Ball joint and manufacturing method therefor

一种球窝接头、制造方法的技术,应用在连接、枢轴连接、轴承等方向,能够解决无法球部流通焊接电流等问题,达到接触面压减弱、圆滑动作的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

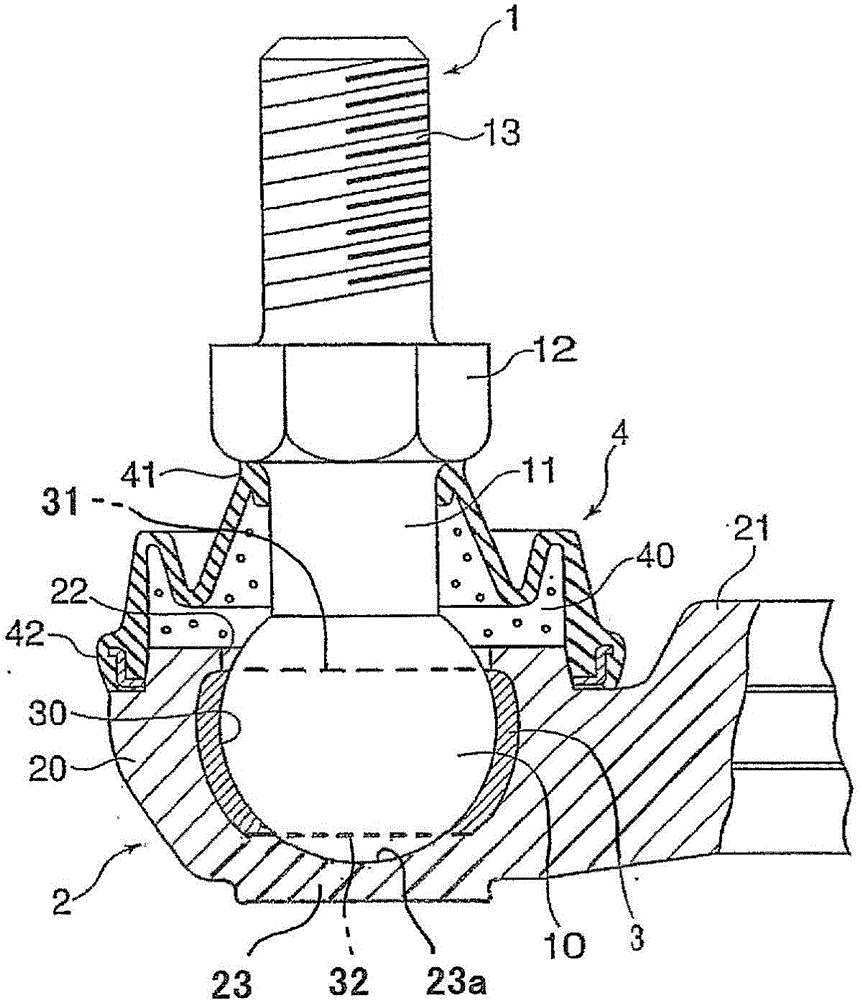

[0031] Hereinafter, the ball joint and its manufacturing method of the present invention will be described in detail using the drawings.

