Multifunctional back plate used for installing and cooling future fusion reactor breeding cladding

A breeder cladding, multi-functional technology, applied in fusion reactors, thermonuclear fusion reactors, nuclear reactors, etc., can solve the problems of increasing maintenance time and complexity, pipeline integration and fixing difficulties, etc., to improve maintenance efficiency and convenience. Centralized design, the effect of preventing tritium leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

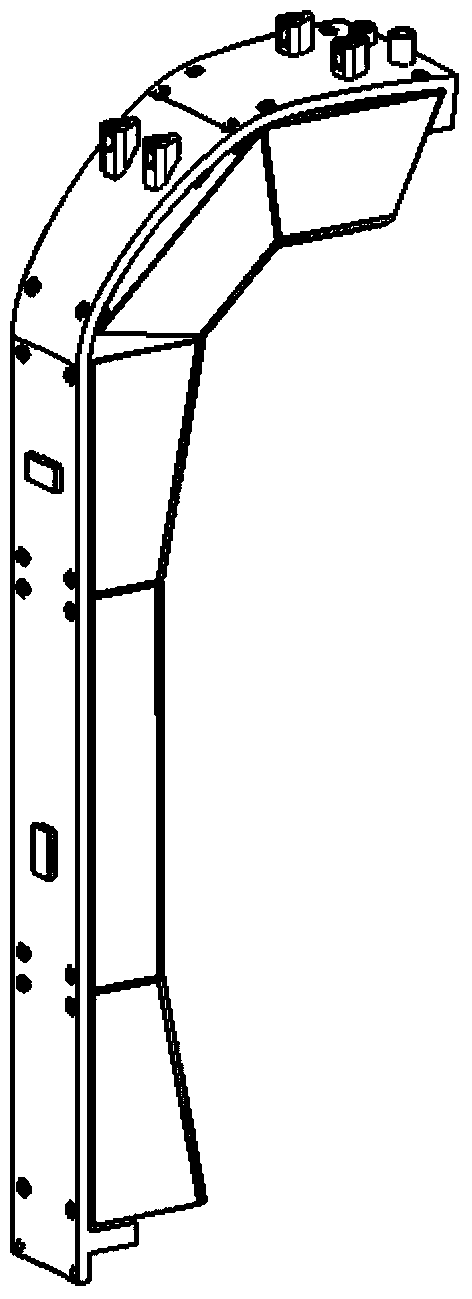

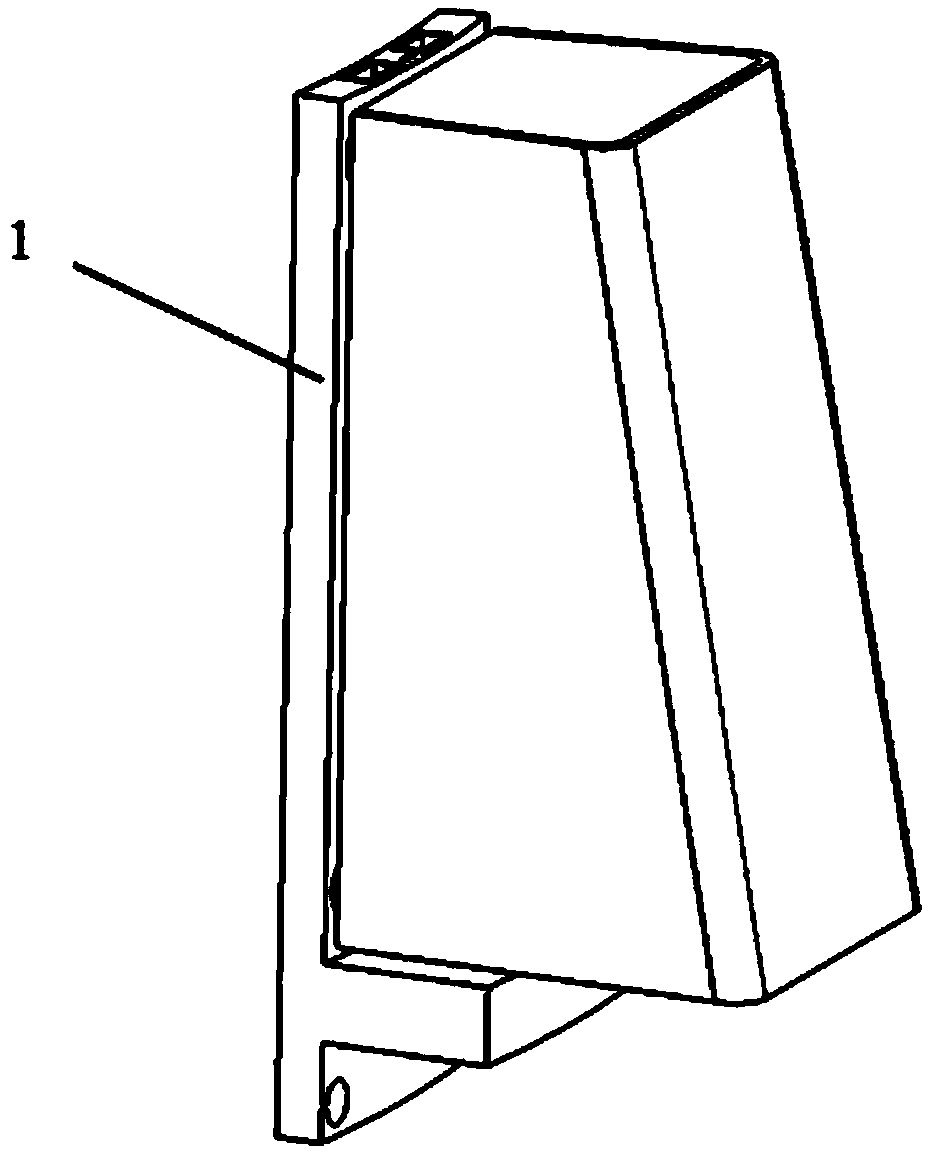

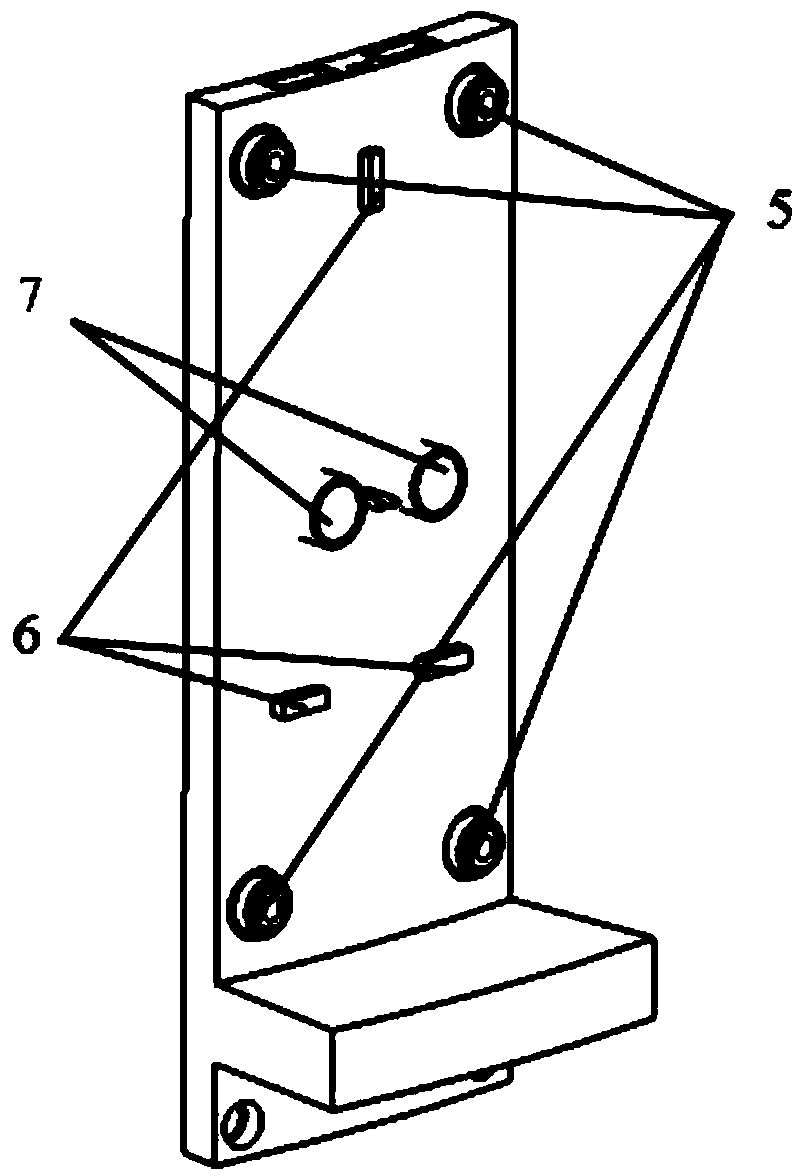

[0019] Such as figure 1 , 2 , a kind of multifunctional backboard that is used to install and cool future fusion reactor breeding cladding shown in 3, 4, comprises support backboard 1, is provided with backboard self-cooling circulation pipeline 2, breeding bag on the support backboard 1 Layer cooling pipeline 3, tritium extraction pipeline 4, etc. Four flexible supports 5 and three positioning keys 6 are designed between the support backplane 1 and each multiplication cladding block, and the multiplication cladding cooling pipeline 3 is designed with an inlet and outlet 7 for entering and exiting the cladding, and passes through a series of partitions 8 is connected to the backplane self-cooling circulation pipeline 2, the diameter of the inlet and outlet 7 is determined according to the coolant flow required by each cladding, and the contact surface of the backplane self-cooling circulation pipeline 2 and the multiplication cladding cooling pipeline 3 is coated with The he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com