High-pressure fuel supply pump and diesel engine having such high-pressure fuel supply pump

An oil supply pump and high pressure technology, applied in the direction of mechanical equipment, fuel injection pumps, engine components, etc., can solve the problem that the size of the oil inlet spool cannot be further increased, and can reduce the error chain, improve oil absorption efficiency, and improve efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

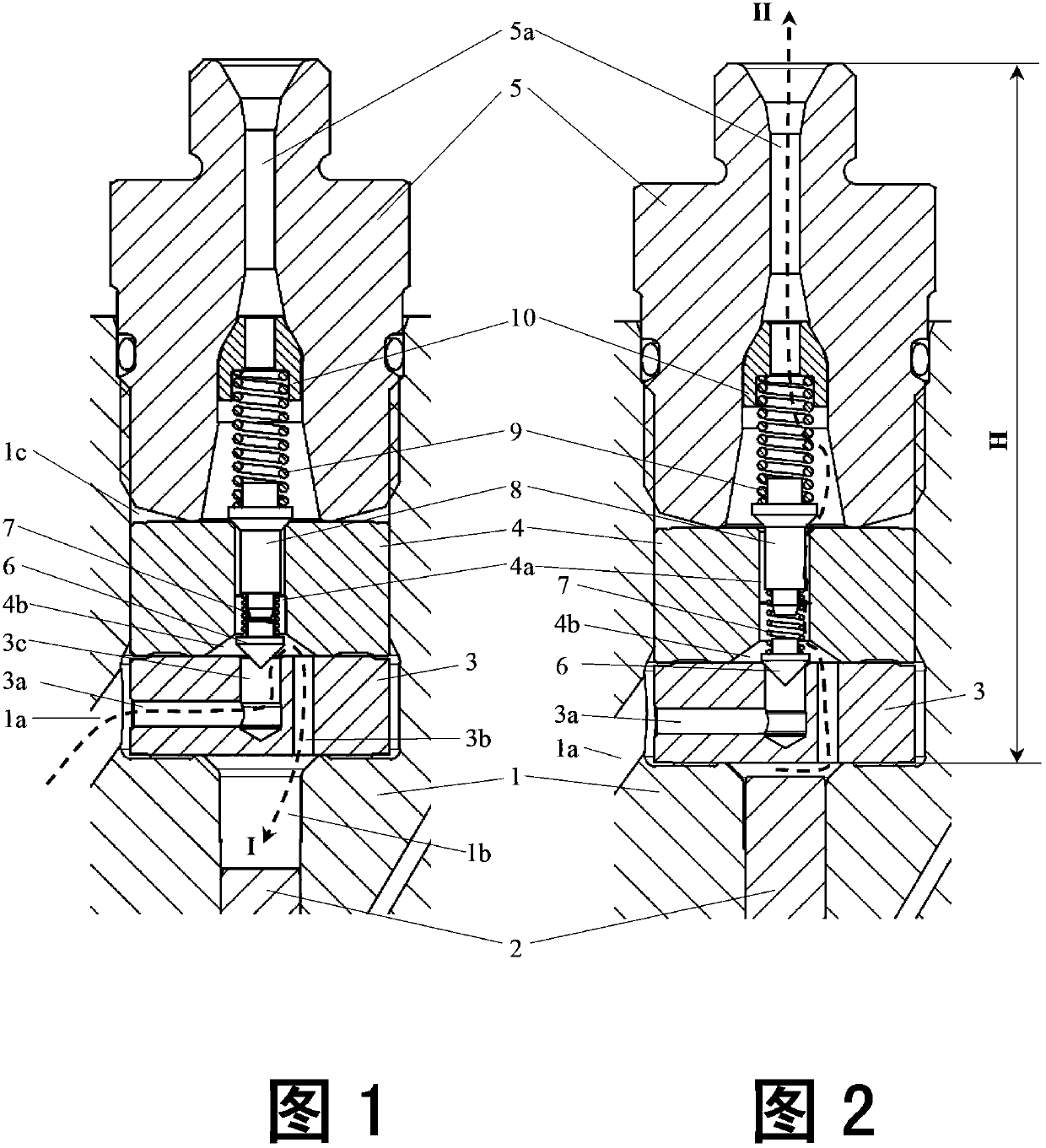

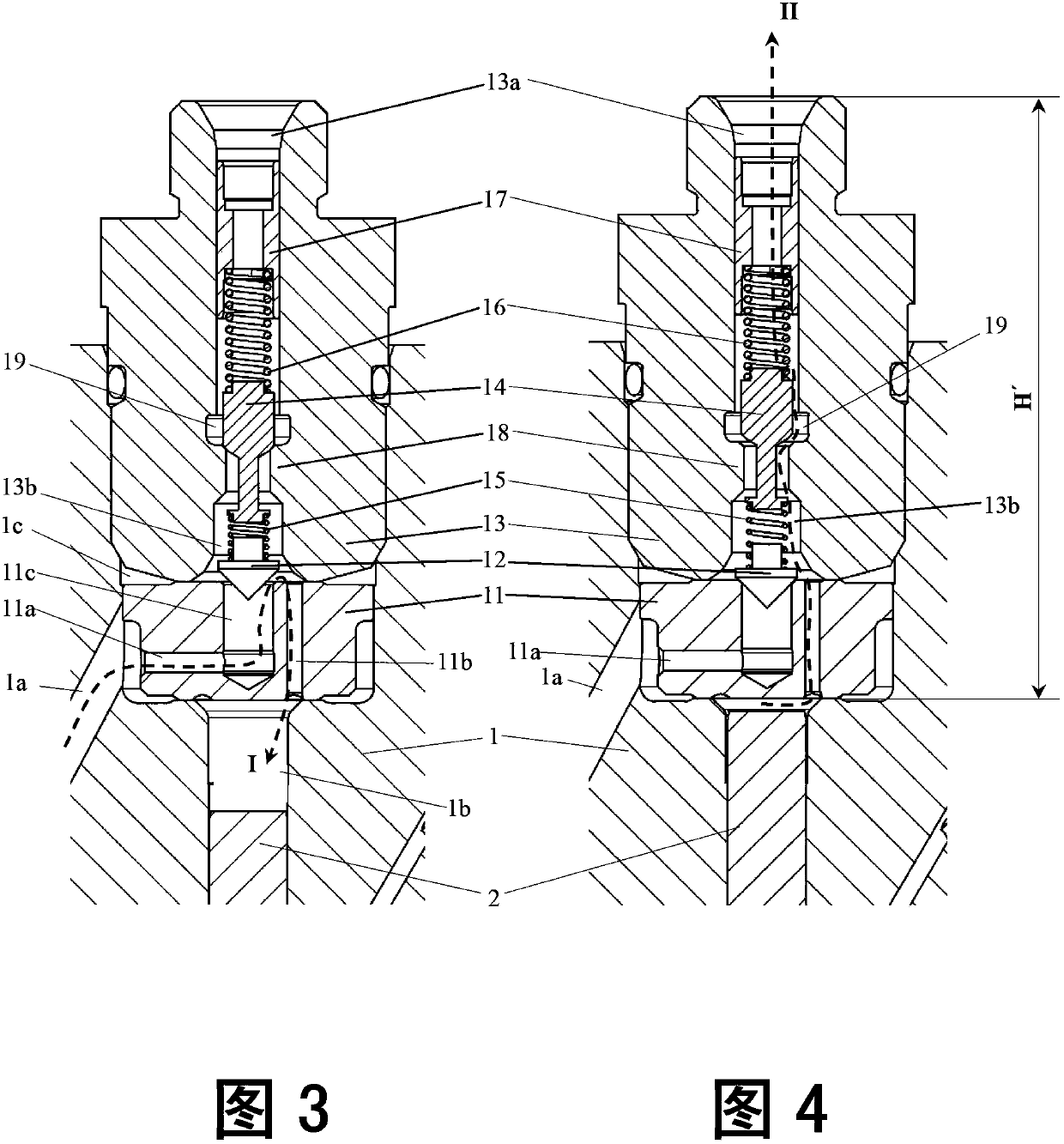

