Traction molecular pump embedded inside the device

A technology of embedded devices and molecular pumps, applied in the field of molecular pumps, to achieve the effect of reducing screws and other parts, reducing processing difficulty, and ensuring the flow area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

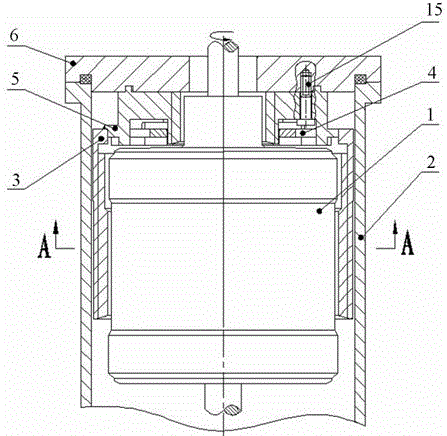

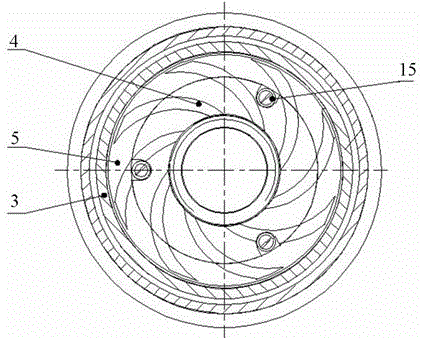

[0030] The traction molecular pump embedded in the device of the present invention will be described in detail below in conjunction with the embodiments and accompanying drawings:

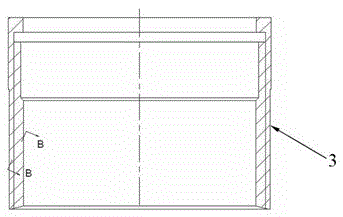

[0031] Such as Figure 1~8 As shown, a traction molecular pump embedded in the device includes a housing 2 with a cylindrical rotor 1 installed inside, and a hollow cylindrical first-stage molecular pump 3 coaxial with the rotor 1. The first-stage molecular pump The pump 3 is located between the side elevation of the rotor 1 and the inner wall of the casing 2, and the inner wall of the first-stage molecular pump 3 forms a spiral air pumping groove 7; The annular flange 8 forms a plurality of air extraction grooves 9 on the lower end surface. In this embodiment, the number of air extraction grooves 9 is 8, and a central through hole 10 is formed in the middle. The inner wall of the central through hole 10 forms a spiral air extraction groove 7. The lower part of the three-stage molecular pump 5 for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com