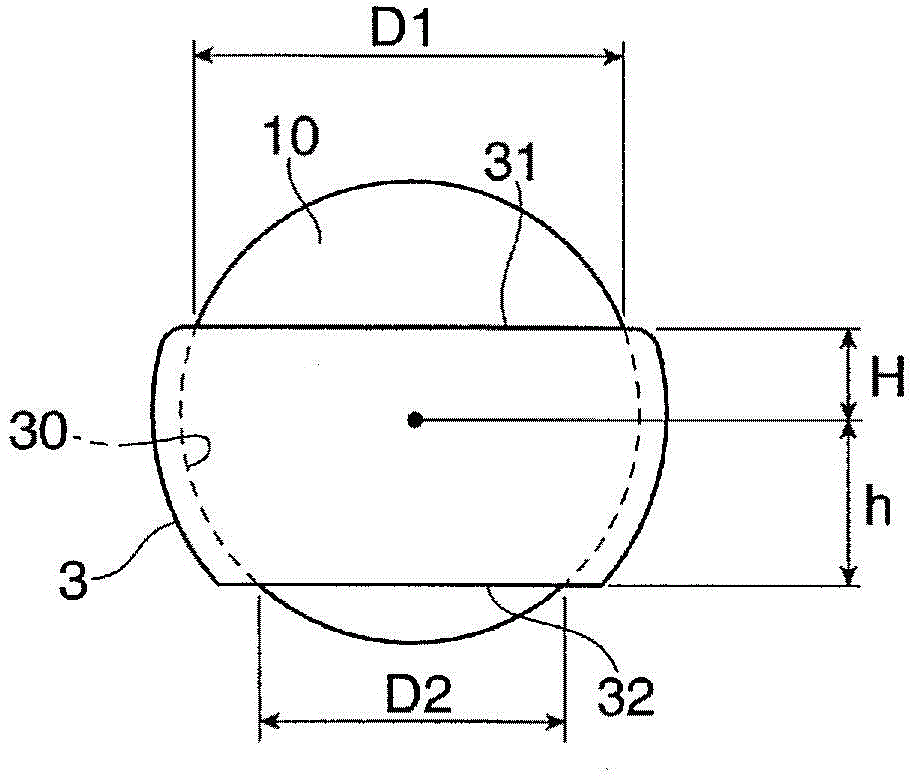

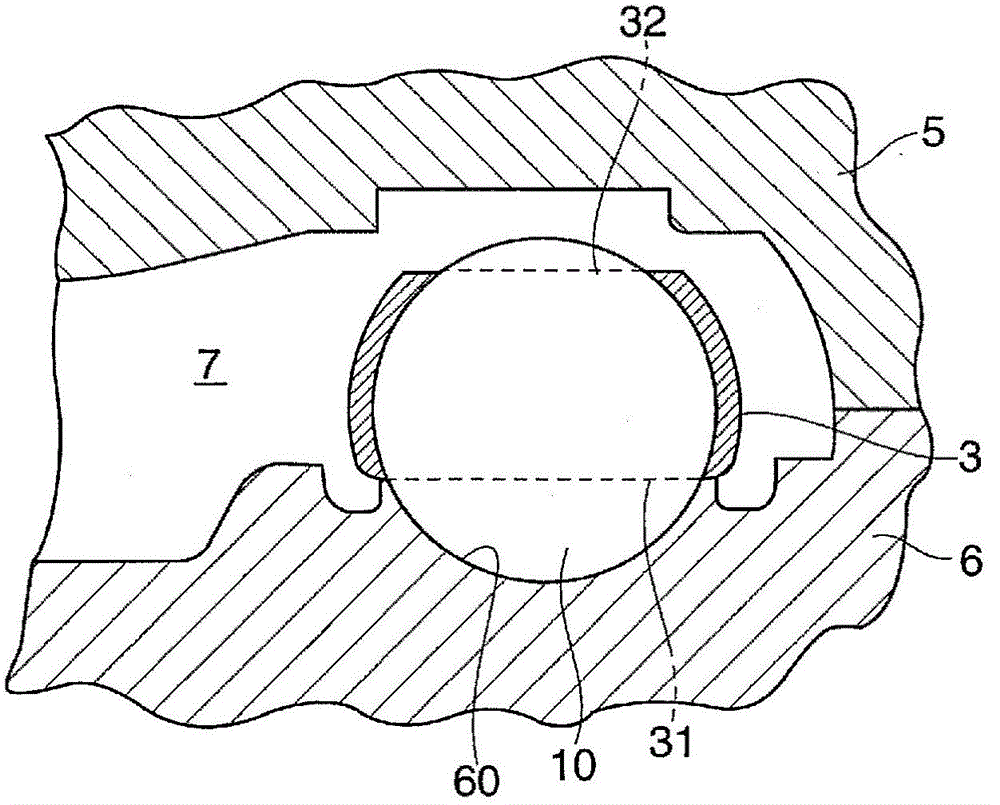

[0032] figure 1 It is a figure which shows the 1st embodiment of the ball joint manufactured by this invention. This ball joint is formed by a ball stud 1 having a ball portion 10 at the tip of a shaft member 11, a resin sliding contact member 3 that covers the ball portion 10 and is in sliding contact with the ball portion 10, and a resin sliding contact member 3 formed on the resin sliding contact member 3. The member 3 is surrounded by a retainer 2 that fixes the resin sliding contact member 3, and the ball stud 1 is connected so as to be swingable relative to the retainer 2 centering on the ball portion.

[0033]The ball stud 1 is formed by resistance welding a rod-shaped shaft member 11 to a high-sphericity bearing steel ball serving as the ball portion 10 . The shaft member 11 is formed with a flange portion 12 provided with a suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com