Water Cooled Electric Vehicle Charger

A technology for electric vehicles and chargers, which is applied to electric vehicles, current collectors, battery circuit devices, etc., can solve the problems of lower output accuracy and low output voltage accuracy, and achieve the effect of improving sampling accuracy and sampling resolution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

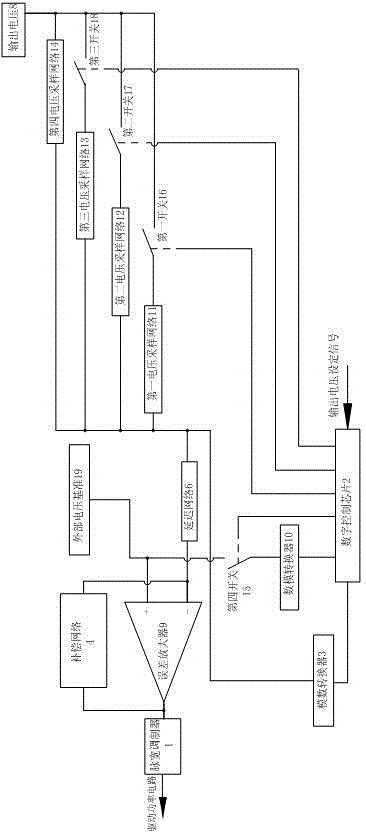

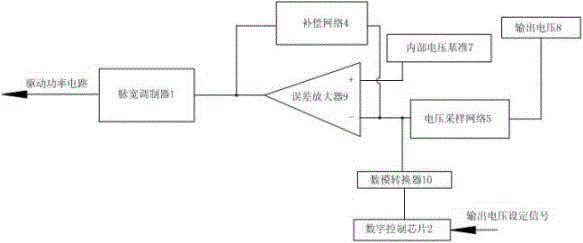

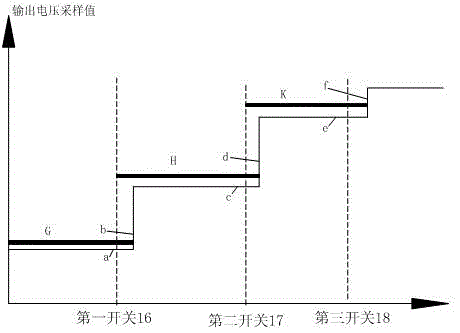

[0013] Such as figure 2 As shown, the water-cooled electric vehicle charger includes a pulse width modulator 1, a digital control chip 2, a compensation network 4 and an error amplifier 9, and the digital control chip 2, a digital-to-analog converter 10 and a fourth switch 15 are connected in series to the error amplifier 9 The positive input terminal of the amplifier 9 provides an external voltage reference 19, the negative input terminal of the error amplifier 9 is connected to the delay network 6, and the delay network 6 is connected to four voltage sampling network units connected in parallel, wherein the first A voltage sampling network unit is composed of a first voltage sampling network 11 and a first switch 16 connected to it, a second voltage sampling network unit is composed of a second voltage sampling network 12 and a second switch 17 connected to it, and the third circuit The voltage sampling network unit is made up of the third voltage sampling network 13 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com