Adhesive for ceramic tile and preparation method of adhesive

A technology of tile adhesive and antifungal agent, applied in the field of building materials, can solve the problems of waste materials, tile oxidation, repeated working hours, etc., and achieve the effect of high whiteness and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

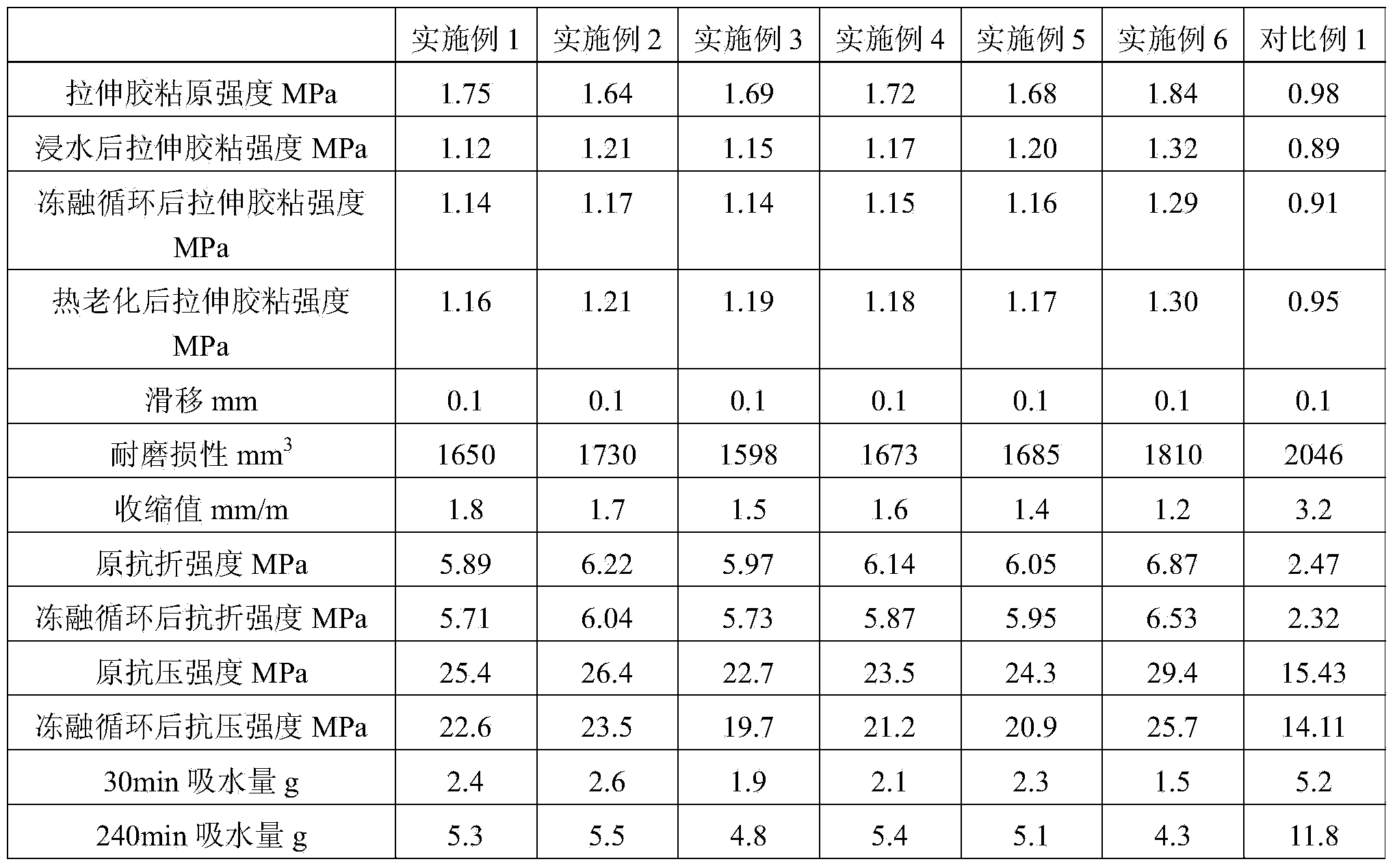

Examples

Embodiment 1

[0021] A tile adhesive, comprising in parts by weight: 40 parts of polyacrylate emulsion, 5 parts of phthalate, 2 parts of butyl rubber, 0.8 part of quartz powder, 1.2 parts of hydroxyethyl methyl cellulose ether, sodium base 4 parts of bentonite, 1 part of lignin fiber, 0.3 part of naphthenic petroleum, 2 parts of toluene, 0.2 part of calcium carbonate, 0.1 part of dibutyl phthalate, 3 parts of phthalimide, 1 part of diethanolamine, 0.5 part of diethylenetriamine, 1 part of polybutene, 0.4 part of calcium-titanium pigment, 0.1 part of cobalt desiccant, 0.1 part of benzimidazole antifungal agent.

[0022] The solid content of the polyacrylate emulsion is 40%.

[0023] First mix polyacrylate emulsion, phthalate, butyl rubber, lignin fiber, naphthenic petroleum and toluene, heat up to 80°C, stir evenly, and let it cool to obtain mixture I; add hydroxyl Ethyl methyl cellulose ether, dibutyl phthalate and phthalimide were kept at 60°C under 80MPa for 1h under stirring, and after ...

Embodiment 2

[0025] A tile adhesive, comprising in parts by weight: 50 parts of polyacrylate emulsion, 7 parts of phthalate ester, 3 parts of butyl rubber, 1.2 parts of quartz powder, 1.8 parts of hydroxypropyl methylcellulose ether, calcium base 6 parts of bentonite, 2 parts of lignin fiber, 0.7 part of naphthenic petroleum, 3 