Modular soft package battery pack and electric equipment

A modular technology for electrical equipment, applied in the field of modular soft-pack battery packs and electrical equipment, can solve the problems of inconvenient fixed connection of soft-pack battery packs, large space occupied by connecting frames, inconvenient installation and layout, etc., to achieve Easy splicing and fixing with the battery box, easy splicing, easy installation and arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

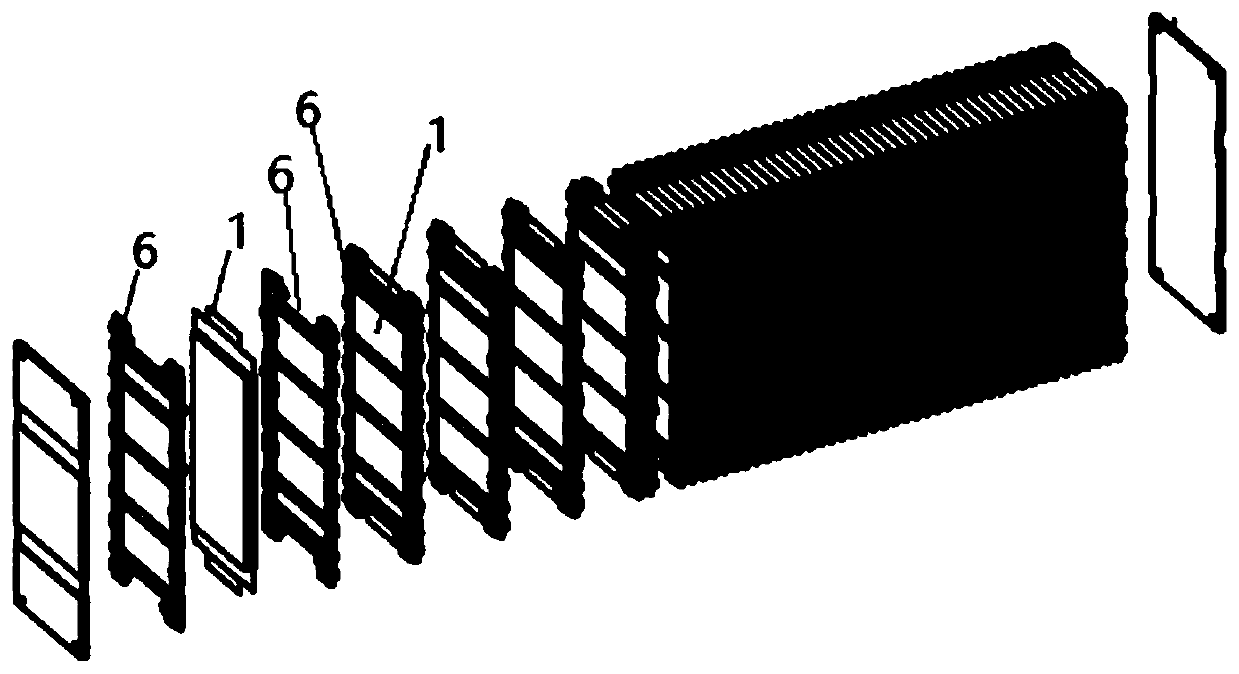

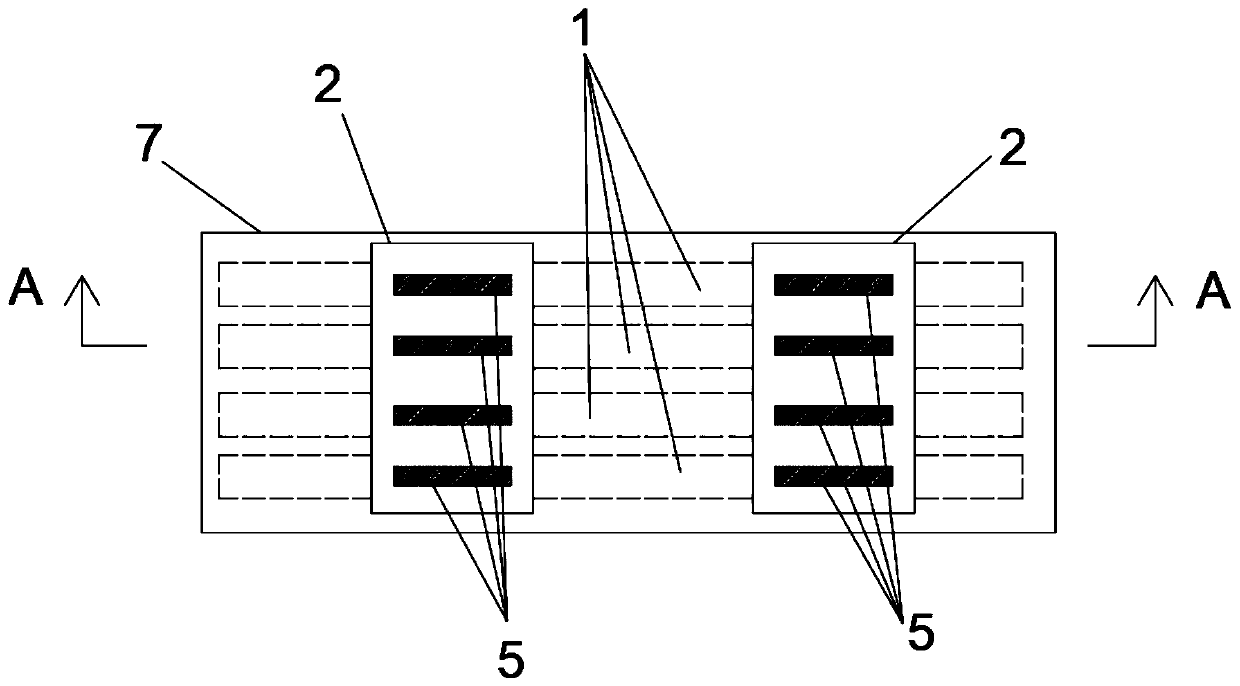

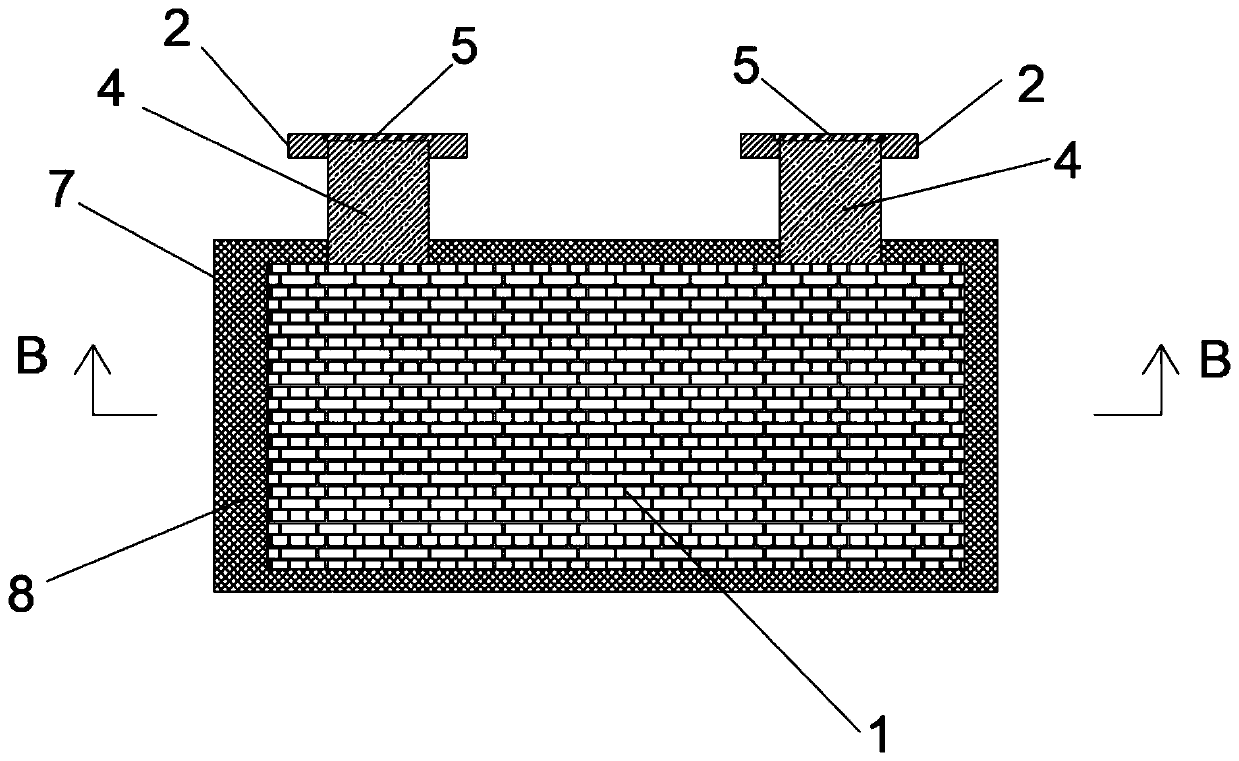

[0032] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0033] Such as Figure 1-Figure 6 As shown, the embodiment of the modular pouch battery pack disclosed in the present invention includes a battery cell 1 and a module case 7. There are multiple battery cells 1, and all the battery cells 1 are electrically connected through corresponding tabs 4, different The battery cells 1 can be connected in series or in parallel, all the battery cells 1 are fixed in the module shell 7, the module shell 7 is a cube, the battery cells 1 in the module shell 7 are arranged parallel to each other and parallel to the side of the module shell 7, The module case 7 is a weldable material, and multiple modular pouch battery packs can be directly welded and fixed through the module case 7 .

[0034] As a further solution of the above emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com