A large mask template surface compensation device for lithography equipment

A technology of compensation device and lithography equipment, which is applied in the direction of microlithography exposure equipment, photolithography exposure device, etc., can solve the problems of self-weight deformation of large mask plates, etc., and achieve the goal of improving compensation efficiency, improving imaging quality, and good adsorption effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

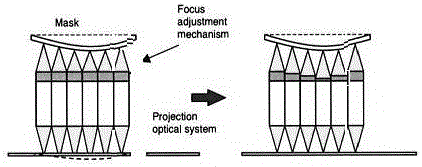

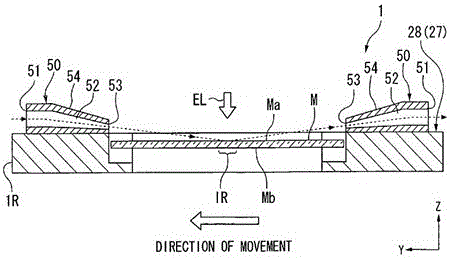

[0039] Figure 4 It is the first embodiment of the structure of the photolithography system and the compensation device for the large mask template of the present invention.

[0040] Figure 4 The surface compensation device of the illustrated embodiment is located between the lighting unit 1 of the lithography machine and the mask plate 2 , and includes: a glass plate 6 , a support frame for the glass plate, and an exhaust control unit 9 .

[0041] The transparent glass plate 6 is located above the mask plate 2 and arranged parallel to the mask plate 2 , and a number of extraction holes 8 are provided on the glass plate 6 . The glass plate 6 is fixedly arranged relative to the objective lens group 4 and at least covers the current exposure area of the mask plate 2 .

[0042] The exhaust control unit 9 is connected to the exhaust hole 8 through the exhaust pipeline 10, which exhausts the gap between the glass plate 6 and the mask plate 2 through the exhaust hole 8, and for...

no. 2 example

[0051] Figure 5a with Figure 5b It is the second embodiment of the large mask surface compensation device of the present invention.

[0052] Figure 5a with Figure 5b The surface compensation device of the illustrated embodiment is located between the lighting unit of the lithography machine and the mask plate 2, and includes: a glass plate 6, a glass plate support frame 7, and an exhaust control unit.

[0053] The transparent glass plate 6 is located above the mask plate and arranged parallel to the mask plate, and the glass plate 6 is provided with a number of extraction holes. The glass plate 6 is fixedly arranged relative to the objective lens group, and at least covers the current exposure area of the mask plate.

[0054] The exhaust control unit is connected to the exhaust hole through the exhaust pipeline, which exhausts the gap between the glass plate 6 and the mask plate through the exhaust hole, and forms a pressure difference between the upper and lower sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com