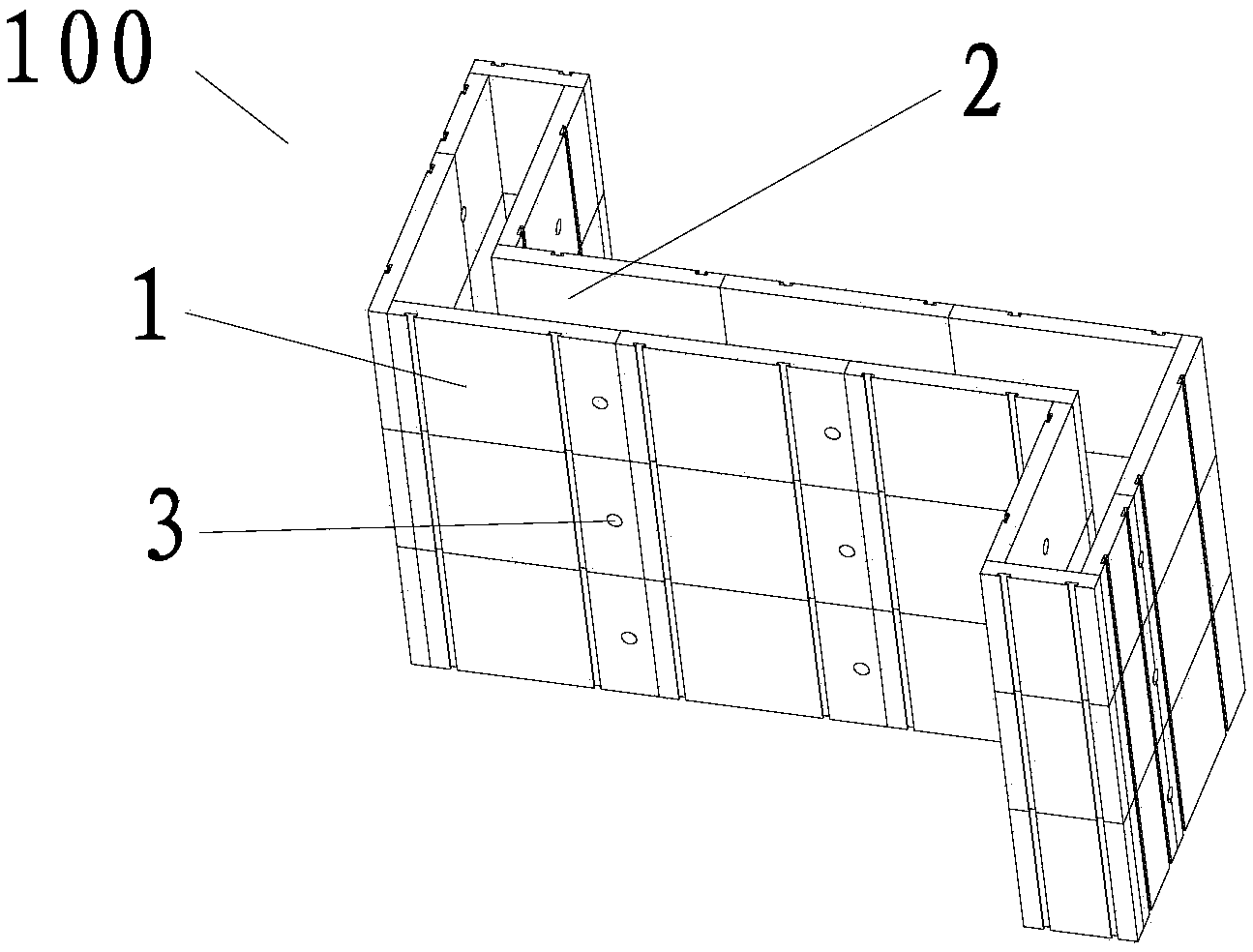

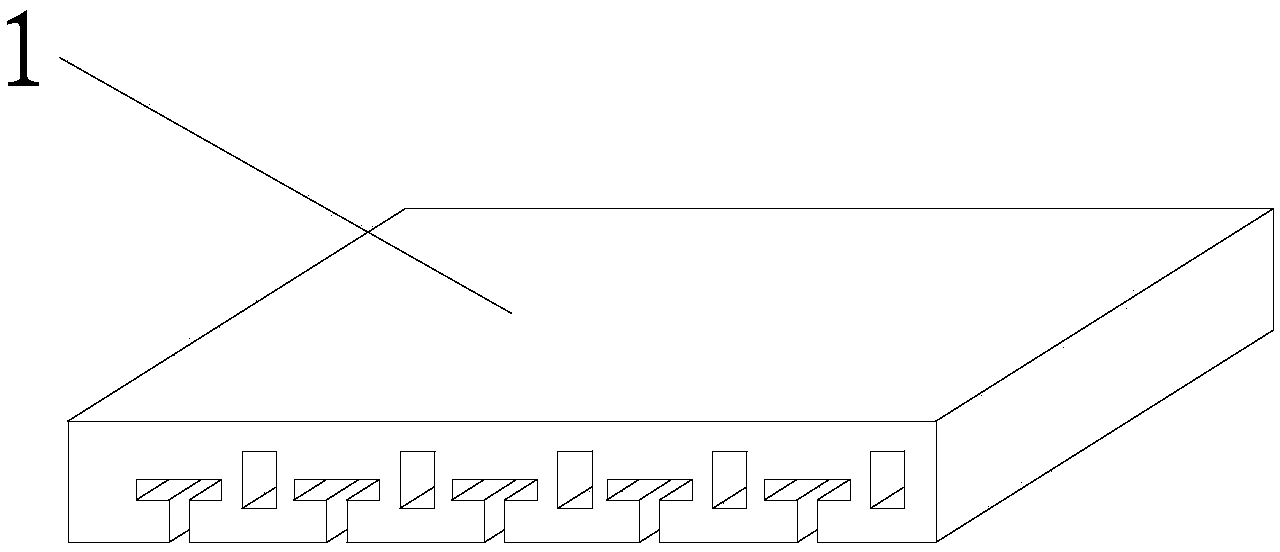

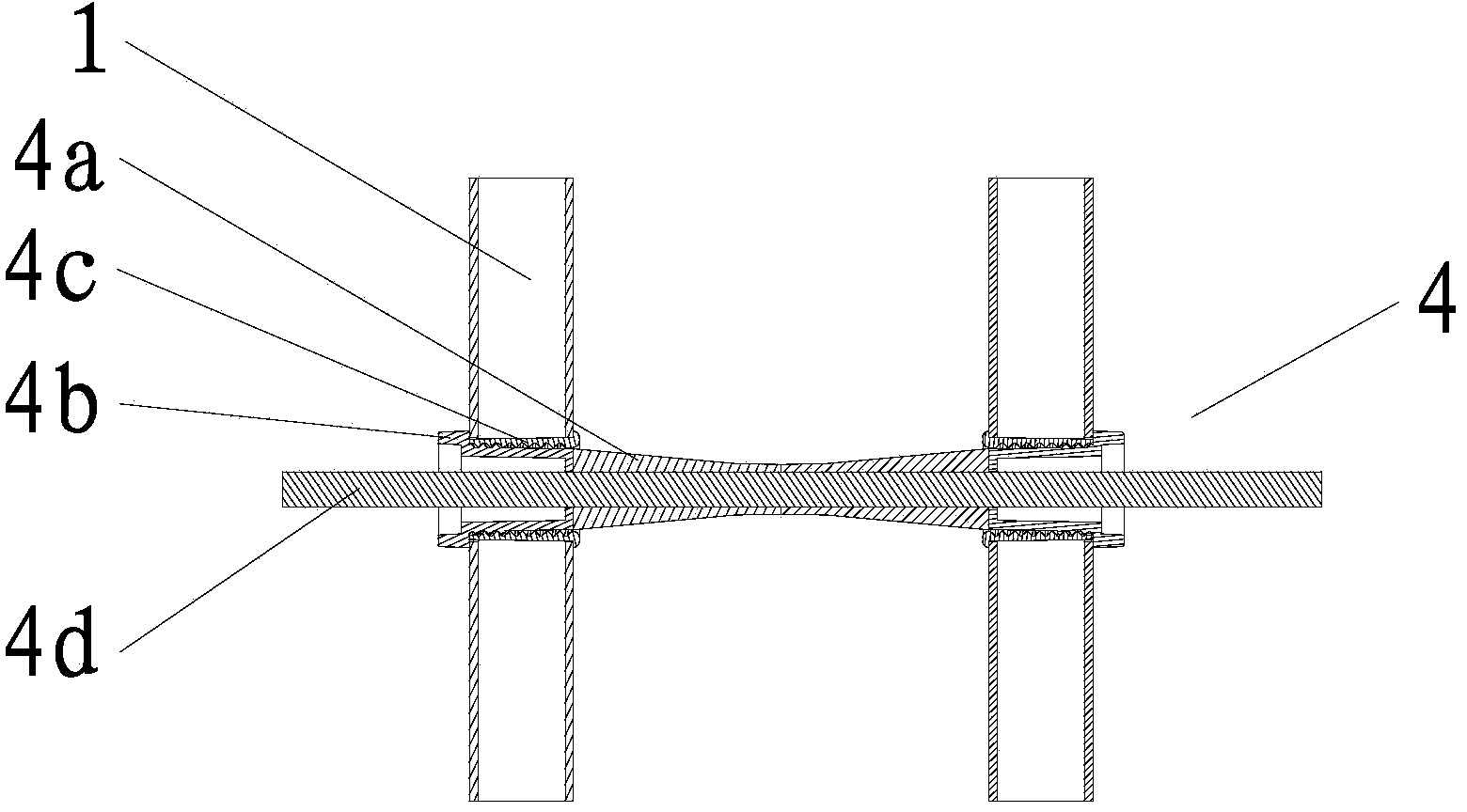

[0073] S1: Stitching templates, such as figure 1 As shown, the standardized concrete formwork 1 is spliced into a pre-designed shear wall formwork 100. The concrete formwork 1 can be a concrete formwork in the prior art, but it needs to be ensured that one side is a smooth surface, which is compatible with the concrete when pouring concrete grout. The slurry contacts and forms the surface of the condensed building component, and the other surface needs to be provided with quick-connect grooves or similar structures so that various fixtures can be installed. The concrete formwork 1 used in this embodiment is a Chinese utility model patent ZL201220200056. 8 disclosed concrete formwork, its structure is as figure 2 As shown, the size can be set according to actual needs. The shear wall formwork 100 is closed, and its closed interior forms a c...

Embodiment 2