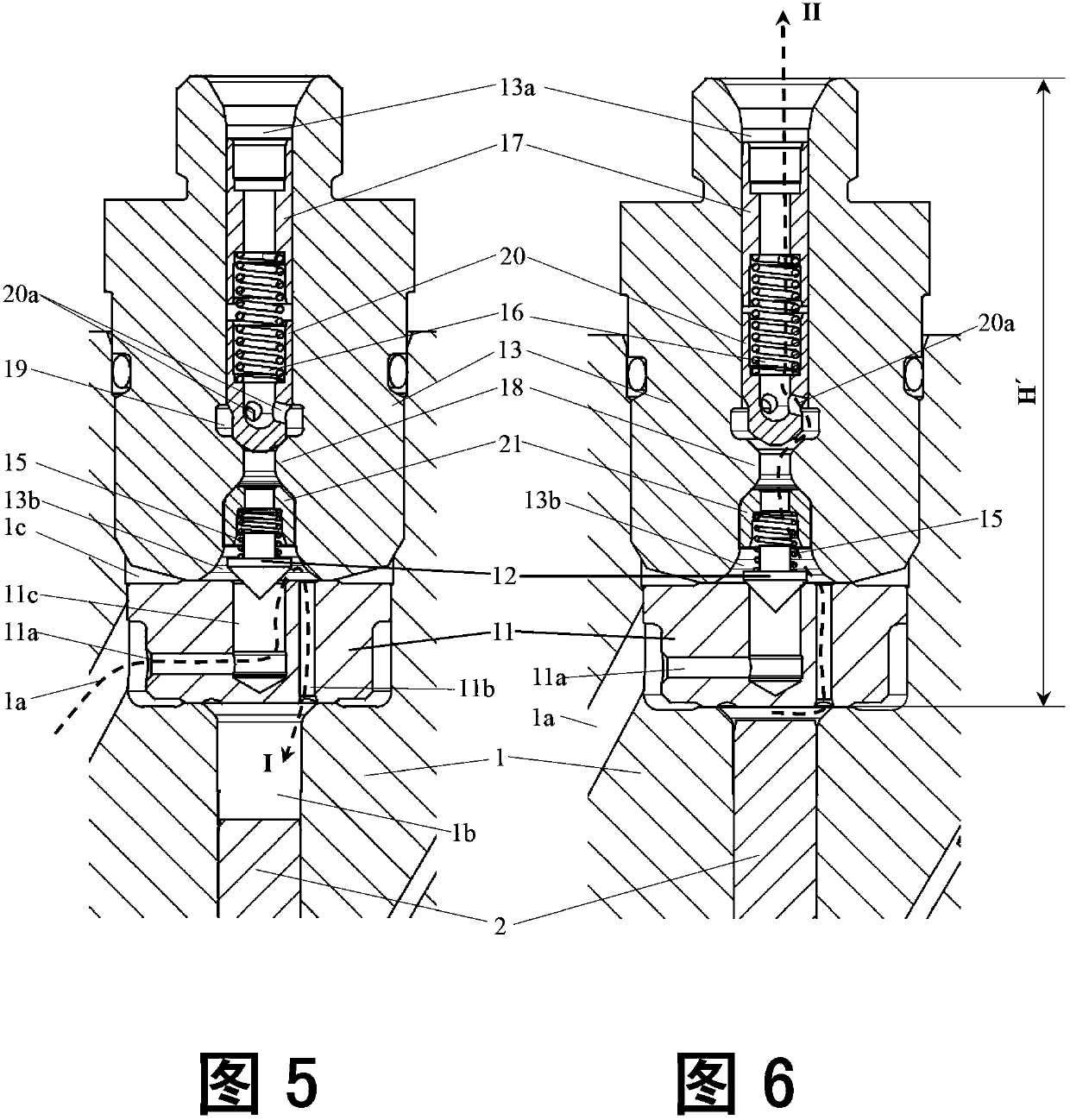

[0036] Illustrative embodiments of the present invention are described below with reference to the accompanying drawings. It should be noted that the same reference numerals in the drawings represent elements or components with the same function and / or structure. In addition, it should be pointed out that the cross-sectional views in the accompanying drawings refer to the cross-sectional views cut along the central axis of the high-pressure fuel supply pump.

[0037] In order to understand the technical solution more clearly, taking the plunger oil pump as an example, first refer to figure 1 and 2 Briefly introduce the high-pressure oil supply pump and its working principle in the prior art, among which figure 1 shows a prior art high pressure fuel supply pump in an oil suction state, and figure 2 A prior art high pressure fuel supply pump is shown in a state of oil pressure.

[0038] like figure 1 and 2 As shown, this high-pressure oil supply pump mainly includes a plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com