A detection method for improving the resolution of area array probes

A detection method and resolution technology, which is applied in the field of ultrasonic flaw detection, can solve problems such as increased power consumption, resolution less than 1.25mm, and increased cost of flaw detectors, achieving low cost, improved sampling resolution, and clear and accurate flaw detection results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

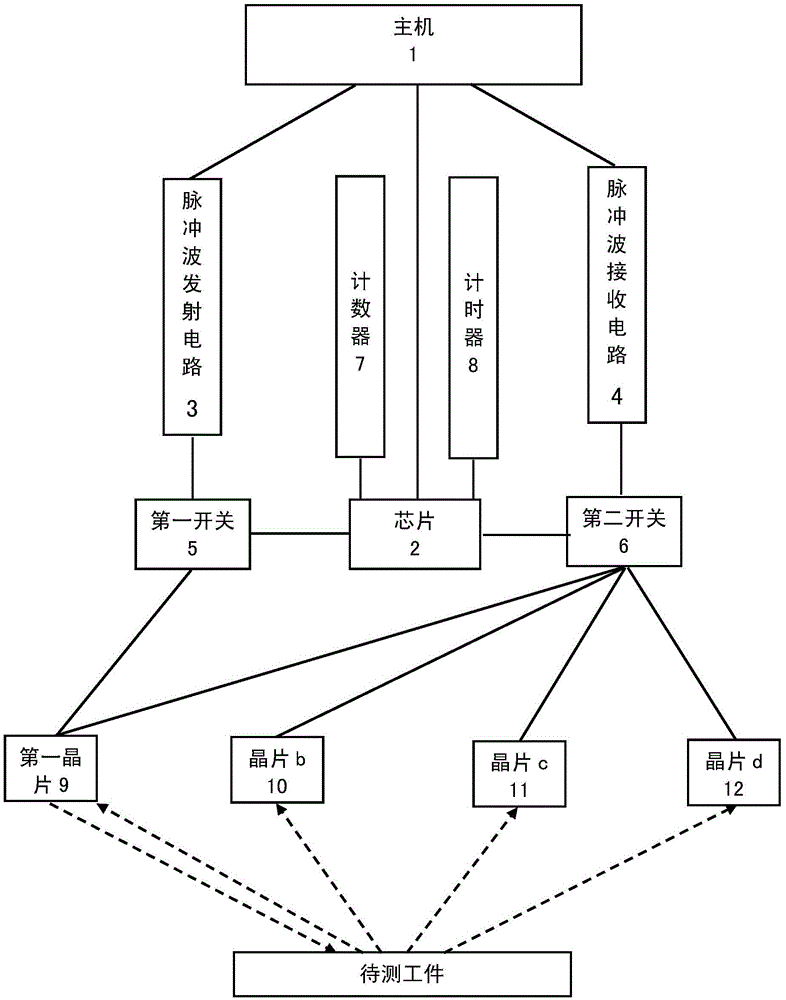

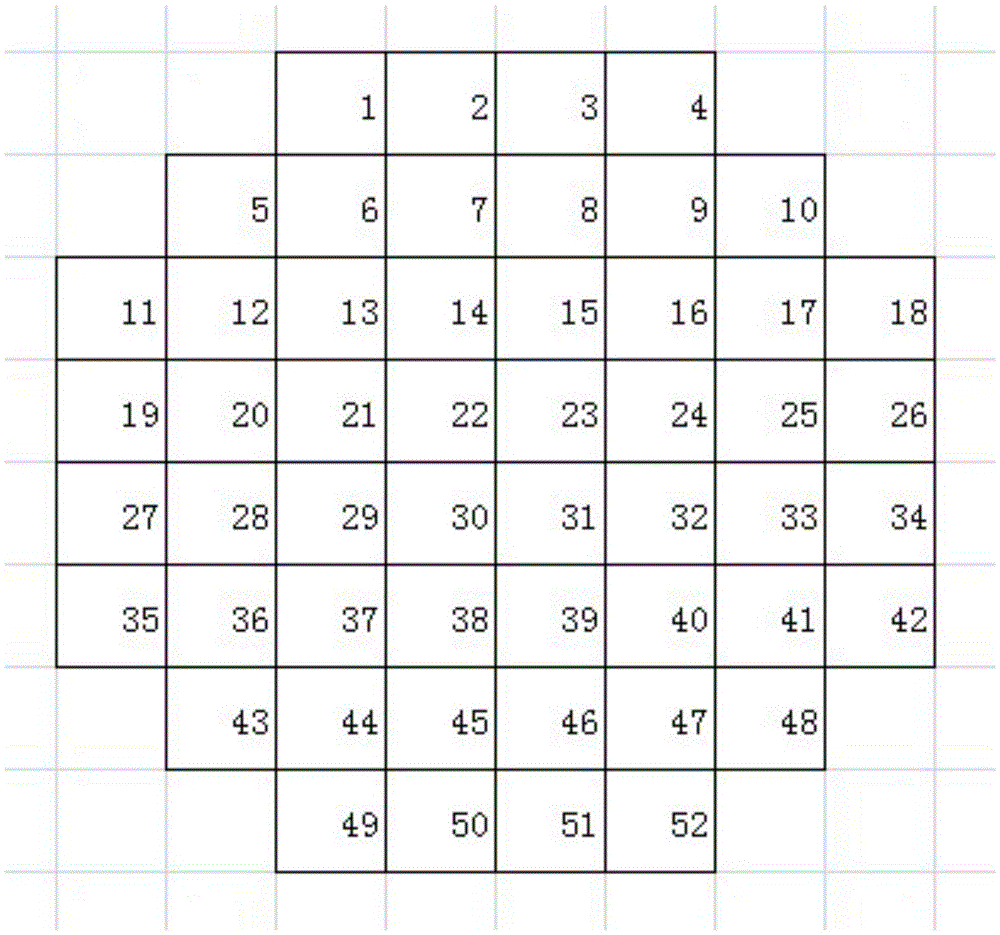

[0063] like figure 2 As shown, there are 52 chips on the ultrasonic area array probe with a diameter of 10mm, and the 52 chips are arranged in the form of an area array, and the timer 8 connected with the chip 2 presets a fixed time interval, and the chip 2 is controlled by The first switch 5 connected with the pulse wave transmitting circuit connects the pulse wave transmitting circuit 3 with the first chip 9, and the first chip 9 emits the pulse wave for the first time to the workpiece to be tested. Meanwhile, the chip 7 passes the control and The second switch 6 that the pulse wave receiving circuit 4 is connected controls the pulse wave receiving circuit 4 to be connected with the first chip 9, and the first chip 9 receives the pulse wave that the workpiece to be measured reflects back; The chip 2 sends the time signal, and after receiving the time signal, the chip 2 controls the first chip 9 to emit the second pulse wave to the workpiece to be tested. At the same time, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com