Steelmaking input-output monitoring system

A monitoring system and monitoring unit technology, applied in the direction of total factory control, total factory control, electrical program control, etc., can solve the problems of no unified network, unsmooth process control, and low efficiency of production cost management, so as to facilitate production The effect of the situation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical solution and advantages of the present invention clearer, the technical solution of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

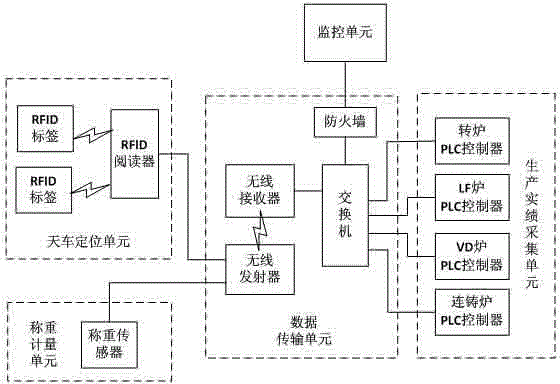

[0025] Such as figure 1 As shown, a steelmaking input-output monitoring system of the present invention includes a monitoring unit, a data transmission unit, a crane positioning unit, a weighing measurement unit and a production performance collection unit, a crane positioning unit, a weighing measurement unit and a production The actual performance acquisition unit is connected to the monitoring unit through the data transmission unit, wherein:

[0026] The monitoring unit adopts the PowerEdge C6220 server, obtains the furnace number of the ironmaking furnace where the crane is located through the MES system, and receives, stores and displays the data collected by the crane positioning unit, weighing and measuring u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com