Structural performance tester

A technology of structural performance and tester, which is applied in the field of tester, can solve problems such as personnel injury, overall product crushing, surrounding environmental pollution, etc., and achieve the effect of easy cleaning, simple structure and high safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

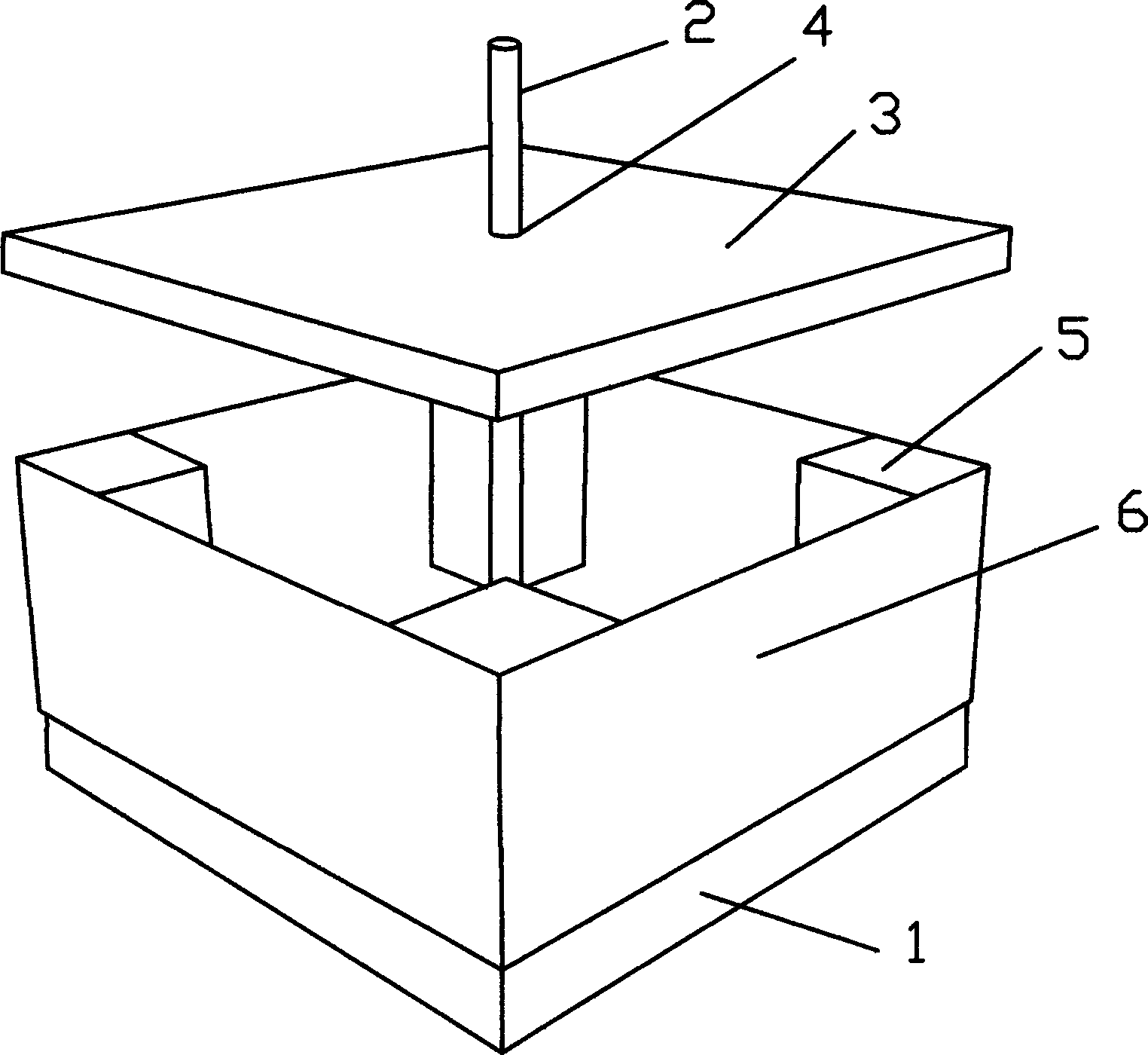

[0014] Such as figure 1 The shown structural performance tester is worth noting that it includes a tester base 1, and a safety cylinder 2 is affixed to the center of the tester base 1, and the safety cylinder 2 is vertically affixed to the base 1. A load-bearing plate 3 is slidably connected to the above-mentioned safety cylinder 2, and a through hole 4 is provided in the center of the load-bearing plate 3. The safety cylinder 2 passes through the through-hole 4 in the center of the load-bearing plate through the load-bearing plate 3, and on the base of the tester Safety supports 5 are installed on each corner of the upper surface of 1, and each safety support 5 is of the same height, and a safety shield 6 is provided outside between each safety support 5 . The safety shield 6 is made of transparent material. The base 1 is a cuboid structure, and the length and width of the base 1 are 45.7cm; the load-bearing plate 3 is a cuboid structure, and the length and width of the load...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com