A β-sialon/al 2 o 3 Composite powder and its preparation method

A technology of composite powder and silicon powder, which is applied in the field of β-Sialon/Al2O3 composite powder and its preparation, can solve the problems of high synthesis temperature and many impurities in the product, and achieves low synthesis temperature, high product purity and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A β-Sialon / Al 2 o 3 Composite powder and its preparation method. 40-45wt% of alumina powder, 35-40wt% of silicon powder and 15-20wt% of aluminum powder are used as raw materials, and 0.1-1.0wt% of iron is added to obtain the mixture.

[0028] The mixture is placed in a corundum ball mill jar, and then the mass ratio of corundum balls:mixture:ethanol is 2~3:1:0.5~1.5, and corundum balls and ethanol are added to the corundum ball mill jar, and ball milled for 2 ~4 hours. Then dry at 110°C for 16-36 hours, and then calcined at 1200-1300°C and nitrogen atmosphere for 4-6 hours to obtain β-Sialon / Al 2 o 3 Composite powder.

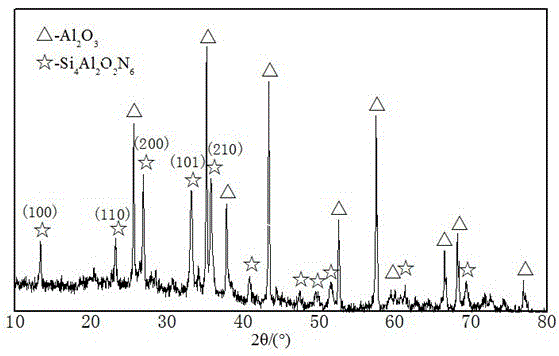

[0029] The β-Sialon / Al prepared in this embodiment 2 o 3 Composite powder, after testing: the total content of β-Sialon and alumina composite powder is 97~99wt%; among them, the content of β-Sialon powder is 53~57wt%.

Embodiment 2

[0031] A β-Sialon / Al 2 o 3 Composite powder and its preparation method. The mixture is obtained by using 40-45wt% alumina powder, 35-40wt% silicon powder and 15-20wt% aluminum powder as raw materials, plus 1.0-2.0wt% cobalt.

[0032] The mixture is placed in a corundum ball mill jar, and then the mass ratio of corundum balls:mixture:ethanol is 2~3:1:0.5~1.5, and corundum balls and ethanol are added to the corundum ball mill jar, and ball milled for 2 ~4 hours. Then dry at 110°C for 16-36 hours, and then calcined at 1150-1250°C and nitrogen atmosphere for 3-5 hours to obtain β-Sialon / Al 2 o 3 Composite powder.

[0033] The β-Sialon / Al prepared in this embodiment 2 o 3 Composite powder, after testing: the total content of β-Sialon and alumina composite powder is 98~99wt%; among them, the content of β-Sialon powder is 56~59wt%.

Embodiment 3

[0035] A β-Sialon / Al 2 o 3 Composite powder and its preparation method. The mixture is obtained by using 40-45wt% of alumina powder, 35-40wt% of silicon powder and 15-20wt% of aluminum powder as raw materials, plus 2.0-3.5wt% of nickel.

[0036]The mixture is placed in a corundum ball mill jar, and then the mass ratio of corundum balls:mixture:ethanol is 2~3:1:0.5~1.5, and corundum balls and ethanol are added to the corundum ball mill jar, and ball milled for 2 ~4 hours. Then dry at 110°C for 16-36 hours, and then calcined at 1100-1200°C and nitrogen atmosphere for 2-4 hours to obtain β-Sialon / Al 2 o 3 Composite powder.

[0037] The β-Sialon / Al prepared in this embodiment 2 o 3 Composite powder, after testing: the total content of β-Sialon and alumina composite powder is 98~99wt%; among them, the content of β-Sialon powder is 60~64wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com