Testing system for testing fatigue performance of helicopter main-rotor crossbeam

A test system and fatigue performance technology, which is applied in the field of test system for testing the fatigue performance of the helicopter main propeller girder, can solve the problems of complex loading, fatigue damage, lack of fatigue performance test system, etc., and achieve the effect of high measurement accuracy and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

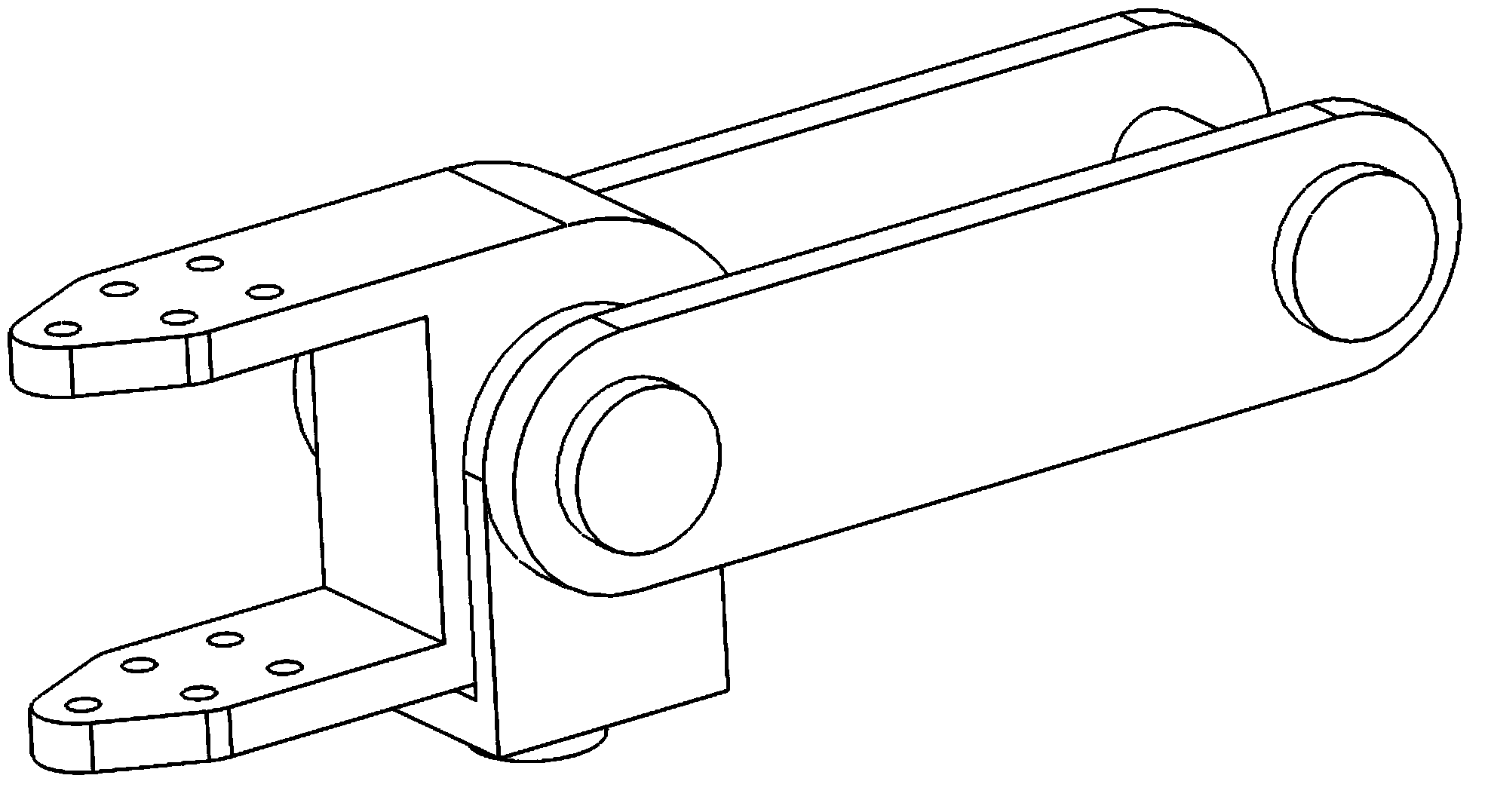

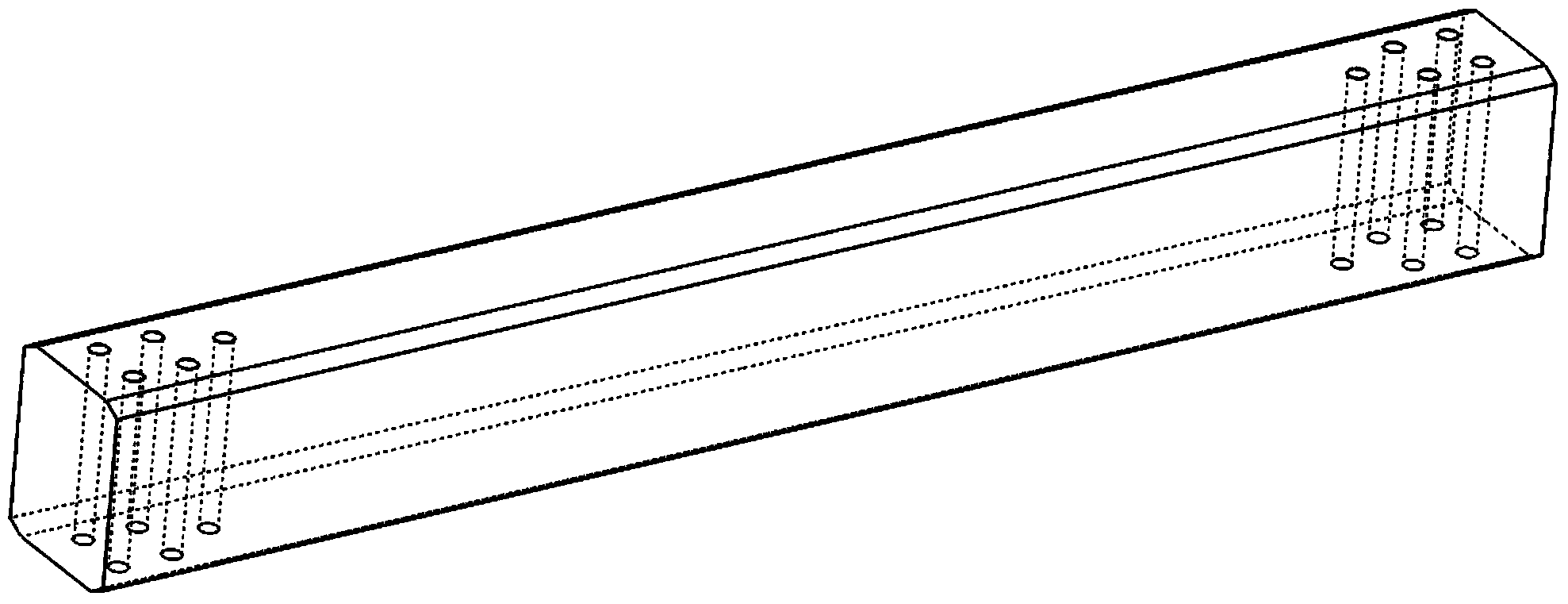

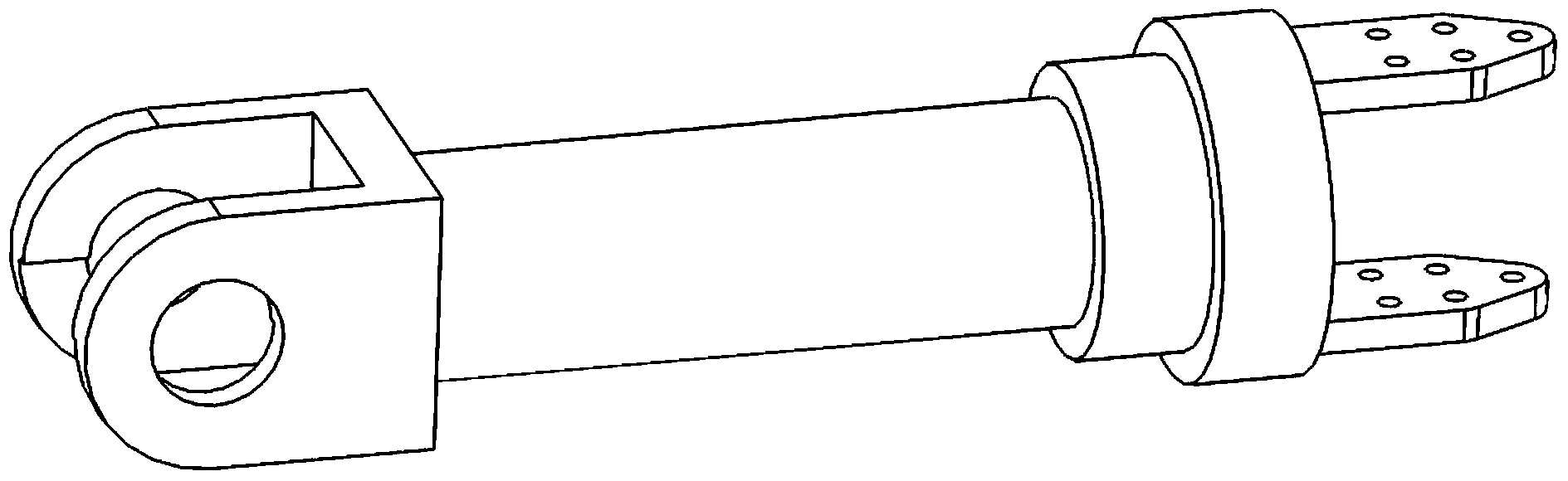

[0028] Specific implementation mode one: combine Figure 7 Specific embodiments of the present invention will be described. The present invention is a test system for testing the fatigue performance of the main propeller girder of a helicopter, which consists of a process joint 1, a strain gauge 2, a test piece 3 at the root of the main propeller girder of a helicopter, a loading joint 4, a hydraulic system 5, a test bench 6, a vibration exciter 7, Composed of motor 8, electric control cabinet, dynamic strain gauge, optical oscilloscope and hydraulic control cabinet. exist Figure 7 Among them, one end of the test piece 3 at the root of the main propeller girder of the helicopter is installed on the process joint 1; 7 is connected with the loading joint 4 and installed on the test bench 6; the motor 8 is connected with the exciter 7; the electric control cabinet is connected with the motor 8; the hydraulic system 5 is connected with the loading joint 4; the hydraulic control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com