Hydraulic one-way valve

A one-way valve and hydraulic technology, applied in the field of hydraulic one-way valve, can solve the problems of valve core moving vibration, unable to reset seal, and noise generation, and achieve the effects of ensuring stability, fast flow speed, and reducing vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

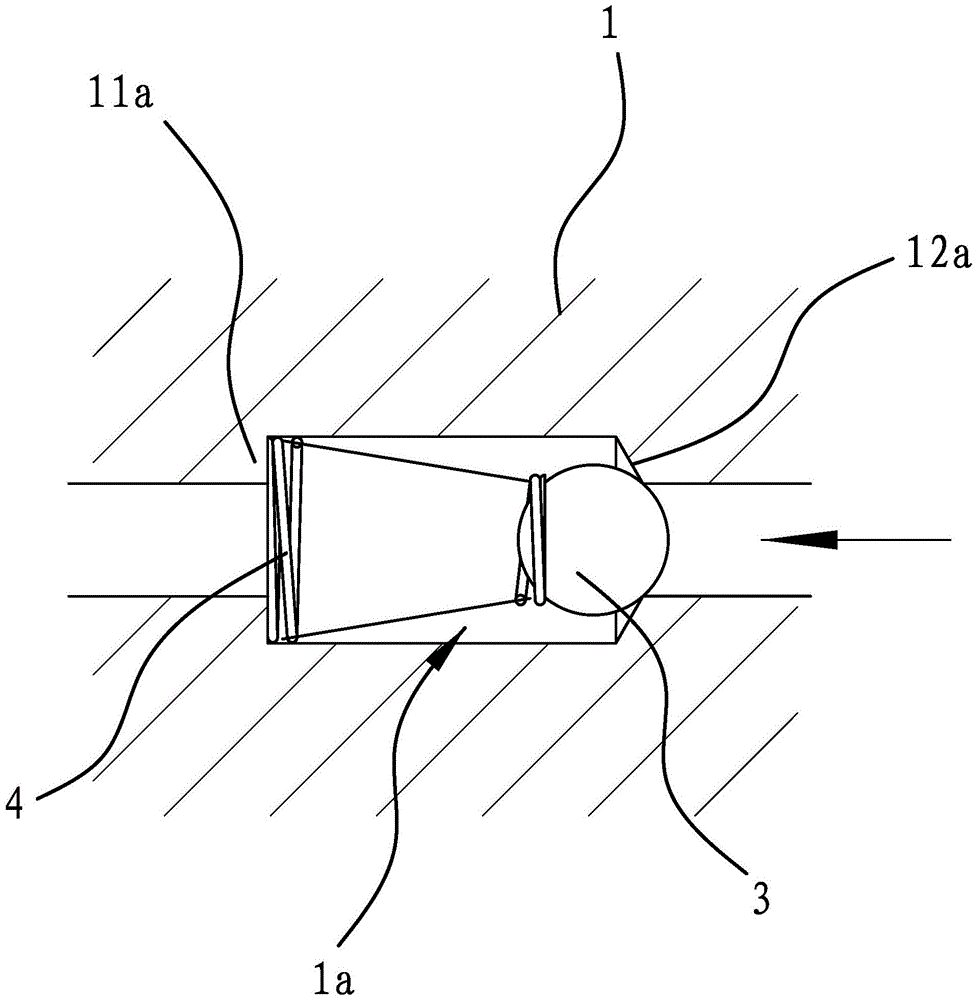

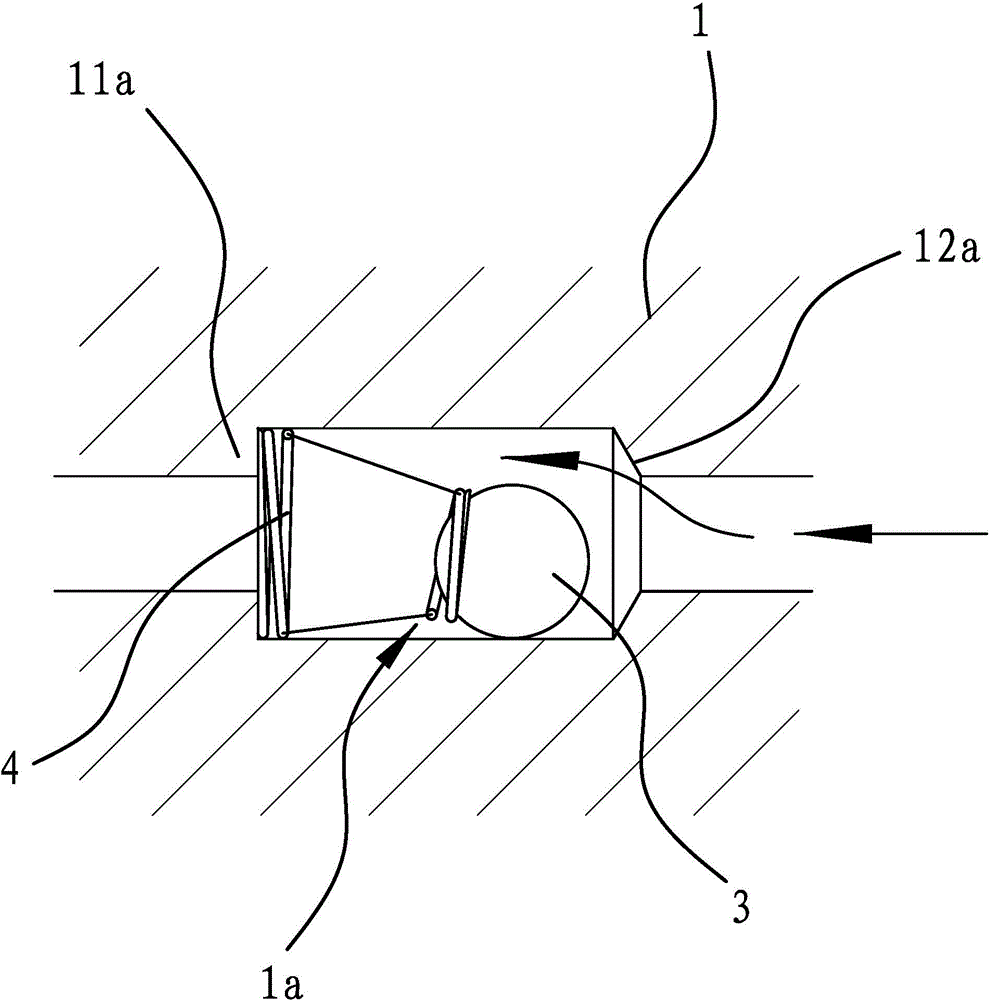

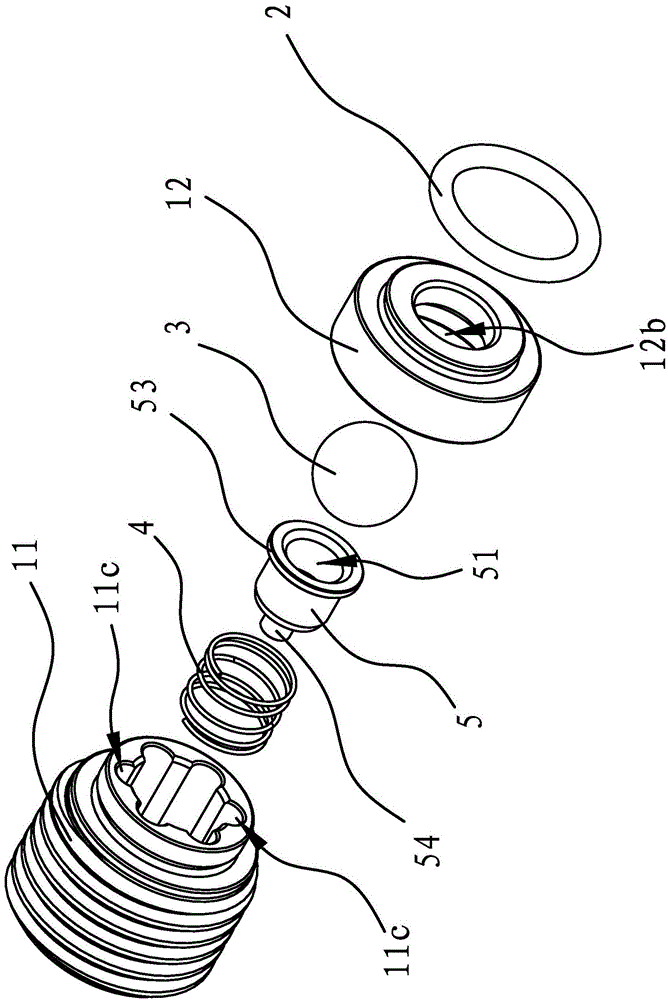

[0029] like image 3 and Figure 4 As shown, the hydraulic check valve is used at the oil outlet of the plunger pump, and includes a cylindrical body 1 with a through-hole 1a penetrating in the axial direction, a valve core 3 and a ball all arranged in the through-hole 1a. Holder 5 and spring 4, the inner wall of the front end of body 1 has an annular sealing surface 12a coaxial with body 1, and the inner wall of main body 1 rear end has an annular shoulder 11a coaxial with body 1. The spool 3 is located between the shoulder 11a and the sealing surface 12a, the spring 4 is arranged between the shoulder 11a and the spool 3 and the spool 3 can abut against the sealing surface 12a and form a seal under the elastic force of the spring 4, The ball holder 5 is arranged between the valve core 3 and the spring 4 .

[0030] In this embodiment, the valve core 3 is a bearing steel ball; the front part of the ball holder 5 has an opening 51 where the rear end of the valve core 3 can be ...

Embodiment 2

[0037] The technical solution in this embodiment is substantially the same as that in Embodiment 1, except that the hydraulic check valve in this embodiment is used at the oil inlet of the plunger pump, and both the valve body 11 and the valve seat 12 are cylindrical , the rear end of the valve seat 12 is sleeved on the outside of the valve body 11 and the two are threaded, the rear end surface of the valve seat 12 is flat with the rear end surface of the valve body 11; the strip hole 6 is opened on the front end surface of the valve seat 12 , the annular groove is located on the rear end surface of the valve seat 12;

[0038] In the hydraulic check valve, the radial limit of the spool 3 and the flow passage for the liquid medium to flow through can be used in addition to the above-mentioned technical solutions of the through hole 11b as a round hole and the flow groove 11c, the following technologies can also be used Solution: such as Figure 8 and Figure 9 As shown, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com