[0089] The difference between this embodiment and Embodiment 1 is that in step S3, the gap in the horizontal direction between the concrete forms 1 on the same plane is also adjusted, and the adjustment method includes the following steps:

[0090] a. In step S3, after installing the horizontal fixed pipe 5, ensure that the horizontal fixed pipe 5 can move along its length direction under a predetermined force. The specific installation method is to lock the horizontal fixed pipe 5 on the concrete with the screw 6 On the formwork 1, properly control the locking force of the screw 6 so that it will not lock the horizontal fixing pipe 6 and the concrete formwork 1 too tightly. Move, the installation hole that is used for locking screw 6 on the horizontal fixed pipe 5 needs to be slightly larger than the outer diameter of screw 6, preferably be designed as the waist-shaped hole that the longitudinal direction is consistent with the horizontal fixed pipe 5 lengthwise. In addition,...

Embodiment 3

[0097] The difference between this embodiment and Embodiment 1 is that the concrete formwork 1 used in this embodiment is further improved on the basis of the concrete formwork disclosed in Chinese utility model patent ZL201220200056.8, which is disclosed in Chinese utility model patent ZL201220200056. In 8, the splicing surface of the concrete formwork 1 and its smooth surface are perpendicular to each other, that is, there is an angle of 90° between them. It is not convenient to disassemble after pouring concrete, and a large disassembly force is required. In this embodiment, the angle between the joint surface of the concrete formwork 1 and its smooth surface is changed from 90° to 45°. Those skilled in the art can also according to the size of actual dismantling force, only the fixture design of the part splicing surface of concrete formwork 1 and its smooth surface is 45 °, and other splicing surfaces are still 90 ° of included angles.

[0098] When using the concrete for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com