parts of toluene, 0.4 part of calcium carbonate, 0.2 part of dibutyl phthalate, 4 parts of phthalimide, 2 parts of diethanolamine, 0.8 part of diethylenetriamine, 2 parts of polybutene, 0.6 part of calcium-titanium pigment, 0.2 part of cobalt desiccant, 0.2 part of benzothiazole fungicide.

[0026] The solids content of the polyacrylate emulsion was 50%.

[0027] First mix polyacrylate emulsion, phthalate, butyl rubber, lignin fiber, naphthenic petroleum and toluene, heat up to 60°C, stir evenly, and let it cool to obtain mixture I; add hydroxyl Propyl methyl cellulose ether, dibutyl phthalate and phthalimide were kept under stirring at 40°C for 3 hours at 100 MPa,...

Embodiment 3

[0029] A tile adhesive, comprising in parts by weight: 60 parts of polyacrylate emulsion, 8 parts of phthalate ester, 4 parts of butyl rubber, 1.5 parts of quartz powder, 2 parts of hydroxyethyl methyl cellulose ether, calcium base 7 parts of bentonite, 4 parts of lignin fiber, 0.8 part of naphthenic petroleum, 4 parts of toluene, 0.5 part of calcium carbonate, 0.4 part of dibutyl phthalate, 5 parts of phthalimide, 3 parts of diethanolamine, 0.8 part of diethylenetriamine, 4 parts of polybutene, 0.7 part of calcium-titanium pigment, 0.2 part of cobalt desiccant, 0.4 part of benzimidazole antifungal agent.

[0030] The solids content of the polyacrylate emulsion was 55%.

[0031] First mix polyacrylate emulsion, phthalate, butyl rubber, lignin fiber, naphthenic petroleum and toluene, heat up to 70°C, stir evenly, and let it cool to obtain mixture I; add hydroxyl Ethyl methyl cellulose ether, dibutyl phthalate and phthalimide were kept under stirring at 50°C for 2 hours at 90 M...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap