Device and method for automatic zero correction of automobile instrument pointer based on image processing and meta-programming technology

An automobile instrument and image processing technology, which is applied in the field of automatic zero correction device of automobile instrument pointer, can solve the problems of manual work, inaccurate zero position, and low precision, and achieve the effects of good scalability, improved accuracy, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

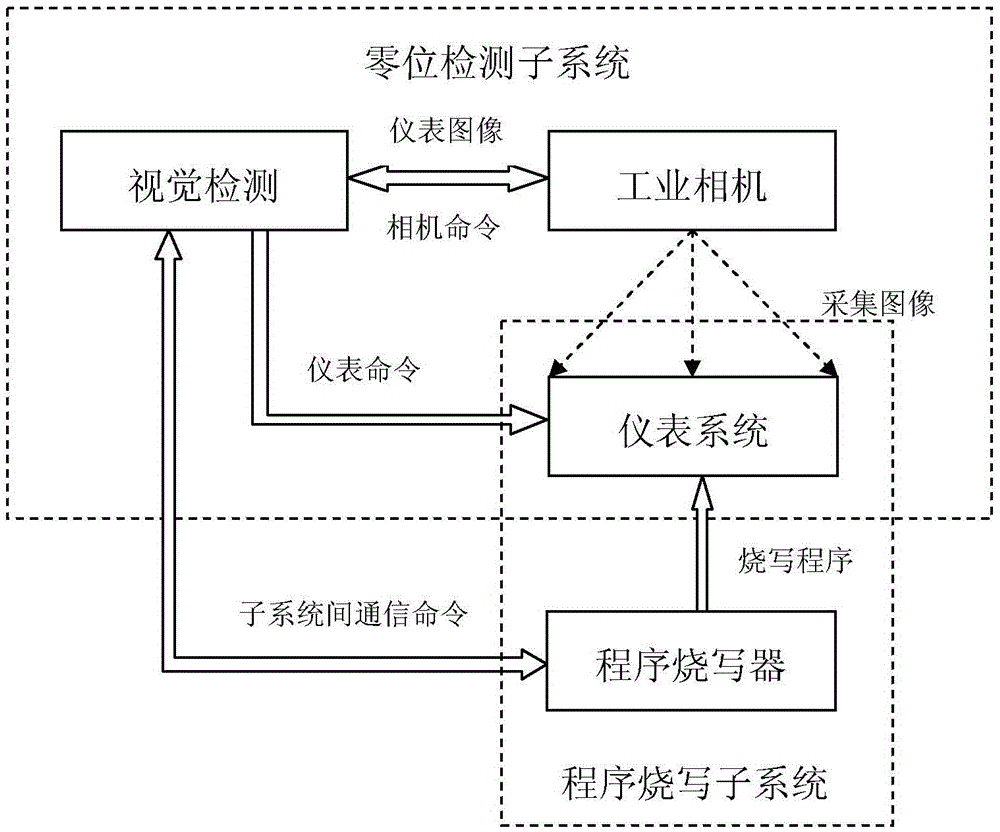

[0034] Specific implementation mode one: the following combination figure 1 and figure 2 Illustrate this embodiment, the auto meter pointer zero position automatic correction device based on image processing and meta-programming technology described in this embodiment, it comprises:

[0035] It is used to control the initialization of the automotive instrument system, control the industrial camera for image acquisition, process the grayscale image of the instrument collected by the industrial camera to obtain the zero deviation value of the instrument pointer; define the interface for obtaining the zero deviation value of the motor module, in the form of macro definition Declare the parameters to be adjusted by the motor module, write the zero deviation value and the parameters to be adjusted into the independent header file of the motor module, preset the default value of the motor module, and save the zero deviation value obtained from time to time as a macro The definitio...

specific Embodiment approach 2

[0043] Specific implementation mode two: the following combination figure 1 This embodiment will be described. This embodiment will further explain the first embodiment. In this embodiment, the grayscale image of the instrument collected by the industrial camera is processed to obtain the zero deviation value of the instrument pointer, which is realized by an image processing module, which includes:

[0044]The preprocessing module is used to perform image preprocessing on the grayscale image of the meter, and then perform binarization processing to obtain the grayscale image of the meter to be recognized;

[0045] An image processing module that is used to extract the dial scale information from the grayscale image of the instrument to be recognized to obtain the instrument panel image, then perform Hough circle transformation on the instrument panel image, and finally determine the center of the instrument panel circle;

[0046] A polar coordinate transformation module for p...

specific Embodiment approach 3

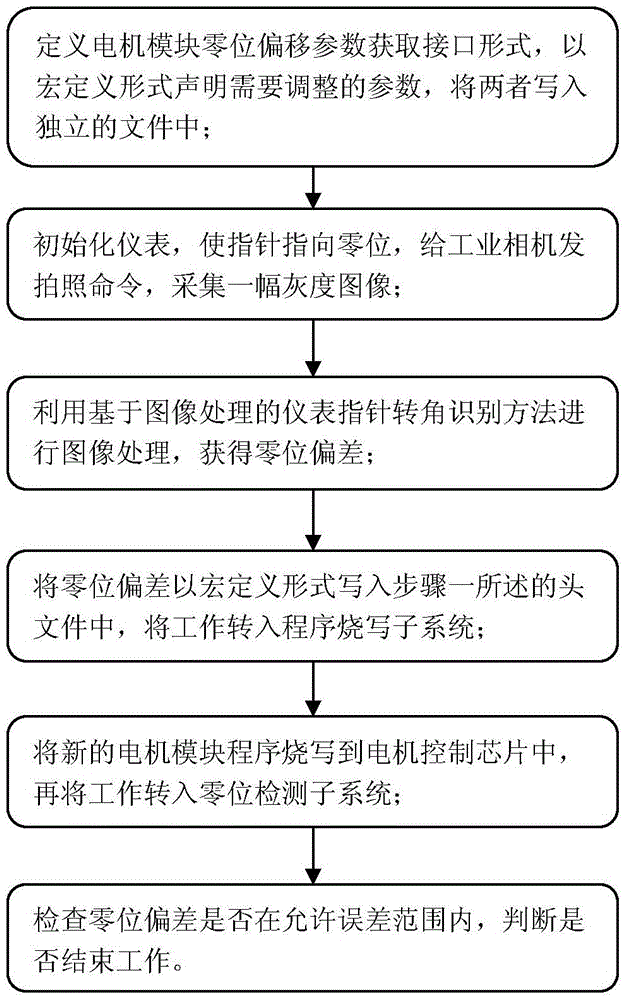

[0050] Specific implementation mode three: the following combination figure 1 and figure 2 Illustrate the present embodiment, the automobile meter pointer zero position automatic correction method based on image processing and meta-programming technology described in the present embodiment, it comprises:

[0051] It is used to control the initialization of the automobile instrument system through the visual detection module, control the industrial camera for image acquisition, process the grayscale image of the instrument collected by the industrial camera to obtain the zero deviation value of the instrument pointer; define the zero deviation value acquisition interface of the motor module, and Declare the parameters to be adjusted by the motor module in the form of macro definition, and write the zero deviation value and the parameters to be adjusted into the independent header file of the motor module, preset the default value of the motor module, and save the zero position...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap